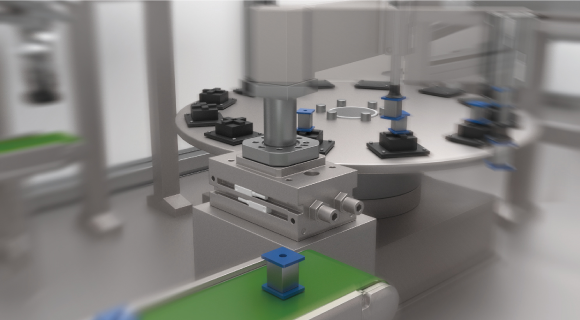

What is an oscillating process?

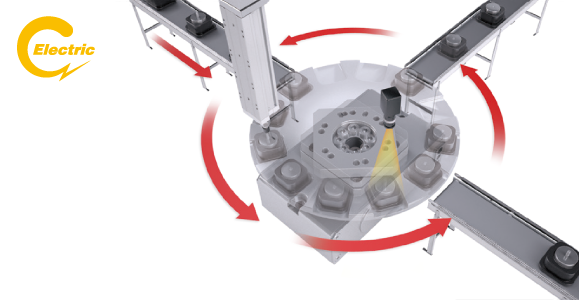

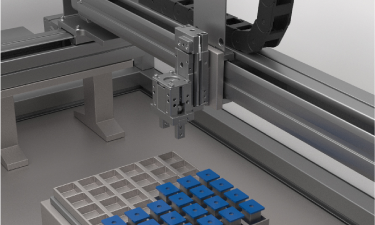

The oscillating process is a process to downsize a production line by temporarily moving the workpiece to a work table or transport table.

The key points in selecting the actuator required for the oscillating process are "Speed" and "Multi-point positioning".

Air cylinders operate at high speeds and are suitable when the speed of workpiece movement is important.

Electric actuators can be controlled, enabling multi-point positioning.

Key Points for Selection

"Speed" and "Multi-point positioning"

In the oscillating process, air cylinders are recommended for high-speed movement,

while electric actuators are recommended for multi-point positioning.

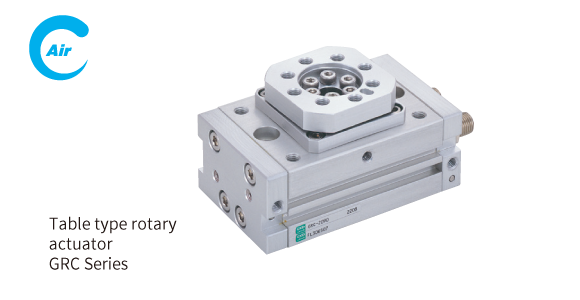

For high-speed movement Air cylinder

If multi-point positioning is required Electric actuator

If high-speed movement is required,

air cylinders are recommended.

Production efficiency for oscillating transfers is higher when high-speed movement is possible.

Air cylinders can move at high speeds even at 180 rpm.

Since the initial cost is also lower, air cylinders are recommended for high-speed movement.

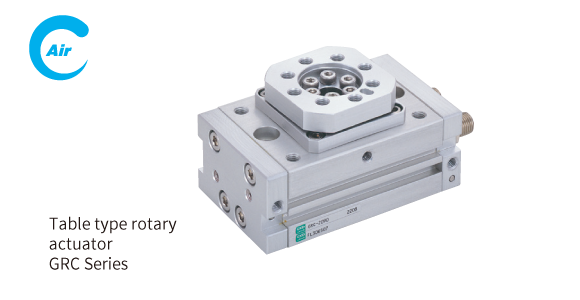

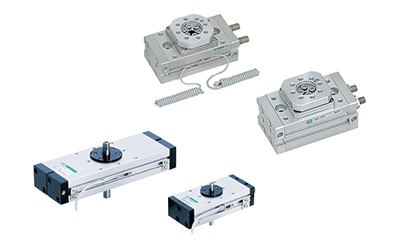

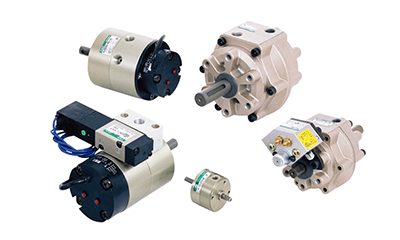

CKD Air cylinders come in a wide range of variations and are easy to select.

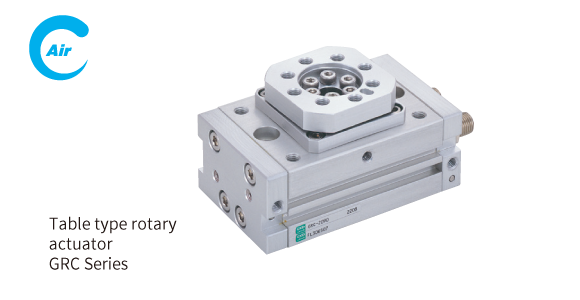

Rack and pinion type

Rotary vane mechanism

Fine speed fan rotary actuator

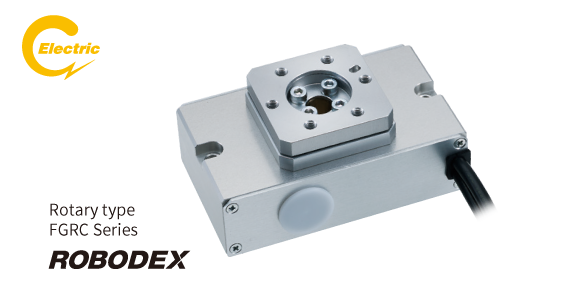

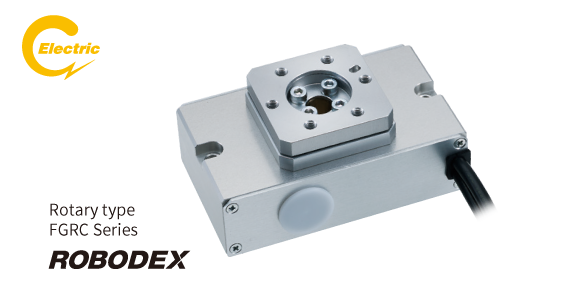

Electric actuators are recommended if multi-point positioning is required

Since electric actuators can stop at multiple points, they can be used for oscillating transfers and indexing movements of two or more points, and since they are excellent at settling, positioning adjustment at each point is easy.

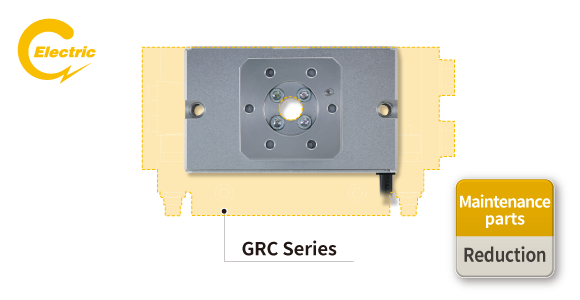

With CKD FGRC Series

The number of maintenance parts can be reduced

The electric actuator can be adjusted to any acceleration and deceleration, eliminating the need for a shock absorber and reducing the number of maintenance parts. It also reduces installation space.

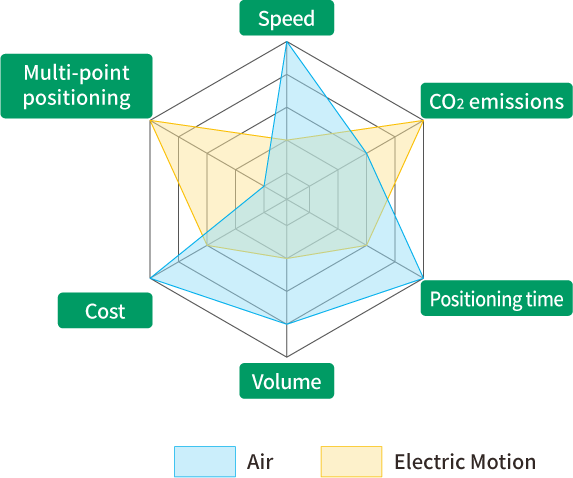

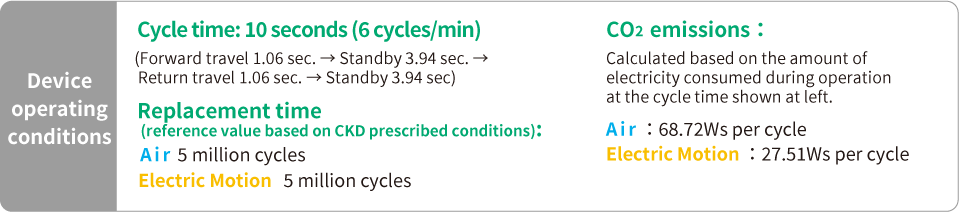

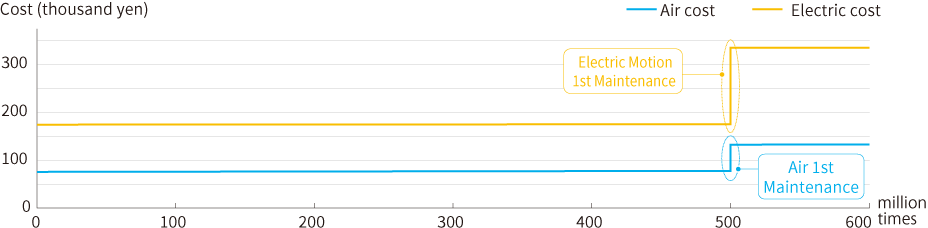

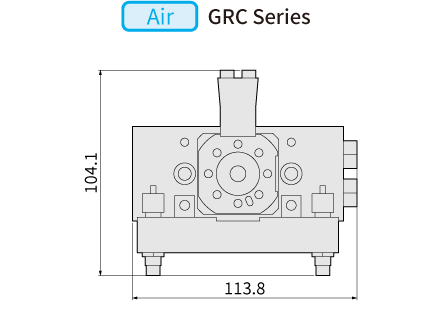

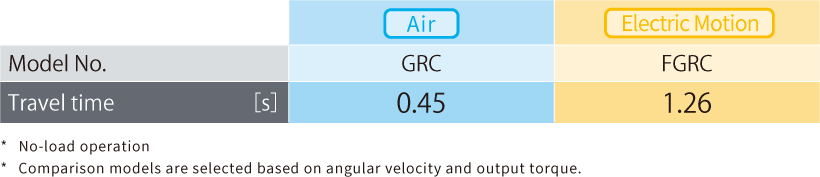

Comparison of Air Cylinder and Electric Actuators

Let's compare the cost and performance of actual models of CKD's air cylinders and electric actuators.

Model No. to compare

Air cylinder

GRC-10-180-T2H-D-A1

Electric Actuator

FGRC-30G360NCN-FS03

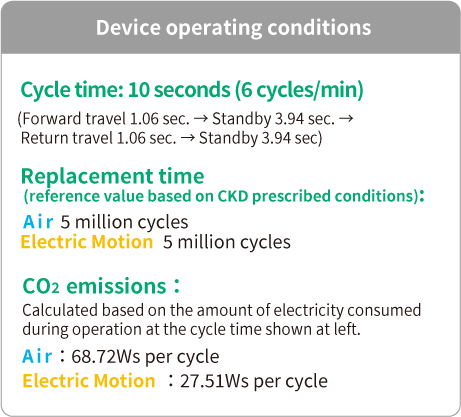

Comparison conditions

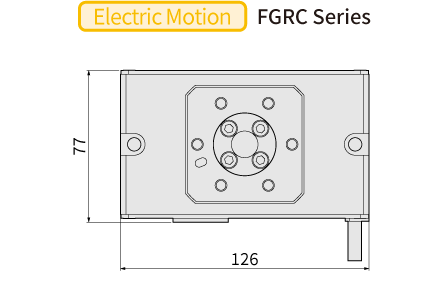

Comparison by Cost

Due to the same service life, Air with its lower initial cost, reduces total cost.

■ Calculation of costs Initial product price, product or parts price at the time of replacement, and electricity cost during operation

Electricity cost during operation: 22 yen per 1kwh.

Air is calculated by converting air consumption into electric power and combining it with the electric power consumption of solenoid valves and cylinder switches.

Labor cost for maintenance is not included.

*Replacement time is calculated based on test data under our specified conditions and is not guaranteed.

Comparison by Actuator Dimensions

Although the main body of the air is compact, it has almost the same dimensions when the shock absorber is attached.

Comparison by Positioning time

Because the acceleration/deceleration speed cannot be higher than the allowable inertia for Electric Motion, Air is faster.

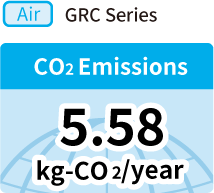

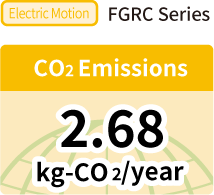

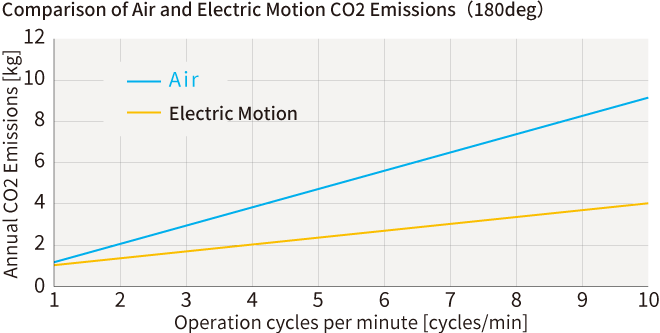

Comparison by CO2 Emissions

Even if the number of operations per minute increases, electric motors emit less CO2.

*CO2 emissions vary depending on the frequency of operation per minute.

■ Calculation of CO2 Emissions [Conditions] Annual operating days: 250 days Operation time: 8 hours/day Air pressure: 0.5MPa (clamp: 0.4MPa, conveying: 0.25MPa)

CO2 emissions converted from annual power consumption (kg-CO2/year) Annual electric power consumption (kWh) × 0.000406* × 1000*

*CO2 emission factor: Ministry of the Environment's publicized emission factors by electric utility, R2 fiscal year results Chubu Electric Power Mirise CO2 emission coefficient *1000:kg conversion

Air is calculated by converting air consumption into electric energy and adding the power consumption of solenoid valves and cylinder switches.

CKD Products

The industry's smallest motor, ø80 mm in external size and 47 mm in height, achieves a maximum torque of 1.2 N-m. It is the ideal product for processes where space has been an issue.

ABSODEX Compact (AX6000M Series)

Click here for product information Click here for product informationContact CKD for product selection

We respond to a wide range of needs, from product proposals to support, based on customer requests.

Please feel free to contact us if you have any problems in selecting an actuator.

Recommended drive method by process

Handling Process

Air cylinders are recommended if you want to lighten the hand, while electric actuators are recommended if you do not want to give impact to fragile workpieces.

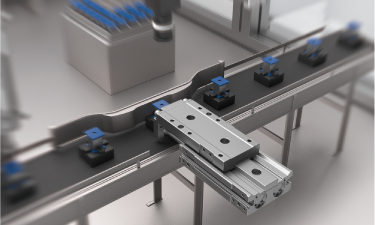

Conveying Process

Electric actuators are recommended if you want to increase positioning accuracy, while air cylinders are recommended if you want to expand the range of payload coverage.

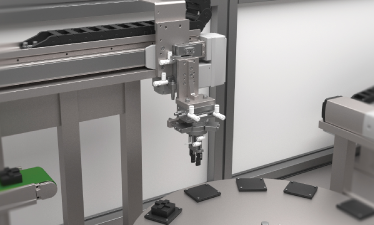

Clamping Process

The air cylinder is recommended for quick operation, and the electric actuator is recommended for shockless clamping

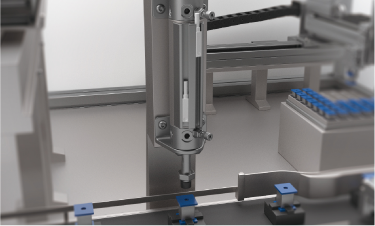

Press Fitting Process

Air cylinders are recommended for their small size and high pressing force, electric actuators are recommended for their press fitting control.

Air and Electric Motion: The Best Mix

We have prepared a demo unit that reproduces five processes, including handling,

so that you can actually see how we propose to use both Air and Electric Motion.