Features of Air and Electric Motion

First, let us introduce the features of each.

Air Cylinders

Air cylinders have the advantage of being light, inexpensive and powerful. These actuators are suitable for handling, clamping, press-fitting, etc., such as mounting on the end of a robot arm with a weight limit. They are also suitable for high-speed movement between two points and transport of heavy objects.

Electric Actuators

The greatest advantage of electric actuators is their ability to provide fine control. These actuators are suitable for transport processes requiring multi-point positioning, press-fitting requiring control, and handling of delicate workpieces.

Features of Air Cylinders

An air cylinder is a drive unit that generates power by moving a piston with compressed air.

Due to its simple structure, it is characterized by its small size and light weight.

In addition, while its mechanical features include fast movement and strong gripping force, it is not good at fine control.

There are various types of air cylinders, and it is important to select the ideal one according to the application.

Strengths of Air Cylinders

- Strong force: Strong gripping force makes it easy to transport heavy products.

- Compact: Simple mechanism enables downsizing

- Lightweight: Lightweight due to its simple structure

- Easy control program: Many ON/OFF operations, no need for complicated control programs

- High speed: High speed conveyance is possible by increasing air pressure

- Low cost: Costs can be relatively reduced compared to electric actuators

Weaknesses of Air Cylinders

- Motion control: Not good at fine control

- Transporting and positioning between multiple points: The number of components increase due to the fixed rotation accuracy.

Scenes where air cylinders are suited

Because air cylinders have strong force, they are suitable for handling workpieces that are difficult to deform, and for press fitting processes where force control is not required. Although it is not suitable for moving or controlling between multiple points, it is possible to transport and position between two points at a low cost.

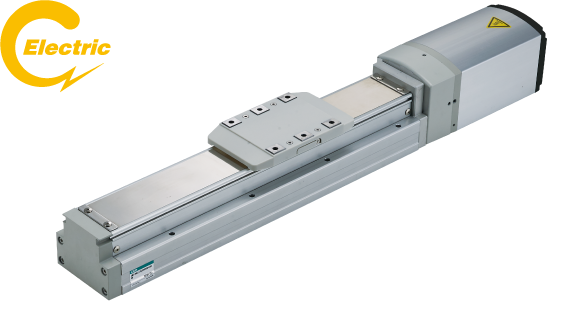

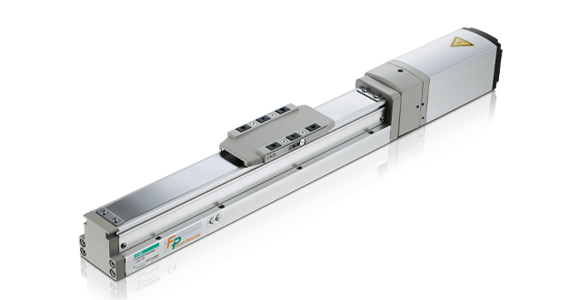

Features of Electric Actuators

Electric actuators are driving devices that utilize the rotational force of a motor.

They can perform a variety of motions including rotary motion, linear motion, and rotational motion.

The most important feature of electric actuators is that they allow fine control of motion.

The more complex the motion, the more complex the control system, but electric actuators are ideal when you want to realize any desired motion.

In addition, models equipped with a communication device can be used in IoT applications.

Advantages of Electric Actuators

- Control of motion: Easy to control acceleration and positioning.

- Applicability: A single unit can be used for a wide variety of products by changing the program.

- Maintainability: Infrequent and easy maintenance

- IoT: Models equipped with communication functions can be IoT-ready

Weakness of Electric Actuators

- Initial cost: Higher initial cost compared to air cylinders

- Complex control programs: Control programs are more complex than with air cylinders

- Size: Larger in size compared to air cylinders

Scenes for which electric actuators are suitable

Electric actuators are suited for handling easily deformable workpieces, multi-point transfer, and multi-point positioning because their movements can be finely controlled. They are also good at controlling force in the press-fitting process because of their ability to change acceleration. Furthermore, models equipped with communication devices have the advantage of being able to support IoT.

Recommended drive method by process

Handling Process

Air cylinders are recommended if you want to lighten the hand, while electric actuators are recommended if you do not want to give impact to fragile workpieces.

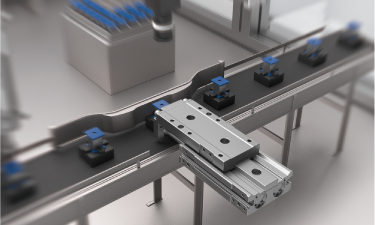

Conveying Process

Electric actuators are recommended if you want to increase positioning accuracy, while air cylinders are recommended if you want to expand the range of payload coverage.

Clamping Process

The air cylinder is recommended for quick operation, and the electric actuator is recommended for shockless clamping

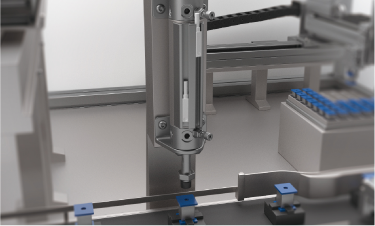

Press Fitting Process

Air cylinders are recommended for their small size and high pressing force, electric actuators are recommended for their press fitting control.

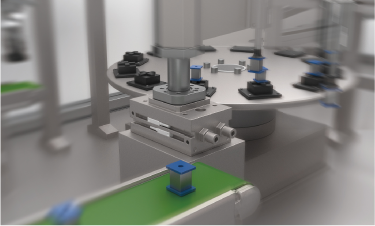

Oscillating Process

Air cylinders are recommended for their high-speed movement, and electric actuators are recommended for positioning control, such as multi-point positioning

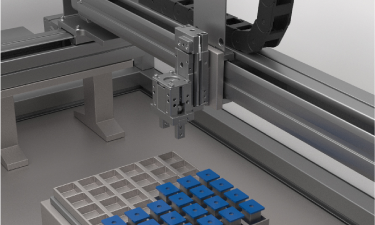

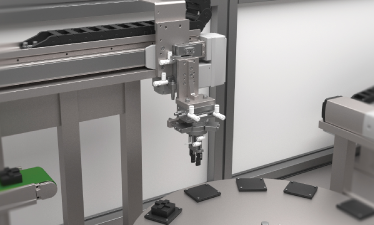

Air and Electric Motion: The Best Mix

We have prepared a demo unit that reproduces five processes, including handling,

so that you can actually see how we propose to use both Air and Electric Motion.