Support for selecting the best actuator

Features of Air and Electric Motion

First, let us introduce the features of each.

Air Cylinders

Air cylinders have the advantage of being light, inexpensive and powerful. These actuators are suitable for handling, clamping, press-fitting, etc., such as mounting on the end of a robot arm with a weight limit. They are also suitable for high-speed movement between two points and transport of heavy objects.

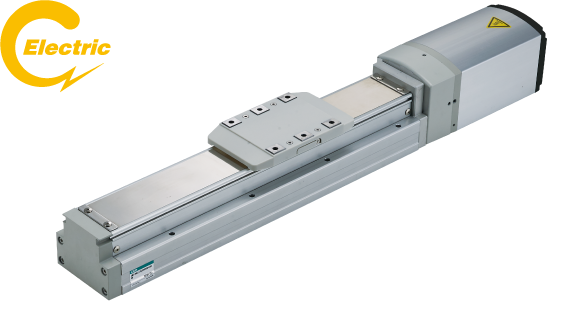

Electric Actuators

The greatest advantage of electric actuators is their ability to provide fine control. These actuators are suitable for transport processes requiring multi-point positioning, press-fitting requiring control, and handling of delicate workpieces.

Recommended drive method by process

CKD, which manufactures both air cylinders and electric actuators and uses them at its own production sites,

introduces the following selection points based on a total assessment of each process,

including functions and cost, while also taking CO2 emissions into consideration.

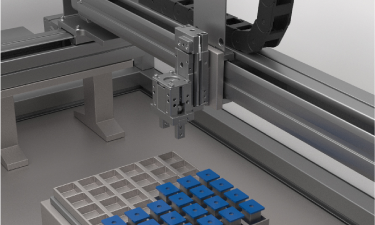

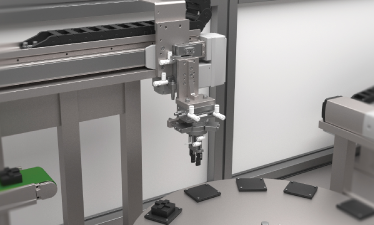

Handling Process

Air cylinders are recommended if you want to lighten the hand, while electric actuators are recommended if you do not want to give impact to fragile workpieces.

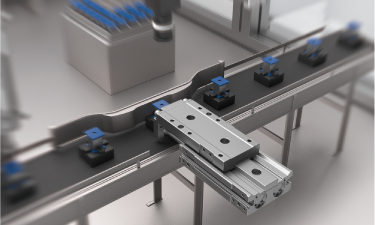

Conveying Process

Electric actuators are recommended if you want to increase positioning accuracy, while air cylinders are recommended if you want to expand the range of payload coverage.

Clamping Process

The air cylinder is recommended for quick operation, and the electric actuator is recommended for shockless clamping

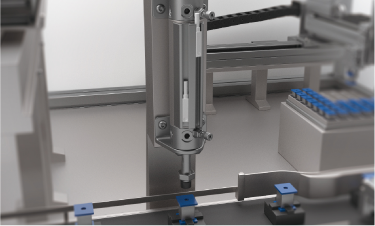

Press Fitting Process

Air cylinders are recommended for their small size and high pressing force, electric actuators are recommended for their press fitting control.

Oscillating Process

Air cylinders are recommended for their high-speed movement, and electric actuators are recommended for positioning control, such as multi-point positioning

Solution Proposal

We offer solutions to the problems we often receive inquiries

about Air and Electric Motion components.

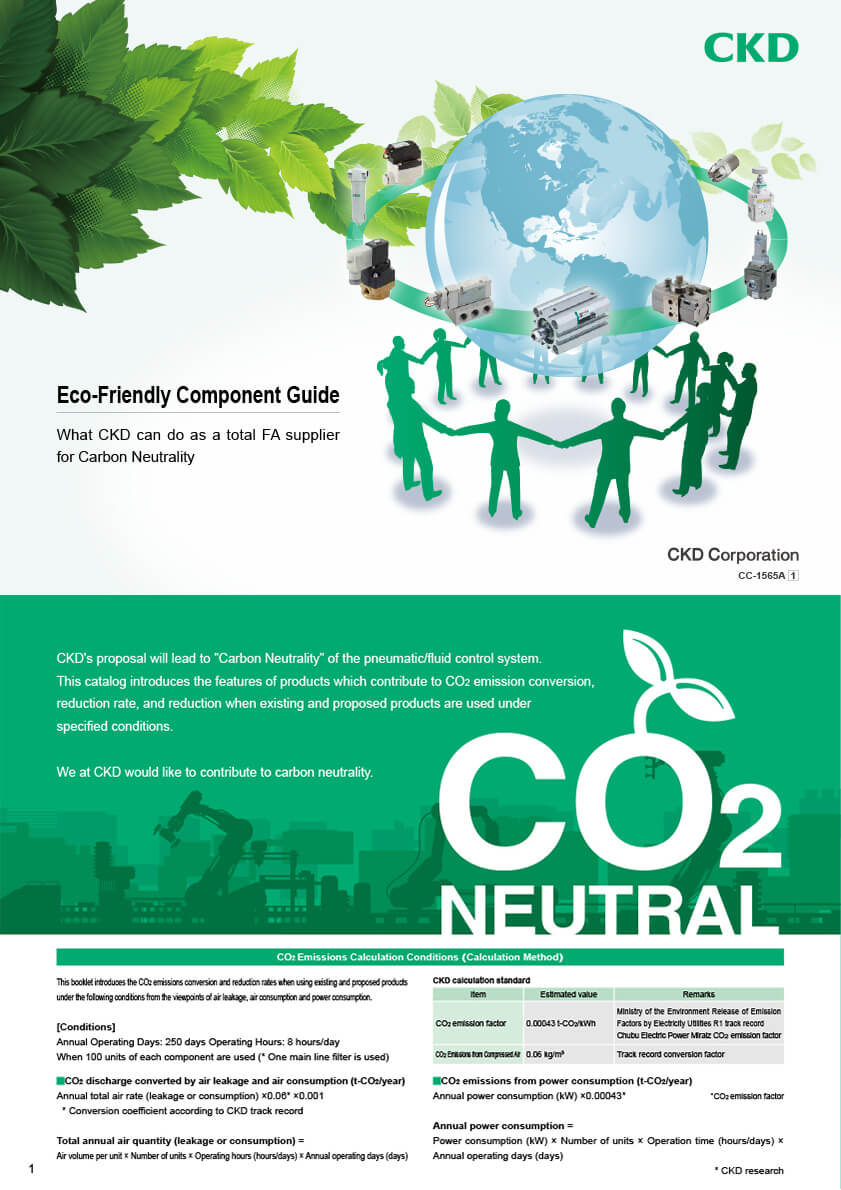

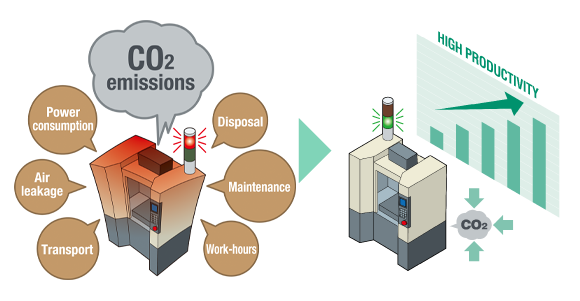

Decarbonization

We can solve your problems of achieving decarbonization without making major changes to your existing equipment.

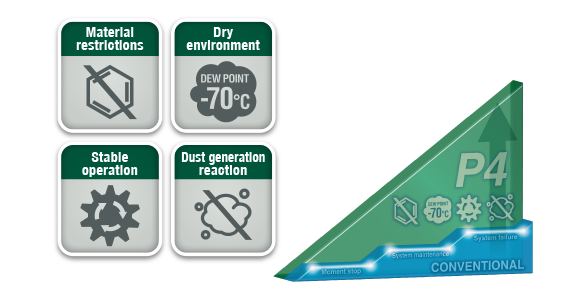

Use in ultra dry air, dry environments, etc.

Solves the problem of long-term stable operation under harsh conditions, such as dry environments.

Convert designs from Air to Electric Motion

If you want to convert air cylinders to electric motion, we offer not only our products but also our know-how.

Simplified periodic maintenance

Maintenance work is greatly reduced by converting to components that are easy to maintain.

Catalog Download

For a variety of environments and applications,

detailed information on Air and Electric Motion components can be found here.

Best Mix Air & Electric Demo Unit Tour

We have reproduced 5 processes such as handling introduced on this page,

and prepared a video that you can actually see our proposals for using air cylinders and electric actuators.

Best Mix Demo Unit

This demonstration uses an electric actuator that specializes in multi-point positioning, and a light air hand, combining the best features of both.

ALL Air Demo Unit

This is a demonstration using all pneumatic components. Light and quick operation can be achieved.

ALL Electric Demo Unit (1)

This is a demonstration using all electric motion components. Since air is not used, CO2 emissions can be reduced.

ALL Electric Demo Unit (2)

This is a demonstration using all electric motion components. Smooth and stable operation can be achieved even with increased work speed.