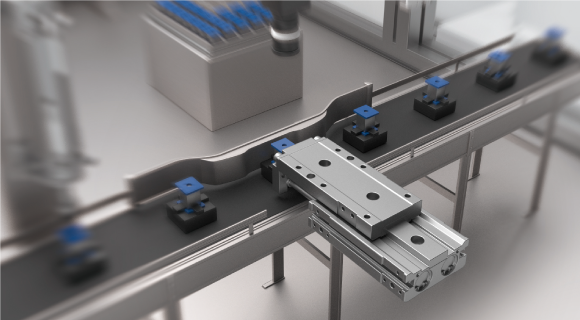

What is the clamping process?

The clamping process is used to safely and accurately clamp a part or material in a specific position.

This process serves to assist in press fitting, shape changing, inspection, assembly, and other operations where the workpiece is prone to movement.

The key points in selecting the actuator required for the clamping process are "clamping speed" and "shockless".

Air cylinders are suitable for clamping hard workpieces because of their high force and fast motion.

Electric actuators can clamp soft workpieces without shock due to their controllable motion.

Key Points for Selection

"Speed" and "Shockless"

Air cylinders are recommended for high clamping speeds,

while electric actuators are recommended for shockless clamping.

For shock absorbing Electric Actuator

Air cylinders are recommended for quick operation

For production efficiency, the faster the clamping speed, the better.

Air cylinders have a short actuation time, contributing to shorter equipment tact time.

If speed is a priority, we recommend Air cylinders with high clamping force, small size, and low cost.

Air cylinders also save energy because their power consumption does not increase even if the clamping time becomes longer.

CKD Air cylinders come in a wide range of variations and are easy to select.

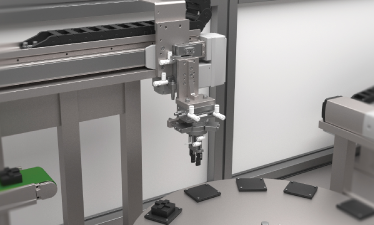

Rotary clamp cylinder

Compact cylinder

Compact cylinder

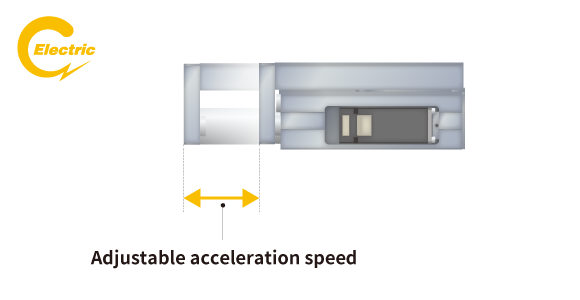

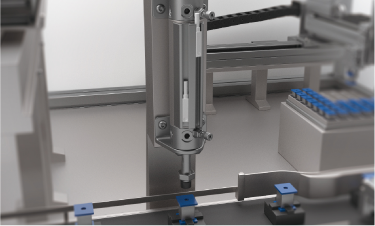

An Electric actuator is required for soft clamping

With electric actuators, acceleration and deceleration can be adjusted as desired, enabling shockless clamping.

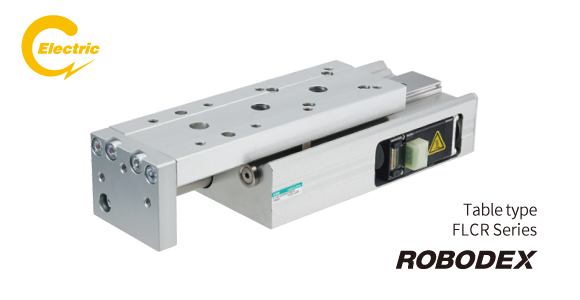

With CKD FLCR Series

The number of maintenance parts can be reduced

The compact design with a built-in motor and the ability to adjust acceleration/deceleration as desired eliminates the need for a shock absorber and reduces the number of maintenance parts.

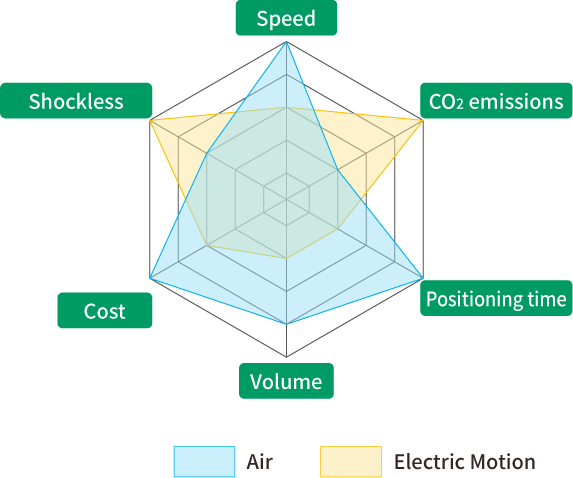

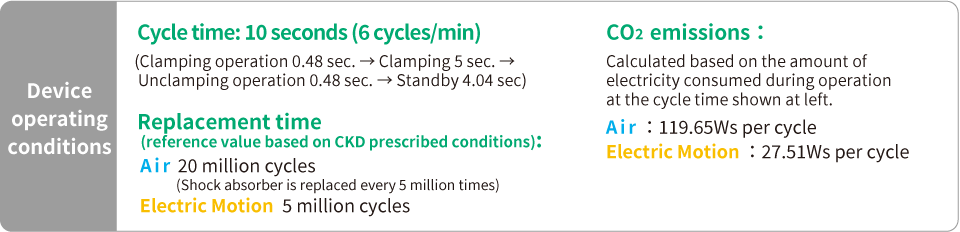

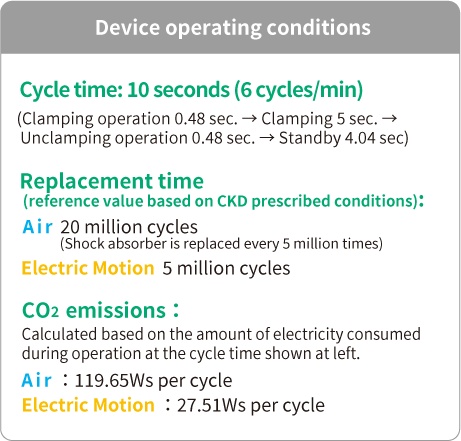

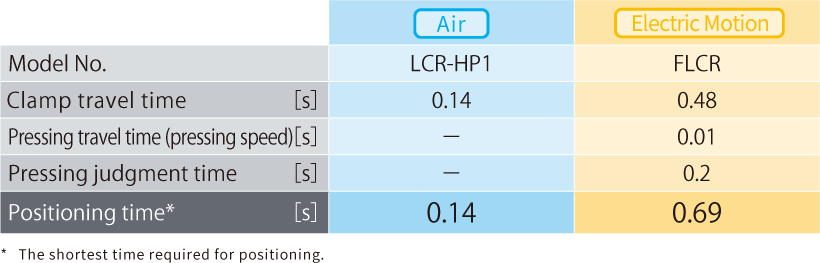

Comparison of Air Cylinder and Electric Actuators

Let's compare the cost and performance of actual models of CKD's air cylinders and electric actuators.

Model No. to compare

Air cylinder

LCR16-50-T2H-D-A5-HP1

Electric Actuator

FLCR-20G02050NCN-RS03

Comparison conditions

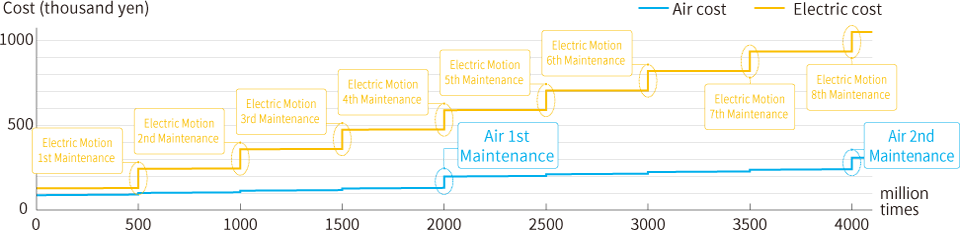

Comparison by Cost

If the high-durability Component LCR-HP1 Series is used,

the frequency the air component is replaced is reduced, enabling cost reduction.

■ Calculation of costs Initial product price, product or parts price at the time of replacement, and electricity cost during operation

Electricity cost during operation: 22 yen per 1kwh.

Air is calculated by converting air consumption into electric power and combining it with the electric power consumption of solenoid valves and cylinder switches.

Labor cost for maintenance is not included.

*Replacement time is calculated based on test data under our specified conditions and is not guaranteed.

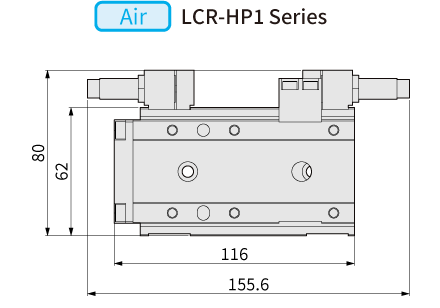

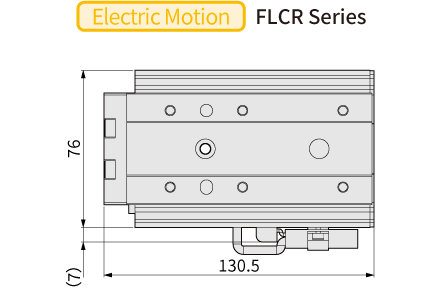

Comparison by Actuator Dimensions

Although the main body of the air is compact,

it has almost the same dimensions when the shock absorber is attached.

Comparison by Positioning time

Air LCR-HP1 Series is faster since it operates between 2 points.

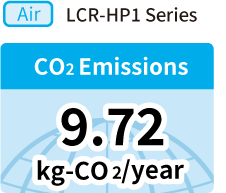

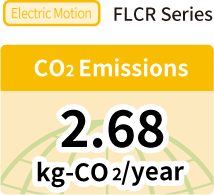

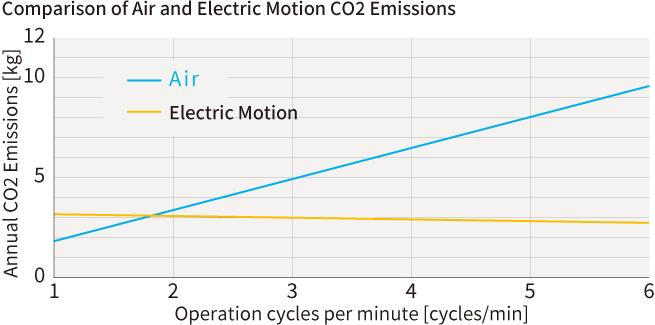

Comparison by CO2 Emissions

Even if the number of movements per minute increases,

the CO2 emission of electric does not change much.

*CO2 emissions vary depending on the frequency of operation per minute.

*The longer the clamping time, the more power consumption and CO2 emissions for Electric Motion.

■ Calculation of CO2 Emissions [Conditions] Annual operating days: 250 days Operation time: 8 hours/day Air pressure: 0.5MPa (clamp: 0.4MPa, conveying: 0.25MPa)

CO2 emissions converted from annual power consumption (kg-CO2/year) Annual electric power consumption (kWh) × 0.000406* × 1000*

*CO2 emission factor: Ministry of the Environment's publicized emission factors by electric utility, R2 fiscal year results Chubu Electric Power Mirise CO2 emission coefficient *1000:kg conversion

Air is calculated by converting air consumption into electric energy and adding the power consumption of solenoid valves and cylinder switches.

CKD Products

This single-guide type of rotary clamp cylinder combines rotary and linear motion to save space. The overall length is significantly shorter than the conventional double guide type (RCC2 series), which is highly regarded for its high rigidity. It is possible to use either the single guide type or the double guide type depending on the shape of the clamp lever and the cylinder operating speed.

Air clamp cylinder RCS2 Series

Click here for product information Click here for product informationContact CKD for product selection

We respond to a wide range of needs, from product proposals to support, based on customer requests.

Please feel free to contact us if you have any problems in selecting an actuator.

Recommended drive method by process

Handling Process

Air cylinders are recommended if you want to lighten the hand, while electric actuators are recommended if you do not want to give impact to fragile workpieces.

Conveying Process

Electric actuators are recommended if you want to increase positioning accuracy, while air cylinders are recommended if you want to expand the range of payload coverage.

Press Fitting Process

Air cylinders are recommended for their small size and high pressing force, electric actuators are recommended for their press fitting control.

Oscillating Process

Air cylinders are recommended for their high-speed movement, and electric actuators are recommended for positioning control, such as multi-point positioning

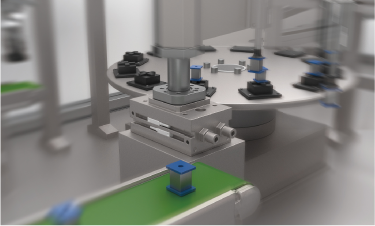

Air and Electric Motion: The Best Mix

We have prepared a demo unit that reproduces five processes, including handling,

so that you can actually see how we propose to use both Air and Electric Motion.