News

- HOME

- News

- Release of 3 Grippers Models for Collaborative Robots Certified by TechMan Robot Inc. and OMRON Corp

Release of 3 Grippers Models for Collaborative Robots Certified by TechMan Robot Inc. and OMRON Corp

September 30, 2020

Release of 3 Grippers Models for Collaborative Robots

Certified by TechMan Robot Inc. and OMRON Corp

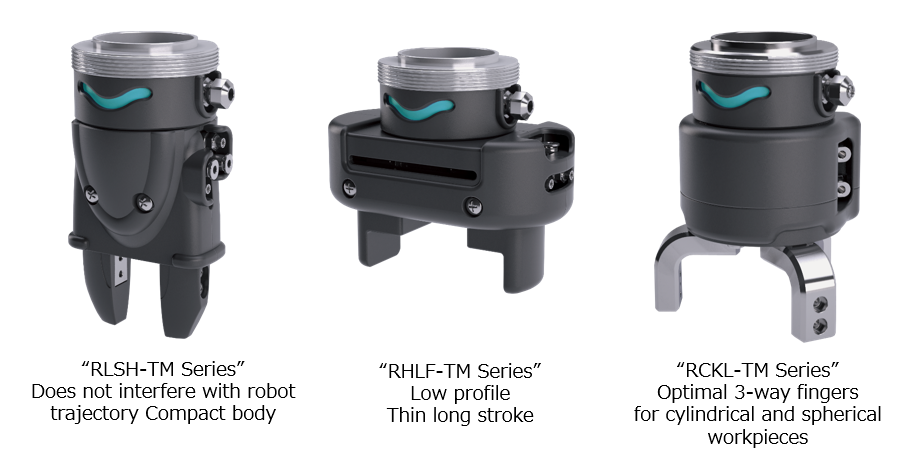

CKD Corporation (Headquarters: Komaki City, Aichi, and President: Kazunori Kajimoto) has released 3 models of grippers for collaborative robots — “RLSH-TM Series, RHLF-TM Series and RCKL-TM Series” — on October 1, 2020.

For the first time in a Japanese company has acquired certification as a pneumatic gripper, by custom-made products TechMan Robot Co., Ltd. (Headquarters: Taiwan) and OMRON Corporation (Headquarters: Shimogyo Ward, Kyoto Prefecture), where Collaborative robots TM Series enables Plug & Play (*1).

*1 Plug & Play: OS automatically sets the required settings when a peripheral Component, etc., is connected to the PC.

1. Background to development

In addition to the ever-increasing shortage of workers, the need for automation at manufacturing sites looking to the“after-Covid-19 era”is increasing.Collaborative robots that can share the workspace with people without any safety fences are attracting attention as equipment capable of automating manufacturing sites of all sizes.

2. Major applications

(1) Supply and removal of parts from machinery (machine tending)

(2) Parts conveyance (Pick & Place)

(3) Product assembly

3. Product features

(1) Can be easily mounted on robots

The gripper can be connected to its dedicated flange, clamp ring, and wiring connector to the robot in three steps, and in just 5 minutes. In addition, the gripper setup can be changed without using any tools by utilizing the dedicated flange to save time.

(2) Safe and user-friendly design

A round-shaped resin body that has no protrusions or edges, is used to ensure operator safety. A 360°visible indicator lamp allows workers near the robot to check the operation status at a glance.

(3) Easy-to-use air drive

Because it is air driven, it is compact and lightweight, yet exhibits high gripping force. Gripping power and speed can be easily set with an external regulator and built-in speed controller, respectively.

(4) Teaching supported with dedicated software

Since teaching and control can be easily performed from the dedicated software on the robot side, the operation setting time of the gripper can be shortened.

(5) Lineup according to usage environment and usage

4. Main specifications

(1)Model : Compact “RLSH -TM Series”

Bore size : φ20(mm)

Stroke : 18 (mm)

Gripping power : 42 (N)

(2)Model : Long stroke “RHLF-TM Series”

Bore size : φ16 x 2(mm)

Stroke : 32(mm)

Gripping power : 85 (N)

(3)Model : 3-way jaw “RCKL -TM Series”

Bore size : φ40(mm)

Stroke : 10(mm)

Gripping power : 125 (N)

5. Retail prices (tax excluded)

Compact type “RLSH-TM Series” :308,000 yen to 388,000 yen

Long stroke type “RHLF-TM Series” :345,000 yen to 435,000 yen

3-way fingers type “RCKL-TM Series” :326,000 yen to 412,000 yen

6. Sales planning(3 years later)

16 million yen

7. Release Date

October 1, 2020