Specific Use<P4 * series for Rechargeable battery manufacturing process>

The P4 Series contributes to all the needs of rechargeable batteries and next-generation battery manufacturing processes

We consistently meet the needs of rechargeable battery manufacturing from production stability of the evolving rechargeable battery and next-generation battery manufacturing processes to electrode production and packaging.

Restrict materials for component parts

Restricts the use of materials and surface treatments inappropriate for the rechargeable battery manufacturing process.

Long service life even in ADP-80°C dew point environments

A diverse lineup compatible with ultra-low dew point atmospheres (including supply air). We develop grease suitable for next-generation battery processes to maximize performance. Lubrication of the sliding part is maintained for long periods, even in dry environments.

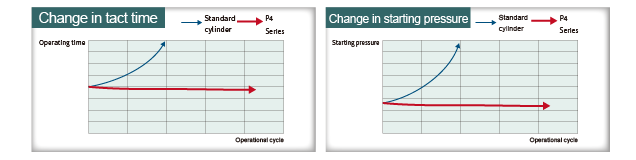

Contributing to a system that never stops

Uses a special grease that supports low dew points and high frequency use. Contributes to stable operation of equipment.

Suppresses dust generation of metal wear powder

Equipped with a local exhaust function (vacuum treatment port). Prevents contamination of the electrodes or cell by not leaking the metal wear powder outside

Long service life in dusty environments

Equipped with a heavy duty scraper and lube keeper to prevent intrusion of dust and to maintain lubrication. This greatly improves durability in dusty environments.