Dust-Resistant Components

CKD’s Component Series for Dust-Prone Food Production Environments

Introducing CKD's component products designed for reliable operation in environments with airborne food particles.

If you have this problem

-

- Problem 01

- Want to use air cylinders or electric actuators in a dusty environment?

-

- Problem 02

- Want to use remote I/O or solenoid valves in a dusty environment?

-

- Problem 03

- Want an easy way to supply nitrogen in a dusty environment?

Product Features

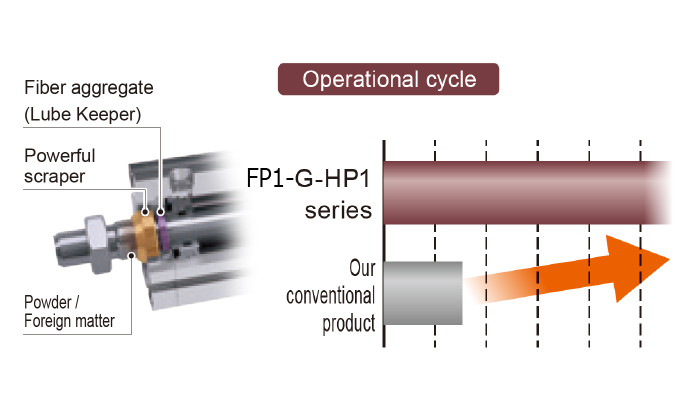

The FP1-G-HP Series: An Environment-Resistant Cylinder Built for Dust-Prone Food Production

The FP1-G-HP Series features a heavy-duty scraper and lube-keeping structure, effectively preventing dust ingress and maintaining lubrication. Its durability in dust-prone environments is over four times greater than conventional cylinders, ensuring a long service life. The use of food-grade (NSF H1) lubricants makes it ideal for reliable use in food production processes.

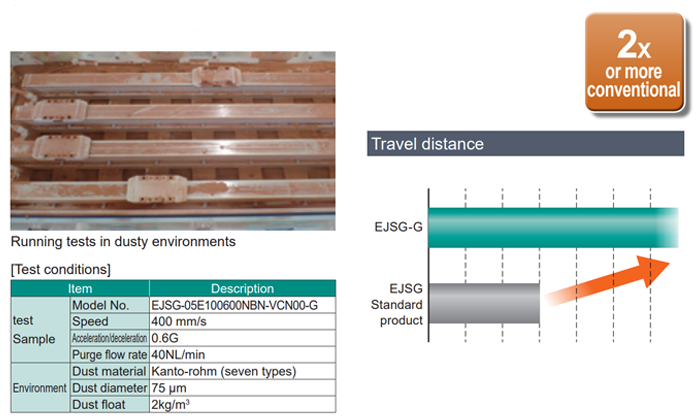

EJSG-G Series: A Long-Life Electric Actuator for Dust-Prone Environments

The EJSG-G Series electric actuator features IP50 protection. The pressurizing port and connector cover significantly extend the travel distance in dusty environments, more than doubling the lifespan compared to standard models.

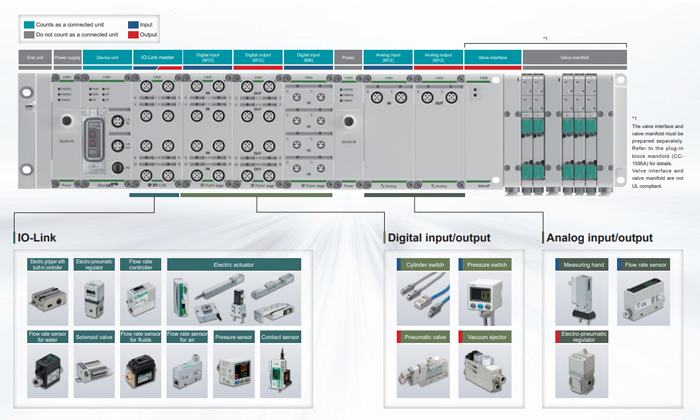

Direct Installation in Dust-Prone Environments: Remote I/O RT Series & Solenoid Valve TVG Series

The robust IP65/67 (dust-proof/jet-proof) design of the Remote I/O RT Series and TVG Series Solenoid Valve allows for direct installation near the actuator without the need for an enclosure. This eliminates the need for a control panel, enhancing layout flexibility.

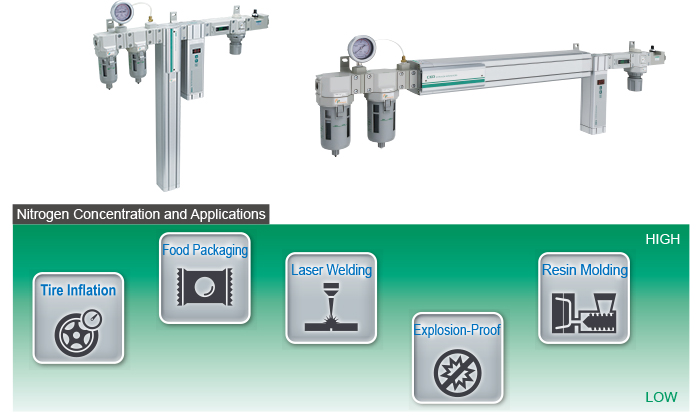

The NS Series Nitrogen Gas Generator Unit: Safe for use even in dusty environments!

The NS Series Nitrogen Gas Generator Unit easily separates and generates the nitrogen needed for applications like explosion protection, right from your compressed air.

Supplying nitrogen prevents combustion and explosions in environments with flammable dust.

Additionally, you can select the optimal system for your required flow rate and concentration, and easily modify it later thanks to its modular connections.

Supplying nitrogen prevents combustion and explosions in environments with flammable dust.

Additionally, you can select the optimal system for your required flow rate and concentration, and easily modify it later thanks to its modular connections.

Frequently Asked Questions

-

What is the difference between IP50 and IP65 specifications?

IP50 offers dust resistance, while IP65 provides complete dust-proof protection. For dusty environments, the IP50 electric actuator provides a cost-effective solution compared to the IP65 specification.

Product Introduction Page

Electric actuator Slider type EJSG Series

This electric actuator can be used safely in the food manufacturing process. Made-to-order actuators are available to meet a variety of requirements.

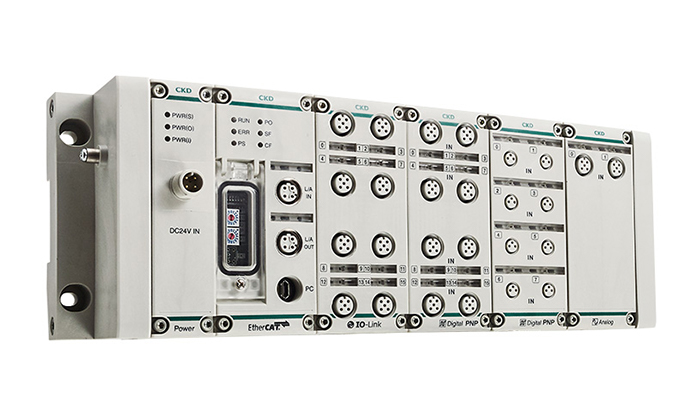

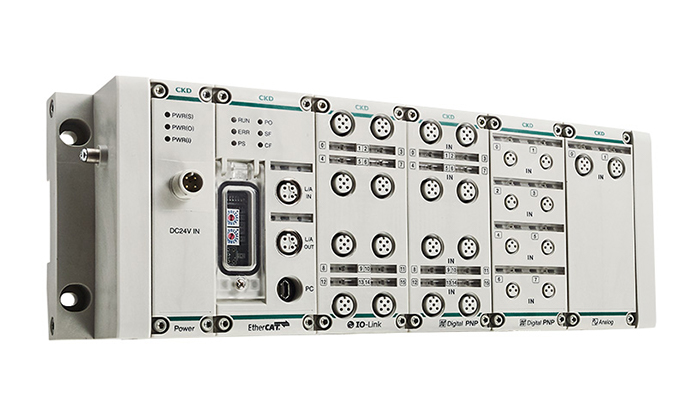

Remote I/O RT Series

Waterproof remote I/O compatible with digital I/O, analog I/O and IO-Link master. Up to 18 units can be added for use. Diagnosis information (overcurrent, short-circuit, error, etc.) can be acquired, contributing to the IoT of equipment.

Pilot operated 3, 5-port valve Plug-in-type block manifold TVG Series

Plug-in valve designed to be carbon neutral, highly reliable, and easy to use. Durability of 120 million cycles. Minimal air leakage even after long-term use. While the equipment is not in operation, air leakage is minimized to help reduce CO2 emissions.

Nitrogen Gas Generator Unit NS Series

A unit that easily generates nitrogen gas without the need for cylinders or large-scale equipment.

Can be installed anywhere, and the optimal model can be selected from a lineup of 17 flow rates and 25 models.

Safe and reliable for use in food manufacturing processes.

Can be installed anywhere, and the optimal model can be selected from a lineup of 17 flow rates and 25 models.

Safe and reliable for use in food manufacturing processes.

CONTACT

×

×

Dust-Resistant Components

×