The History of

Fine System's Technological Passion

We'll show you the history of CKD, which has been long trusted by

cutting-edge equipment manufacturers of semiconductors and other equipment manufacturers.

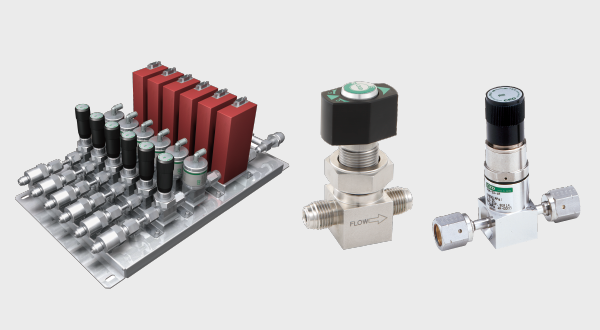

In 1987, in order to ensure the sealability of the component connection, one of the important elements of the chemical process of semiconductors, CKD released the first valve model which was integrated with a high-sealable fitting. In addition, we developed a new series of products, such as those with an expanded fluid temperature and pressure ranges to meet the demands of our growing customers. Even today, as the semiconductor process advances, the precision and cleanliness required for the chemical handling components are becoming increasingly strict, and the product development has been repeated to meet the customer's needs, gaining the support of many customers.

For diaphragms, one of the core components, CKD consistently conducts procuring materials to molding and to stabilize product quality. It also provides high cleanliness in both design and production and is keeping up with the evolving refinements of the semiconductor circuits. These high quality products have been highly evaluated and many of them have been adopted by world-class semiconductor equipment and facility makers.

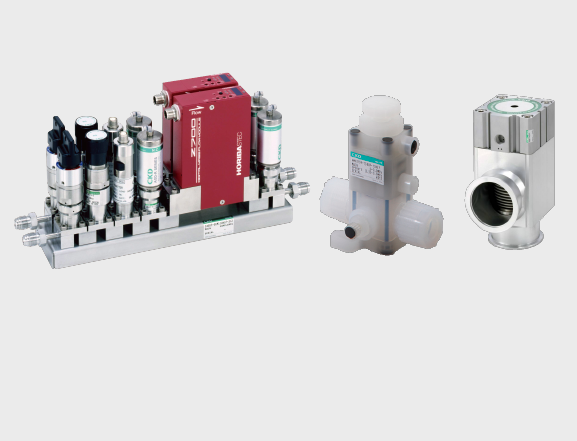

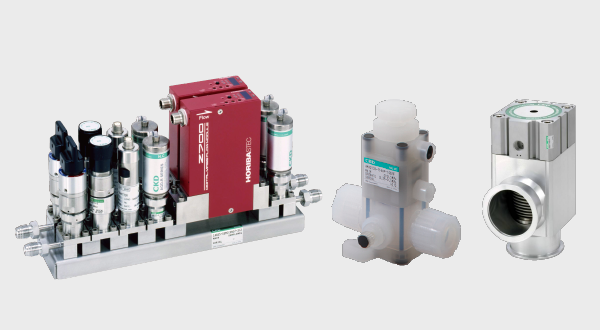

Now, integrated gas supply systems are widely used in advanced semiconductor processes. To meet the growing sophistication of semiconductor deposition machines & etching machines and to reduce their footprint, we have made efforts to quickly develop compact components. By combining these integration technologies and CKD's broad range of gas control components, the Clean Panel (FSP Series) was also released. It is highly used by many customers for N2 purge purposes.

By utilizing our unique manufacturing method of the diaphragm, one of the core parts of the valve, and utilizing the know-how of pneumatic cylinder technology, CKD developed the ALD valve which achieves high durability. These products support the evolving semiconductor deposition processes.

In order to reduce the weight of the entire equipment, CKD has reviewed materials and structures of vacuum valves and developed it as a core products by improving the durability of bellows. To meet the need for advanced vacuum pressure control, such as slow exhaust control, CKD developed a proprietary Vacuum Pressure Proportional Control System (VEC) by applying our own air pressure control technology. It is now an integral item of semiconductor processes around the world.

This technology has been applied to release a more General-Purpose Vacuum Pressure Control System (IAVB Release) and is available to a number of customers not only from the semiconductor industry who require vacuum processes.

Front End Process

We have a wide range of cutting-edge equipment that can accommodate the sophistication of the process.

Chemical Facility

The high pressure, high-concentration liquid valve, and the liquid supply equipment provide a wide range of variations that can be used without worries.

Gas Facility

Meet your needs in the process gas supply with a product line tailored to your size and budget.