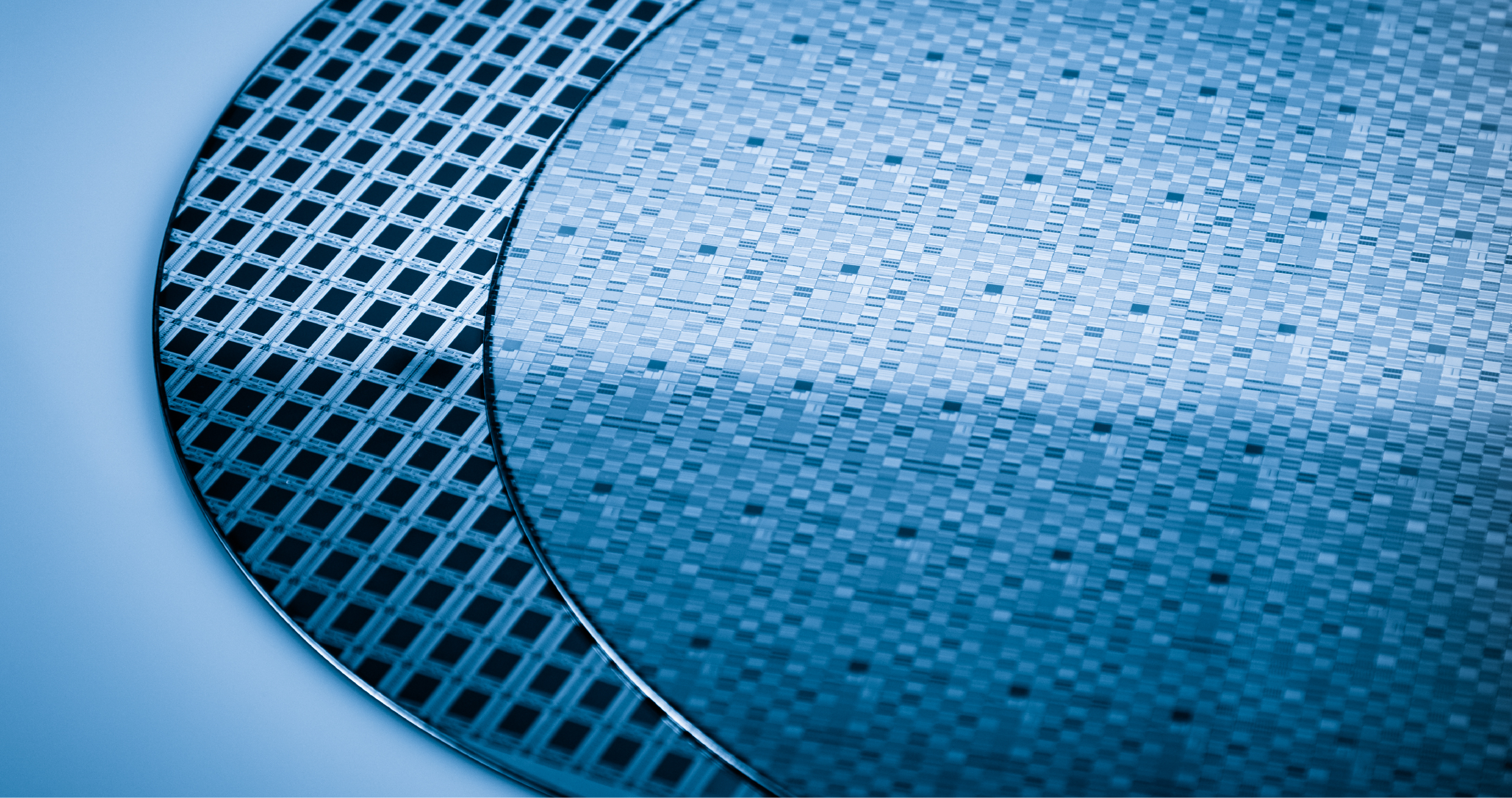

Total solution for semiconductor manufacturing

Products by Front End Process

Search each semiconductor manufacturing process for the product you are looking for.

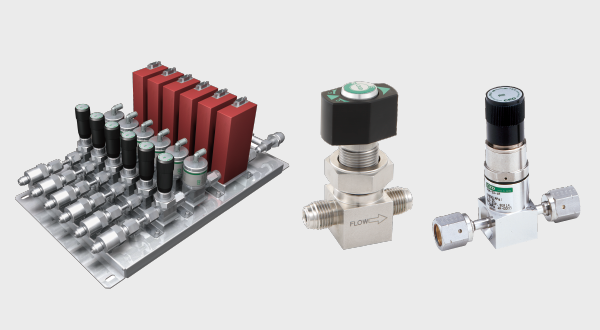

Chemical Facility

The high pressure, high-concentration liquid valve, and the liquid supply equipment provide a wide range of variations that can be used without worries.

Gas Facility

Meet your needs in the process gas supply with a product line tailored to your size and budget.

History of Fine Technology

CKD will continue to challenge new product development based on the numerous achievements and experience we have gained over the history of semiconductor manufacturing.