-

- Inspection Machine

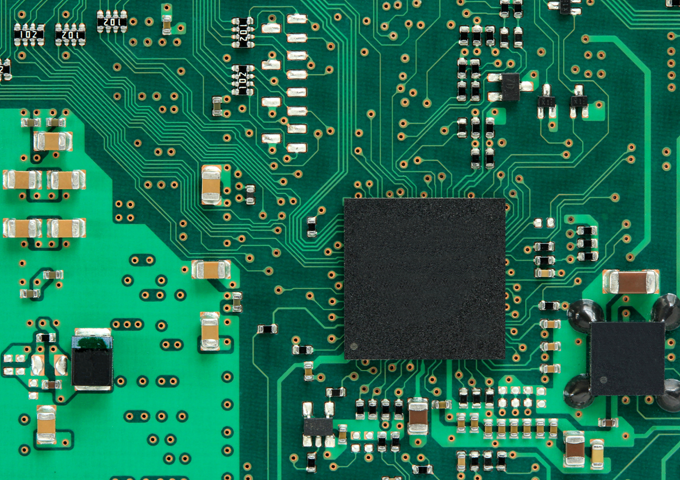

- Inspection for Printed Circuit Board

Solder Paste

Inspection Machine

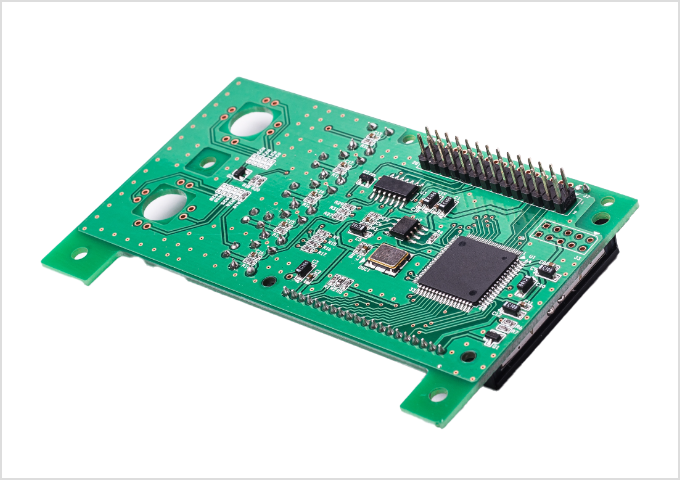

VP SeriesPrinted Circuit Boards (PCBs) are essential for a prosperous society. CKD’s inspection equipment supports that quality as well. In addition to the high speed/high precision inspection performance that has the top share in the industry, the design that enhances the beauty of the work environment has also been highly evaluated.

Top share in the Printed Circuit Board (PCB) production industry. The inspection machine that improves the overall quality of PCB.

For PCBs of smartphones and automotive components, Monitoring the volume and height of solder paste is important. By conventional 2D inspection or 3D laser inspection methods, correct solder condition from PCB surface as 0 μm, which is considered difficult, can be inspected with this product. (※on the specification by super-fine resolution)

A reduction in the inspection speed which is likely to occur in high-definition solder inspection is optimized as the maximum speed by a multi-inspection function for switching three types of resolution in accordance with the size of solder to be applied, and at the same time, an image processing module for judging foreign material and a glue bonding condition necessary for strengthening the mounting of components are inspected as options.

Why is solder paste inspection (SPI) required?

Answer: Because 70% of defects occurred immediately after printing.

In recent years, there has been a growing need for smaller, thinner, and lighter PCBs. In an era when micro-unit ultrafine inspection is essential, we recommend the [3D solder paste inspection machine VP Series] that meets such needs and solves problems by placing a dedicated inspection device immediately after a solder printing machine.

3 Reasons

to Recommend CKD’s 3D Solder Paste Inspection Machine

Multi-function inspection

as high speed processing

of solder and foreign material inspectionHigh precision capture by

Ring Lights and 3D ProjectorProprietary development

of diffused LED light

considered solder particles

Functions

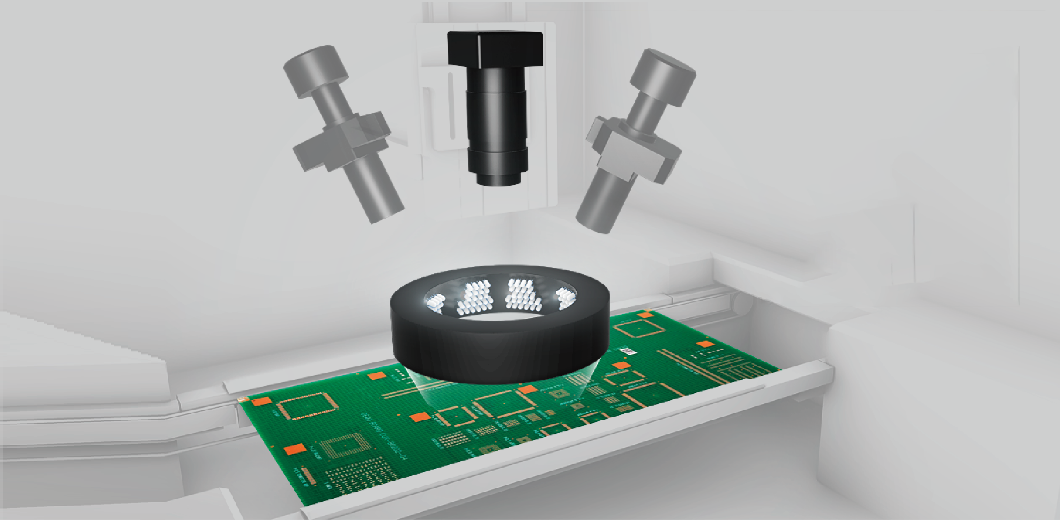

Ring light (Omnidirectional)

A ring light developed to illuminate uniform light sources from all directions for imaging. The fine contours of the object to be inspected are measured in microunits.

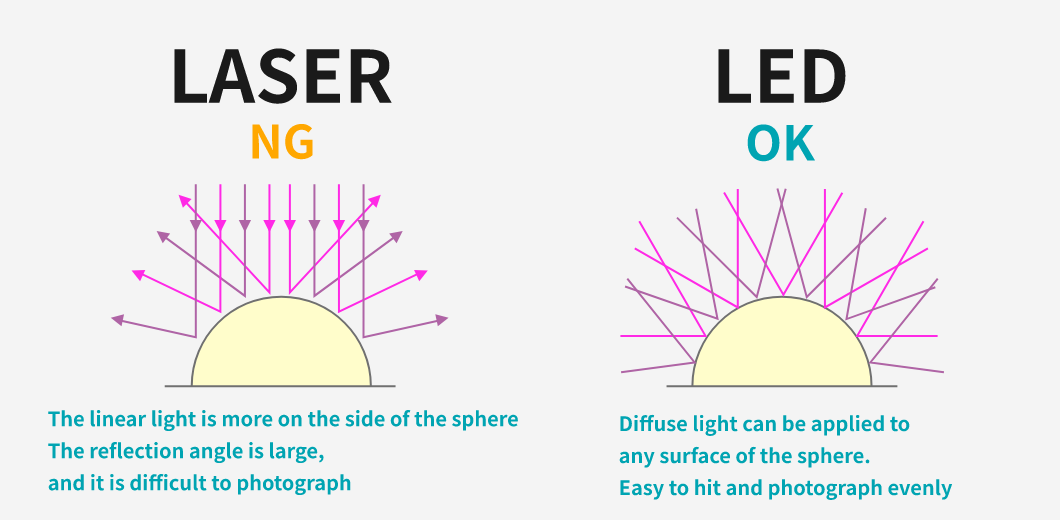

LED diffusion light device dedicated for solder

For fine inspection of a spherical body of solder particles, measurement using diffusion irradiation light is excellent, not linear irradiation light.

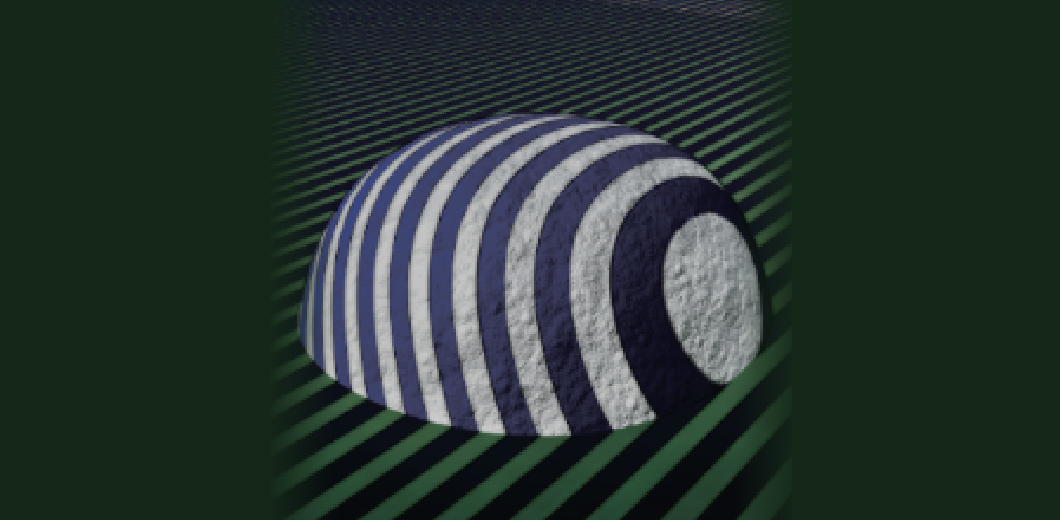

3D Projectors

The 3D projector system is used for volume calculation. The state in which the striped light deviates between the substrate surface and the solder surface is quantified by image processing. You are using a triangulation calculation to find the height.

Z axis Auto-Focus Function

To inspect multilayer substrates for each reflow, CKD’s solder print inspection machine is an SPI inspection machine and can also handle AOI’s warpage inspection.

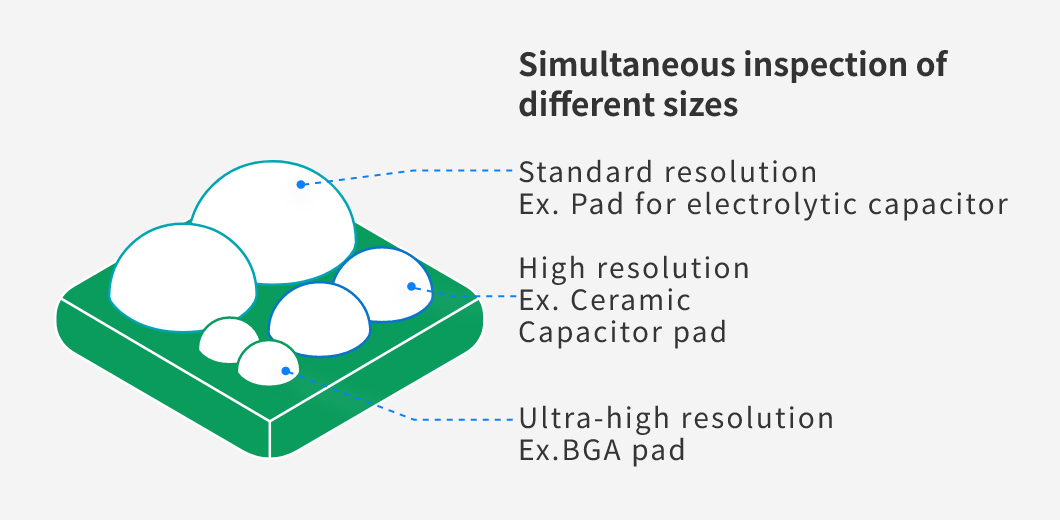

Simultaneous inspection with three different resolutions

Since the electronic circuit board has different capacities of solder, three resolutions are available to suit the needs of each board. Switch quickly for inspection. Compared with the conventional inspection (made by other companies) which only has fine resolution, the inspection speed is extremely different.

Foreign matter inspection is also performed without time loss

In addition, it enables both solder inspection and time-saving foreign material inspection. For foreign material inspection, CKD’s proprietary image processing technology is used, enabling high-precision defect detection.

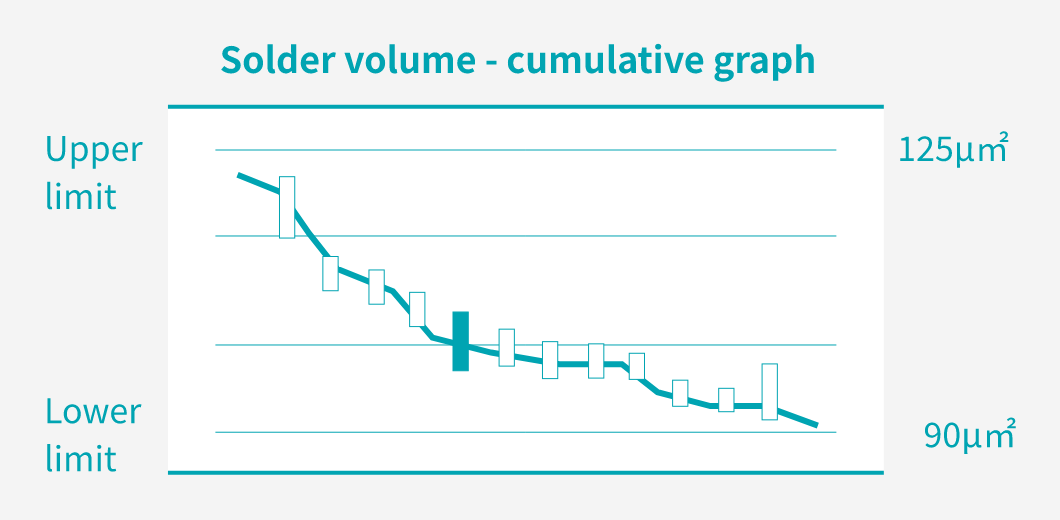

SPC function for stable operation

The threshold value of production result is measured in real time and visualized with a graph (SPC function). Thus, mask replacement during operation, etc., is performed. You can also determine when to restore by age.

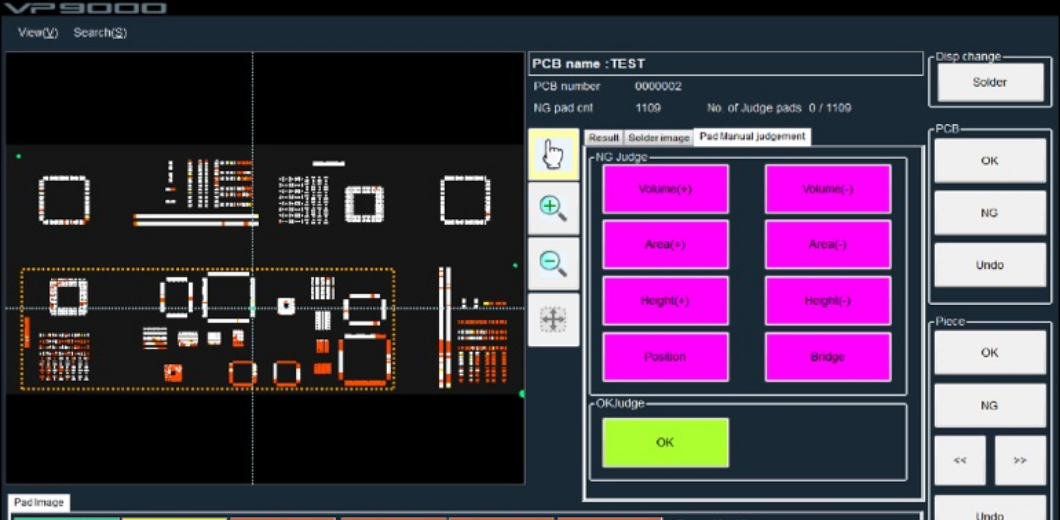

Enhanced judgment function for optimal operation

This product provides the ability to collect information by specifying multiple reasons for success/failure judgment in advance in order to evaluate whether the production plan after introduction is performing optimally over the medium to long term. ※Only for Single lane machine of VP9000

Glue Inspection [Optional]

![Glue Inspection [Optional]](https://www.ckd.co.jp/auto/wp-content/uploads/2024/11/VP-Series_i10_en.png)

Precise amounts of dispensed glue can be measured in 3D for judgement.

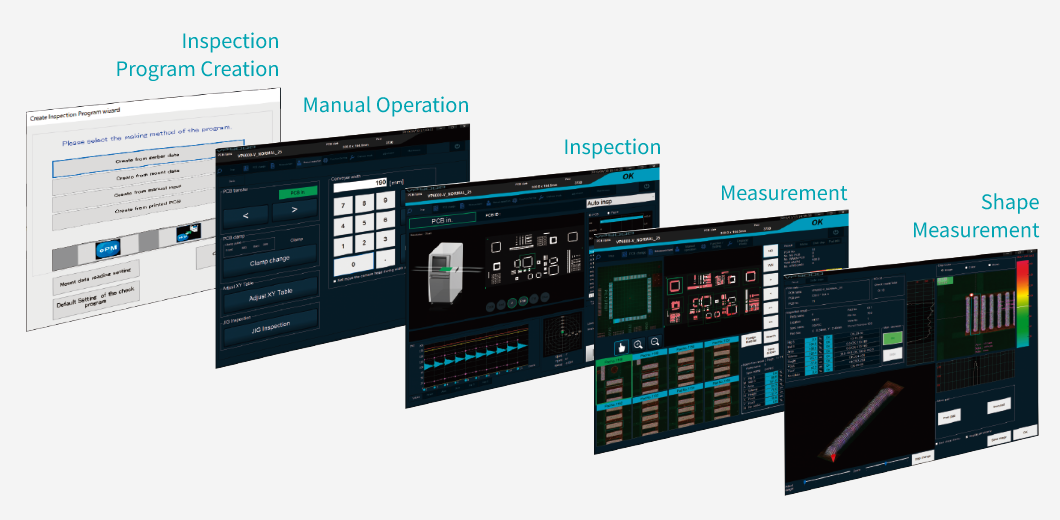

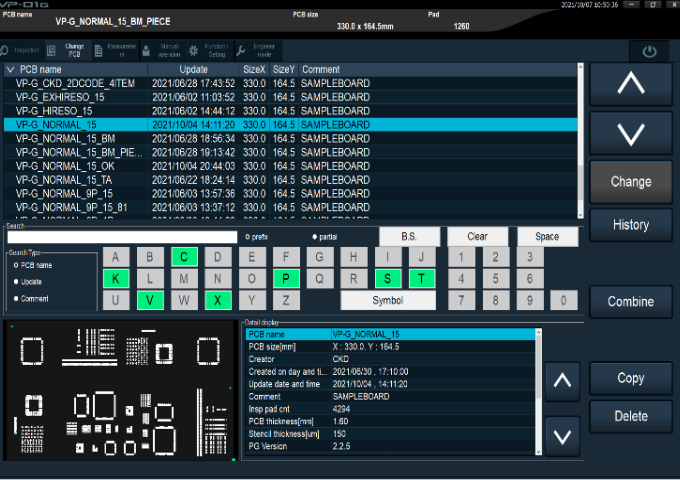

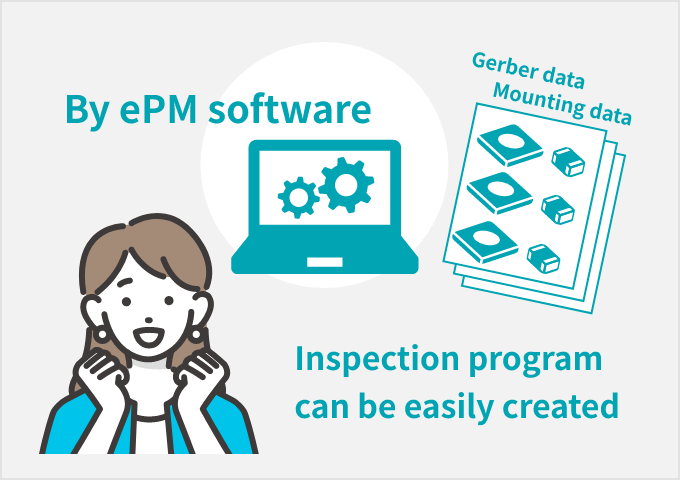

Swift Creation of Inspection Program

Inspection program can be created from Gerber data in minimum of 3 minutes. Part information is easily registered by using mount data and optional software.

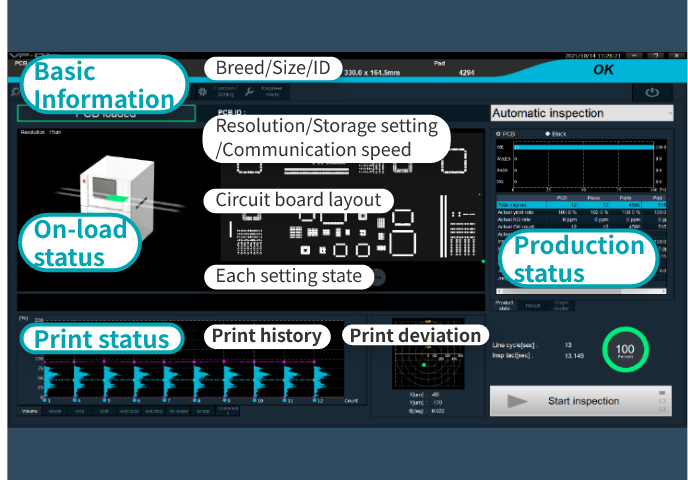

User-friendly GUI

It’s not just rational. Beautiful and easy-to-use operation screen and housing design that takes into account the burden of assembly practitioners.

- Dashboard configuration

- The main setting screen can be viewed on the main screen. 1D/2D code reading, substrate warp following, inspection resolution, etc.

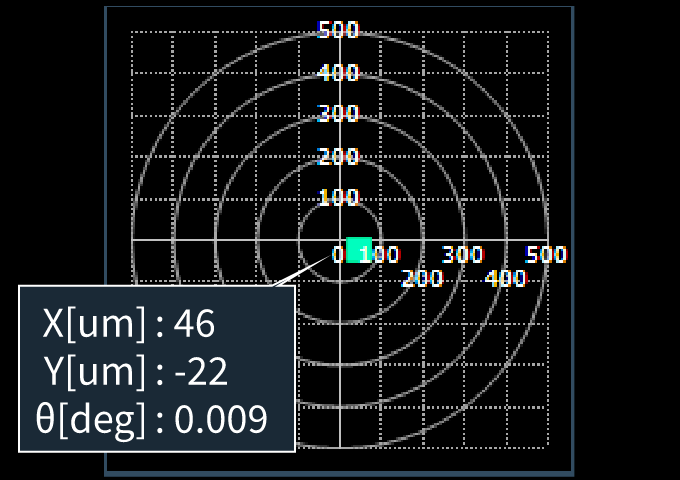

- Visualization of print deviation

- You can see it at a glance with the scatter chart.

- Visualization of production status

- [Judgment result]or [Direct rate]View key information about and confirm operation at a glance.

- Touch monitor angle can be adjusted

- The touch monitor with angle adjustment function allows adjustments of 10 degrees upward and 25 degrees downward.

- Improved keyboard-less operability

- All keyboard-less operation is possible at the optimal position to suit the user’s eyes.

PCBs requiring downsizing, thinning, and weight reduction

Supports double-sided/multi-layered/buildup boards. “Supports all colors”

- Rigid base

- Supports hard insulator base such as glass epoxy and paper epoxy.

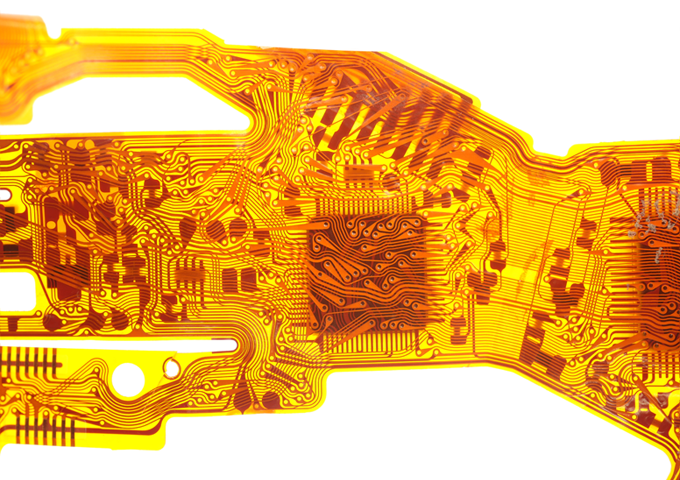

- Flexible board

- Compatible with smartphones and other substrates that require a thin/lightweight body.

- Jig transfer board

- Even for PCBs whose transport reference surface changes due to jigs, solder inspection is accurately performed with the “tray PCB mode”.

- Cavity board

- We also use our unique inspection know-how to handle boards whose reference height changes due to a level difference inside the board.

- Double-sided board

- The Z-axis correction function enables accurate inspection of the solder used for printing on the back side after reflow, where the board tends to warp.

- Boards of various colors

- 3D solder paste inspection Utilizing 30 years of experience, it is equipped with inspection functions that support various substrate colors.

| Standard Machine | High Speed Machine | ||||||

|---|---|---|---|---|---|---|---|

| Inspection Method | Phase Shift Method | ||||||

| PCB Size | 50mm×50mm~510mm×330mm | ||||||

| PCB Thickness | 0.3mm to 5.0mm (max. 3kg) | ||||||

| Projection | Dual Projectors | Single Projector | |||||

| Inspection Resolution (μm) |

Digital Switching Method (3 stages) | ||||||

| 25/12.5/8.5 | 20/10/7 | 15/7.5/5 | 25/12.5/8.5 | 20/10/7 | 15/7.5/5 | ||

| Inspection Speed (mm²/sec) |

Standard | 8900 | 5600 | 1900 | 9400 | 6000 | 2000 |

| High Resolution |

5700 | 3500 | 1200 | 6000 | 3700 | 1300 | |

| Super High Resolution |

3200 | 1900 | 650 | 3300 | 2000 | 700 | |

| PCB Warping Compensation |

max.5mm | ||||||

| Utilities | Power Supply: Single Phase AC200V to 240V 50/60Hz MAX 1KVA Air: 0.3MPa to 0.4MPa 2.0NL/min Hose Diameter ø 8 mm | ||||||

| VP-01G | |||||

|---|---|---|---|---|---|

| Basic Specification |

Dimensions (W x D x H) |

938 x 1,191 x 1,480mm | |||

| Conveyor Height | 900±20mm | ||||

| PCB Size | 50×50 mm – 510×510mm (L size) | ||||

| Min. PCB Edge Clearance | 4mm | ||||

| PCB Clearance (Top/Bottom) |

Top 5mm, Bottom 30mm | ||||

| PCB Thickness | 0.3 – 5.0mm | ||||

| PCB Weight | Less than 5kg | ||||

| Machine Weight | 600kg | ||||

| Power Supply | Single phase AC200V – 240V ±10% 50/60Hz ±1Hz | ||||

| Power consumption | Max. 1KVA | ||||

| Pneumatic Supply | 0.3 – 0.4MPa (4kgf/cm²) | ||||

| VP Inspection Technology |

Camera | CMOS Mono Camera – Global shutter spec.- | |||

| Inspection Principle | Phase Shift + Hybrid Inspection – 2D Ring light and 3D Projector(s) | ||||

| Inspection Item | Volume, Projection, Dimness, Area, Shift, Average Height, Bridging, No Solder, Coplanarity, Foreign Material, Glue (Option) | ||||

| Mechanical Technology |

Clamping Method | Side, Top and Bottom Simultaneous Clamping | |||

| PCB Stop | Sensor Control System (No Stopper) | ||||

| PCB Load/Transfer | Double Side PCB Loading/Transfer System | ||||

| PCB Warpage | ±5mm (Original Mechanical Adjustment System) | ||||

| Performance | Inspection Resolution (Multiple Resolution Switch Function) |

25/12.5/8.5μm | 20/10/7μm | 15/7.5/5μm | 10/5μm |

| Solder Paste Height (Standard) |

Less than 400μm | Less than 300μm | Less than 300μm | Less than 150μm | |

| Solder Paste Height (Option) |

Less than 600μm | Less than 450μm | Less than 450μm | Less than 225μm | |

| Max. Inspection Speed | 9400 | 6000 | 3300 | 1400 | |

| FOV Size | 50×50 | 40×40 | 30×30 | 20×20 | |

| Min. Solder Paste Pitch | 50μm (Stencil thickness: 100um) | ||||

| Height Resolution | 1μm | ||||

| Accuracy (3σ) | Within 2% (Dual Projection)/Within 3% (Single Projection) | ||||

| GR & R | Within 10% | ||||

| Software | Inspection Program | CKD VPDS Programing System (Program Creation Time Min. 3 mins) ePM Programing Software (Option) | |||

| SPC | CKD Realdata Software System (Real Time Histogram, X bar & R Chart, CP/CPK Chart, Real Time SPC, SPC Alarm, SPC Report) | ||||

| Optional | Closed Loop ePM Auto Program Launch Area Standard Jig Height Standard Jig ITAC Q-up Opti Dual Projection CE Compliance |

||||

| Model | VP9000 (Standard Machine) | VP9000 (High-speed Machine) | |||||

|---|---|---|---|---|---|---|---|

| Inspection Method | Phase Shift Method | ||||||

| PCB Size | (M) 50x50mm~330x250mm (L)50x50mm~510x460mm |

||||||

| PCB Thickness | 0.3~5.0mm | ||||||

| Projection | Dual Projectors | Single Projector | |||||

| Inspection Resolution | Digital Switching Method | ||||||

| 25/12.5/8.5μm | 20/10/7μm | 15/7.5/5μm | 25/12.5/8.5μm | 20/10/7μm | 15/7.5/5μm | ||

| Inspection Speed (mm²/sec) |

Standard | 8900 | 5700 | 3200 | 9400 | 6000 | 3300 |

| High Resolution |

5600 | 3500 | 1900 | 6000 | 3700 | 2000 | |

| Super High Resolution |

1900 | 1200 | 650 | 2000 | 1300 | 700 | |

| Accuracy (volume 3σ) *1 |

Within 2% | Within 3% | |||||

| PCB Warping Compensation |

±5mm | ||||||

| Outline Dimensions | (M)724x970x1500mm (L)904x1180x1600mm |

||||||

| Power Supply | Single Phase AC200~230V 50~60HZ MAX 1KVA | ||||||

| Pneumatic Supply | Not Required | ||||||

| Weight | (M)460kg (L)550kg |

||||||

| UPS | Standard Equipment (only PC) | ||||||

| Environmental Standard | RoHS | ||||||

| *1 When CKD sample board is used. | |||||||

| Optional | ・Data Station (connect up to 6 sets of machines) ・Loading Conveyor ・Unloading Conveyor ・Glue Inspection ・Transformer ・1D & 2D Code Reading ・Mount Data Conversion Software ・ePM-SPI Software ・Keyboard Tray ・CE Compliance (Large machines only) ・Feedback/Feedforward ・Ultrafine Resolution (10, 8, 5μm) |

||||||

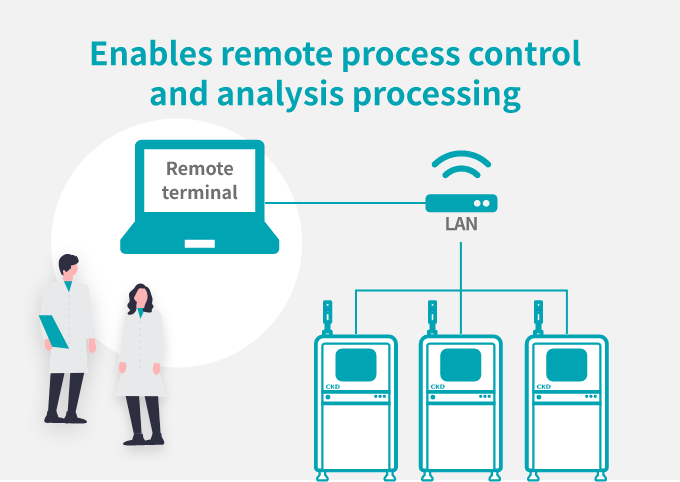

- Data Station VPDS

- Data creation/editing can be done remotely during operation. In addition, all inspection results and images can be collected in real time, enabling remote monitoring and statistical analysis.

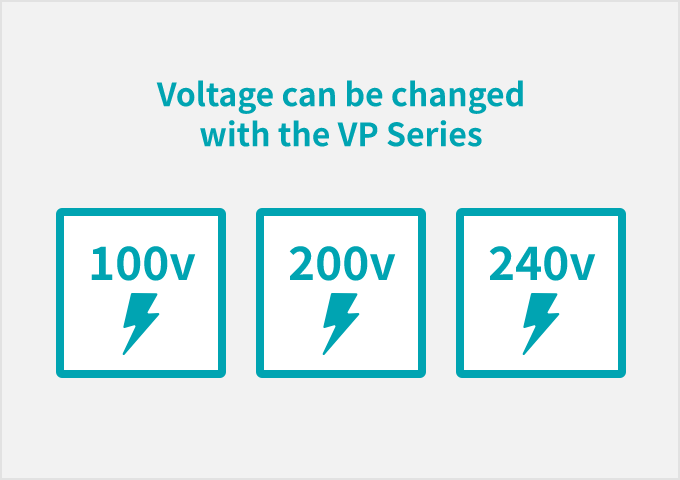

- Power supply voltage change

- The primary power supply voltage can be changed to AC240V or AC100V to suit the voltage specifications of various parts of the world.

- ePM software

- Compatible with other equipment, including overseas, ePM software is also available, allowing easy creation of inspection programs from CAD data.

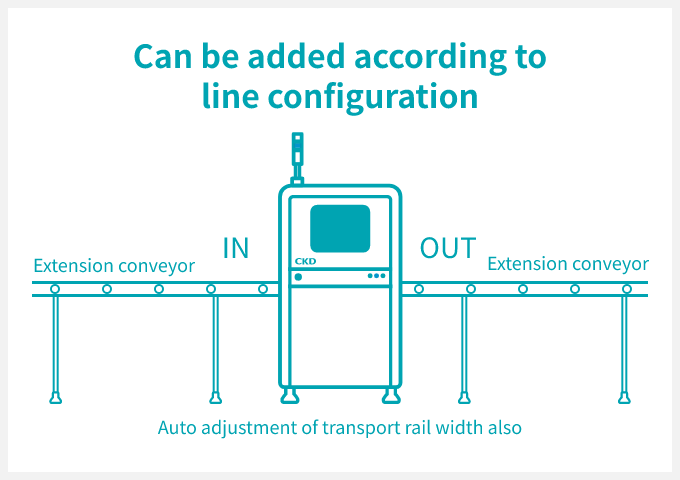

- Loading/Unloading conveyor

- Depending on customer’s preferences and configuration of production line, CKD extension conveyors can be added to each side of PCB loading or unloading.

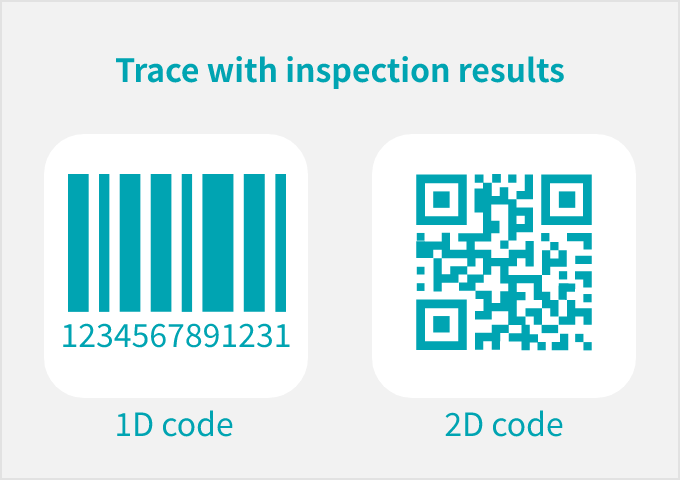

- 1D/2D code reading function

- Using inspection camera, read various 1D/2D codes on PCB. The read information can be added to inspection result data, and traced.

- CE compatible (L machine only)

- Complies with the European CE standards, which have been officially approved by a third-party organization.

- Mounting data conversion software

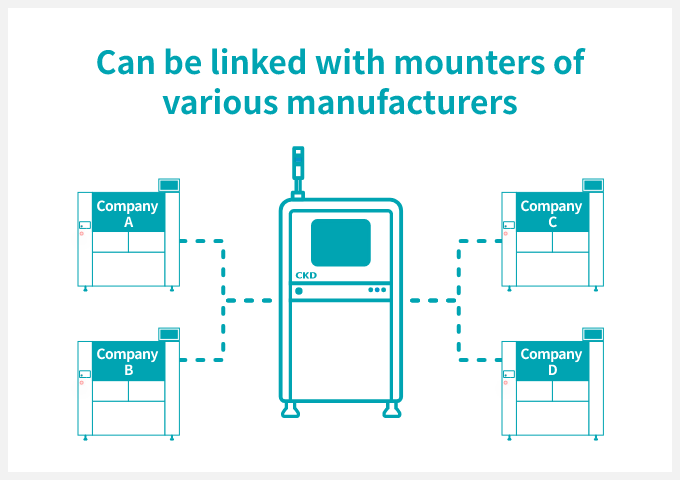

- It follows each format of various mounters, converts mounting data, and makes it easy to register various parts and perform printing condition analysis for each part.

- Super-fine resolution compatible

- To support even the smallest parts that are not mounted in normal SMT process, “10 μm, 8 μm, and 5 μm” are available in addition to the standard lineup.

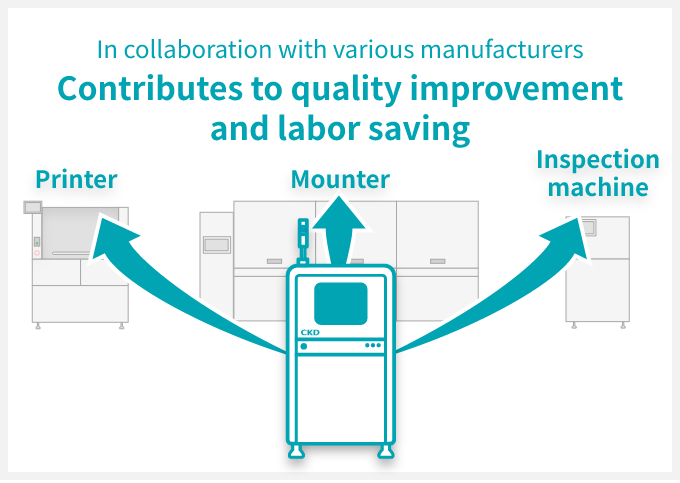

- Pre- and post-process linkage function

- Coordination between processes is possible with printers, mounters, and inspection machines from various manufacturers. Contributes to automatic quality improvement and labor saving of SMT lines.

-

- Inspection Machine

- Inspection for Printed Circuit Board

Solder Paste Inspection Machine

Click here for details

VP Series