Turns heavy labor into light work!

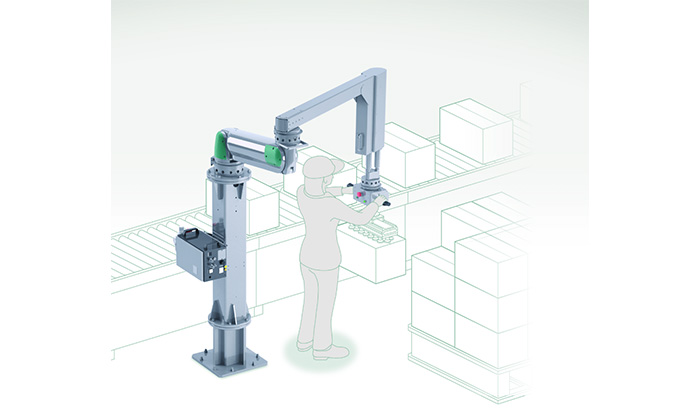

PowerArm Series of assistive devices

Pneumatically assists motion from the side or from below.

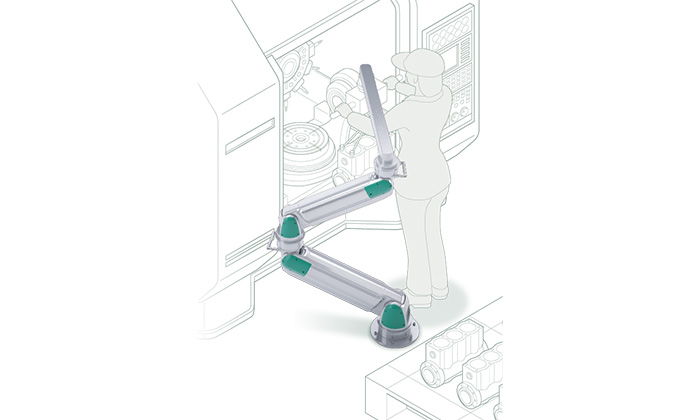

It can comfortably carry heavy objects even in narrow places such as inside machine tools.

If you have this problem

-

- Problem 01

- Reduce the load on the body when replacing jigs and workpieces on machine tools!

-

- Problem 02

- When using assistive devices even in places where space is limited!

-

- Problem 03

- When considering the ideal transport method for each workpiece!

The PowerArm Assistive Device

What is the PowerArm Assistive Device?

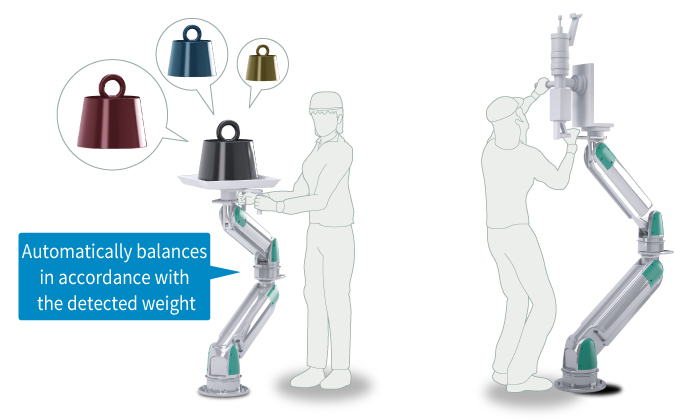

It is a new type of balancer (weight assisting component) that assists motion from the side or from below using compressed air. Automatically balances according to the detected weight.

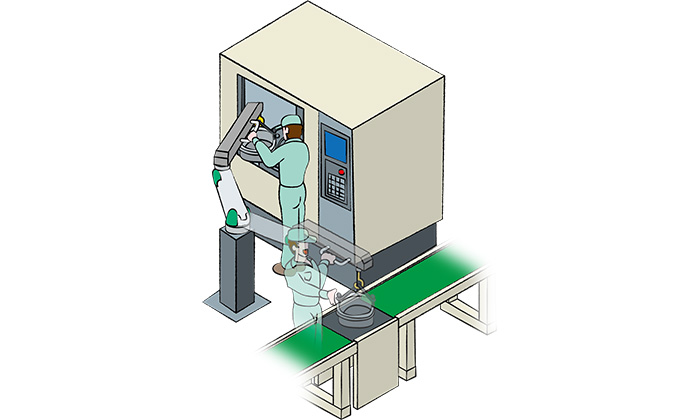

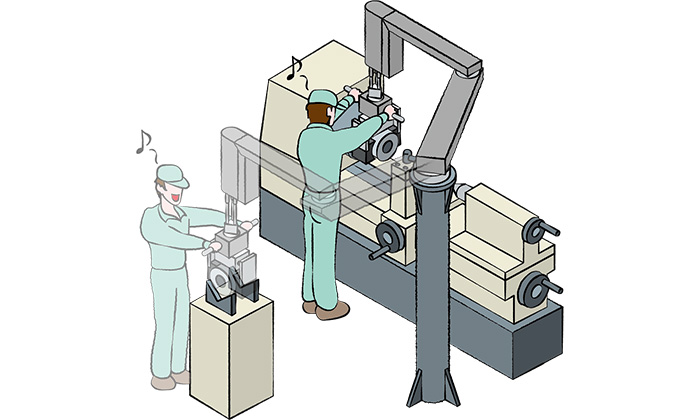

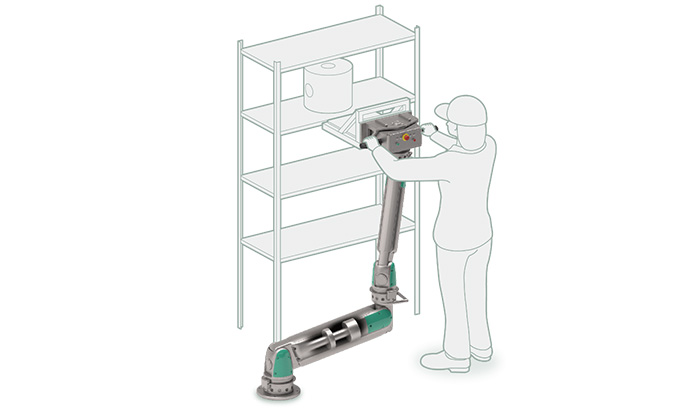

For changing workpieces and jigs on machine tools

Machine tools have ceilings, making it difficult to use assistive devices from above. However, the PowerArm assists motion from below, making it easy to replace workpieces and jigs inside machine tools.

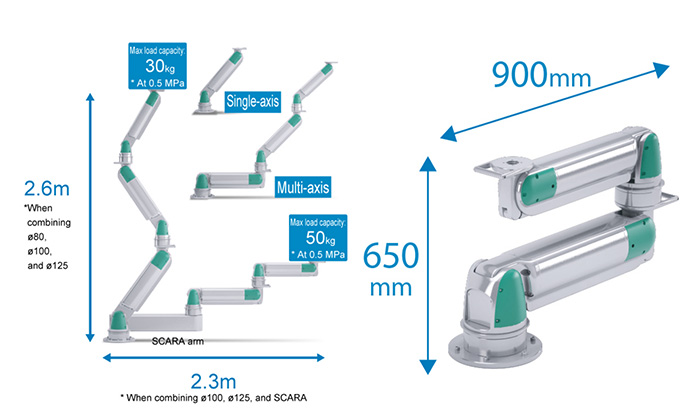

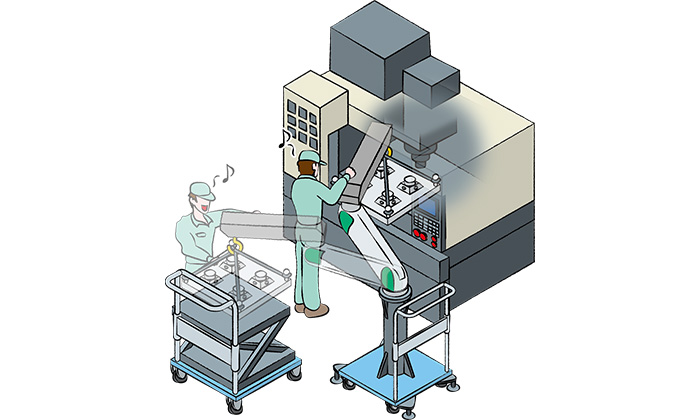

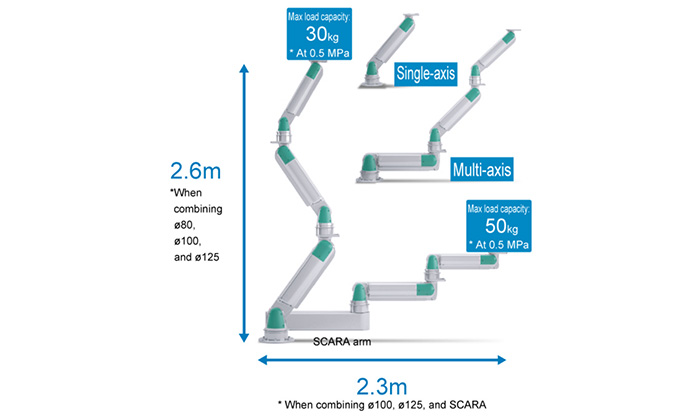

Range of Motion and Stowability

It supports a wide range of movement, up to 2.6m long and 2.3m horizontal. It can be compactly stored within 1 m square when not in use.

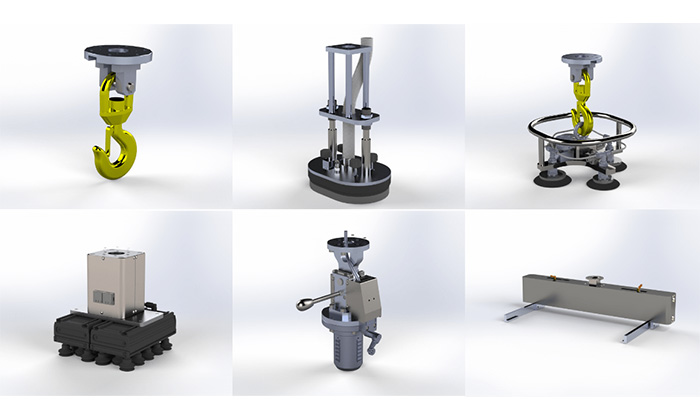

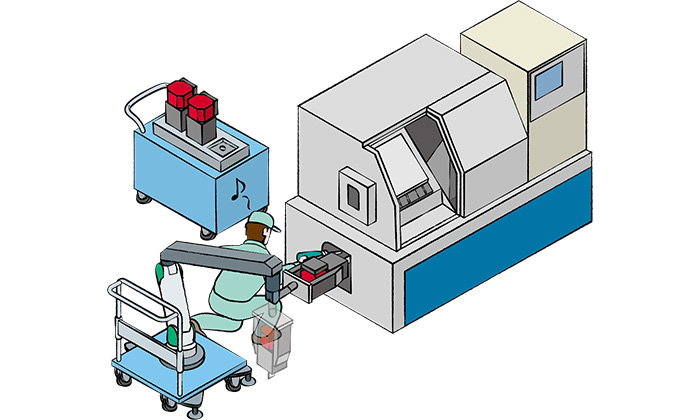

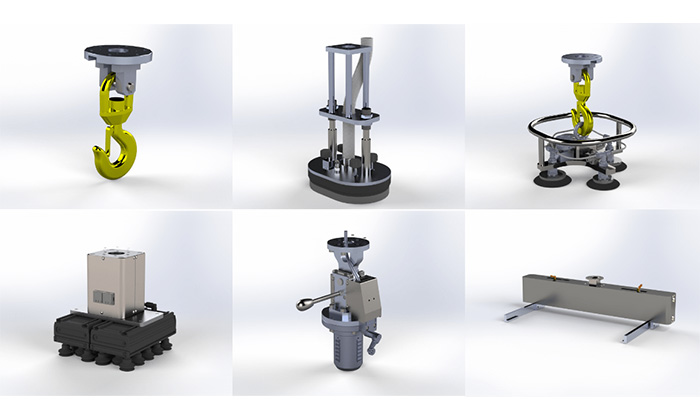

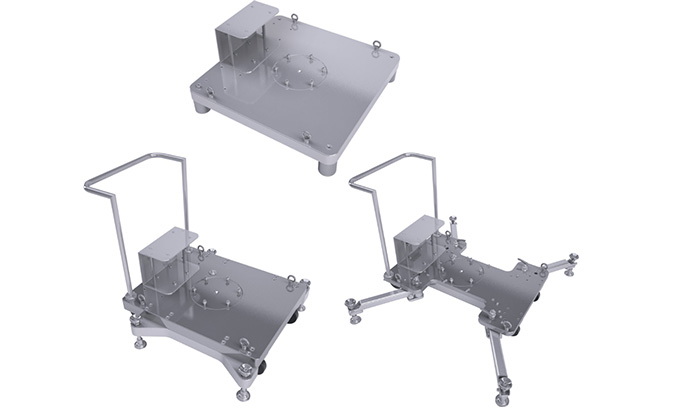

Controls and attachments tailored to the workpiece

Attachments and control can be made according to the workpiece. Dollies and control boxes, etc., can be prepared according to your work and workpieces.

For more details

Video content

-

PowerArm Assistive Device

Frequently Asked Questions

-

Is it possible to get a tour or demonstration?

Yes, it is. Please contact us for details. -

What is the estimated cost of the PowerArm.

It depends on the specifications, and so please contact us using the inquiry form. We will contact you with a rough estimate of the cost after proposing the most suitable specifications for you. -

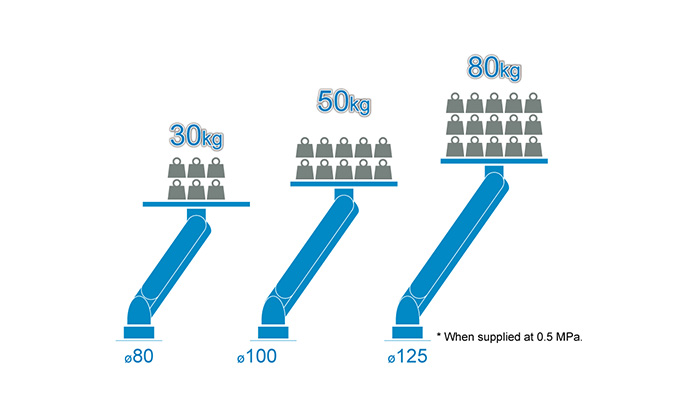

What is the maximum transfer weight?

The workpiece weight can be up to about 80 kg, but it depends on the specifications and attachments. -

How long is the delivery time?

Normally, about 2 months. However, it depends on the specifications, so please contact us.

For solving the following problems with machine tools

Setting the workpiece on the Machine Tool

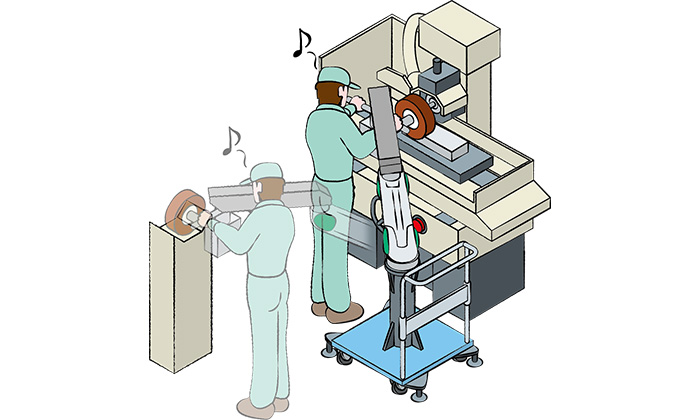

Even in cases where there is a ceiling that prevents the use of an assist device or other device from the top, the PowerArm can approach from the side, reducing the need to work in an unreasonable position. Pipe-shaped workpieces can be safely transported by clamping with an air hand.

Setting Pipe-shaped Workpieces on the Washer

Pipe-shaped workpieces can be safely transported by clamping with an air hand.

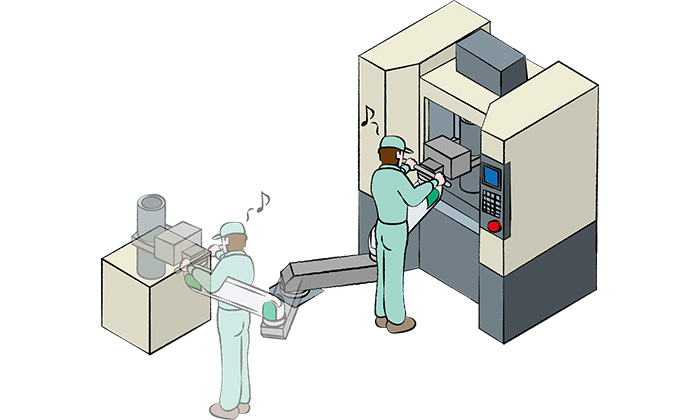

Changing jig setups on a vertical machining center

Jig replacement, which was done with two workers, can now be done by one person, contributing to labor saving.

Setting a round bar-shaped workpiece on a lathe

Round bar-shaped workpieces are difficult to grip, and there is a risk of injury if they are accidentally dropped, the PowerArm enables safe workpiece settings.

Attaching and detaching grinding wheels to and from grinding machines

Enables work with an unreasonable posture to be performed in a safe position, thereby preventing back pain. Also, a dolly can be used for conveyance between processes.

Assembly assistance for machine tools

Working with a hoist can be difficult to move smoothly, but the PowerArm can be clamped directly with a dedicated attachment, helping to reduce work time.

CONTACT

×

×

Turns heavy labor into light work!

×

PowerArm Assistive Device