Eliminates concerns of contamination in food manufacturing processes

Components for Food manufacturing processes

You cannot go wrong with this choice! A broad lineup for food manufacturing processes.

If you have this problem

-

- Problem 01

- Needs to be used for food manufacturing processes!

-

- Problem 02

- What components need to be choosen?

-

- Problem 03

- We want to perform sanitation management in accordance with HACCP, FSSC 22000, and the Food Sanitation Act!

To solve the problems

Food grade for safety and security is available

● FP1 using food grade lubricant (NSF H1) to eliminate concerns of contamination

● In addition to FP1, FP2 uses resin and rubber materials compliant with the Food Sanitation Act

● In addition to FP2, FP3 takes into account lubrication, materials, and structure

● In addition to FP1, FP2 uses resin and rubber materials compliant with the Food Sanitation Act

● In addition to FP2, FP3 takes into account lubrication, materials, and structure

Easy to find, easy to select, easy to use

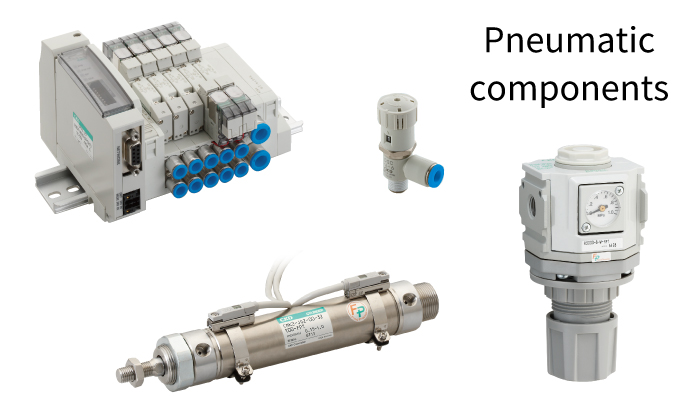

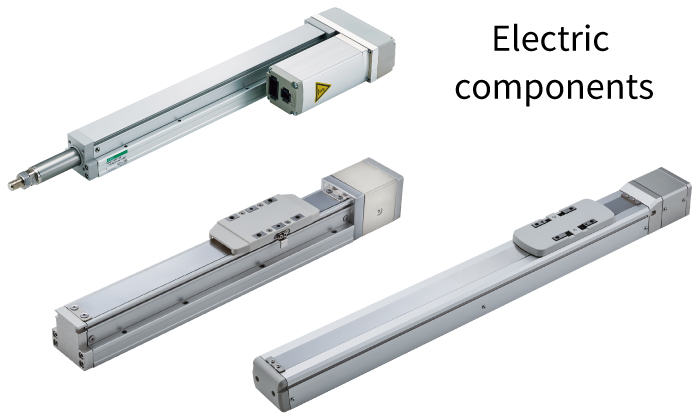

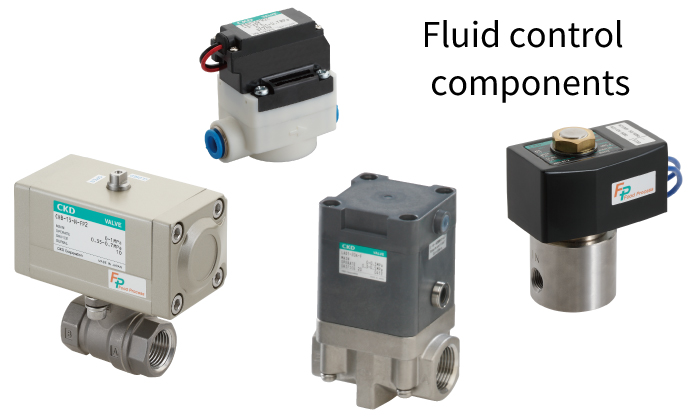

●A broad lineup of components used in food manufacturing devices from air filters to actuators are available.

●Blue fittings and FP logo stickers are affixed to the products so that they can be easily identified for food manufacturing.

●Blue fittings and FP logo stickers are affixed to the products so that they can be easily identified for food manufacturing.

Contributes to HACCP implementation and FSSC22000 Certification

●Recommend use of FP Series for food safety and assurance

●This logo represents our commitment to support food manufacturing processes with safe CKD products.

●This logo represents our commitment to support food manufacturing processes with safe CKD products.

Compliant with the Food Sanitation Act / Positive List System

● Resin parts used in flow paths that come into direct contact with food, mainly in fluid control valves, etc., are compliant with the Positive List System.

* Products compliant with the Positive List are indicated with a "PL" icon in the catalog (Compliant with MHLW Notification No. 196, 2020).

● Contributes to improving food safety.

* Products compliant with the Positive List are indicated with a "PL" icon in the catalog (Compliant with MHLW Notification No. 196, 2020).

● Contributes to improving food safety.

For more details

Video content

-

Components for Food manufacturing processes FP Series -

Introduction of FP Series products for food manufacturing processes

Frequently Asked Questions

-

How to get started with adopting HACCP?

To contribute to the implementation of HACCP and FSSC22000 Certification, the FP Series is available for proposing appropriate equipment. -

How can the standard products be distinguished from products for food production?

The FP logo seal is attached to the product so that you can see at a glance the difference from standard products, and FP1 or FP2 is indicated at the end of the model No. In addition, for products with fittings, the push ring is blue in color. -

How long will the delivery take?

Most products have standard delivery +3 days. -

What kind of system is the Positive List?

The Positive List System is a regulatory framework that, in principle, prohibits the use of any substances other than those published in a "list of approved substances (Positive List)." Previously, Japan used a "Negative List System" that only restricted problematic substances, but revisions to the Food Sanitation Act now require more stringent management. From June 2025, it will be prohibited to manufacture or sell apparatus, containers, and packaging made of synthetic resin that come into direct contact with food unless it can be proven that the materials used are on the Positive List. Additionally, components within equipment that come into contact with food are also subject to this regulation.

CONTACT

×

×

Eliminates concerns of contamination in food manufacturing processes

×

Components for Food manufacturing processes FP Series

Introduction of FP Series products for food manufacturing processes