Case Studies

Quality assurance for the miniaturization era

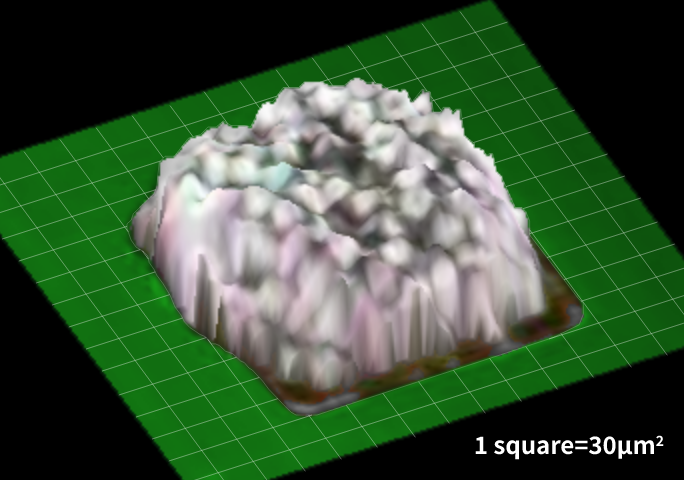

3D solder paste inspection of BGA pad

- Industry/Business Type

- Electronic devices and components, electronic device manufacturers and contract manufacturing services (EMS)

- Installed product

- VP9000

- Related Tags

- 3D solder paste inspection machine / BGA inspection / multi-resolution switching function

Contact details / CKD Automatic Machinery

- This case study introduces an example of how our customers who were having problems were able to feel the benefits of introducing our products, which led to improvement of the product quality and production efficiency of our customers.

Mr. Takayuki Harada, Marketing Dept. Gr.1, Machinery Sales Dept., Automatic Machinery Business Division

Customer Challenges

Protecting Invisible Quality: Overcoming the Challenges of Miniaturization Components and BGA Inspection

Board mounting manufacturers, who had relied on conventional automatic visual inspection (AOI), were challenged with miniaturization of parts and quality assurance of BGA (Ball Grid Array). A new inspection method was needed to ensure the quality of BGAs, which are difficult to visually inspect, and for which solder joints cannot be seen after mounting.

Effects of Deploying VP9000

With the introduction of VP9000, it was possible to control the mounting quality of fine parts and BGAs from the solder printing process, which was difficult after the component mounting process, leading to improved quality control and lowering the defect rate of BGAs. In addition, the multi-resolution switching function enables high-speed and high-precision solder inspection of the entire circuit board, enabling smooth in-line inspection. As a result, the efficiency of the entire manufacturing process is improved, contributing to the improvement of product quality.

1.BGA Quality assurance

With the introduction of VP9000, it is now possible to inspect all-number, three-dimensional fine solder pads prior to BGA mounting. This ensures the quality of the BGA.

2. Achieving high-precision inspection

By making use of the “multi-resolution switching function”, one of the biggest features of VP9000, it has become possible to inspect fine pads for BGAs with high accuracy and accuracy. This has dramatically improved the quality control of fine parts.

3. Gain an efficient inline inspection system

Solder inspection of the entire circuit board is possible at a high speed, enabling smooth in-line quality control. This improves the efficiency of the entire manufacturing process.

Features Introduced in Case Studies

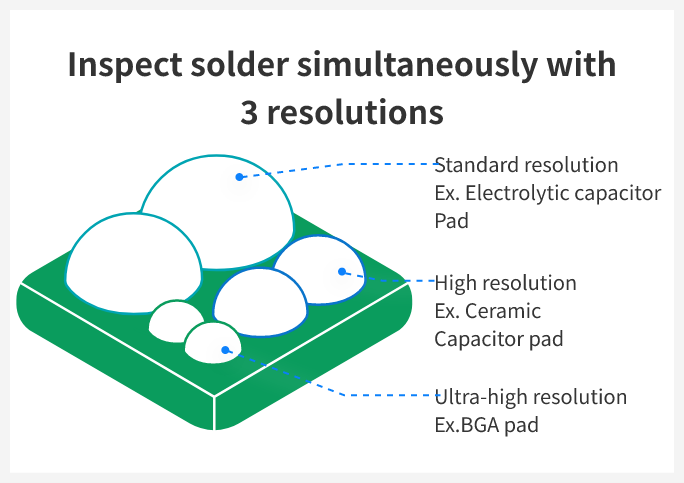

Multi-resolution switching functionCompared with the conventional inspection (made by other companies) which only has fine resolution, the inspection speed is extremely different.

Z-axis compensation functionTo inspect multilayer substrates for each reflow, CKD’s solder print inspection machine is an SPI inspection machine and can also handle AOI’s warpage inspection.

Measuring to the grounding surface of solder and circuit boardSolder in low-altitude areas close to the ground surface can be accurately measured with the VP Series.