Case Studies

Tens of thousands of pads inspected successfully

VP Adoption for End-User Confidence

- Industry/Business Type

- Electronic device contract manufacturing service (EMS)

- Installed product

- VP9000

- Related Tags

- 3D solder paste inspection machine/ultra-fine resolution compatible/high speed multi-pad processing

Contact details / CKD Automatic Machinery

- Here are some examples of how CKD’s long experience has helped us solve your problems concretely with the specs that we already have. This case led to the success of stable quality after introduction, and the above-mentioned European customers now use about 30 of our inspection machines.

Affiliation: Genta Shibasaki, Sales Dept., Industrial Machinery Sales Dept., Automatic Machinery Business Division

Customer Challenges

Beyond the limits of existing inspection machines: Inspection innovation of tens of thousands of pad boards

In the inspection of boards on which tens of thousands of pads of solder paste are printed, the processing capacity of solder paste inspection machines manufactured by other companies was insufficient, and the inspection required a significant amount of time.

Effects of Deploying VP9000

With the introduction of VP9000, it is possible to perform board inspection of tens of thousands of pads without problems, which could not be done with inspection machines of other manufacturers. This has allowed us to receive work from end-users, which has expanded our customer’s business opportunities. In addition, the full-image storage function has enabled the end-user to receive the results of the inspection, thereby increasing reliability and peace of mind. The high processing power and value-added features of VP9000 have enabled inspection process efficiency and quality improvement.

1. Full pad inspection is possible with high processing performance

With the introduction of VP9000, even tens of thousands of pads of boards can be inspected without problems. This enables accurate inspection of each pad on the circuit board and significantly improves the defect detection rate. In addition, the high-speed processing capacity reduces inspection time and improves production efficiency.

2. Increased orders received

The high-performance inspection capability allows customers to reliably receive work from end-users. The introduction of VP9000 has increased reliability and the reputation of end users. As a result, there are more ongoing orders received from end-users and new business opportunities.

3. Peace of mind through full image storage

With the full-image storage function, traceability of inspection data is ensured, enabling rapid response when problems occur. In addition, we improved transparency for end-users, which also led to a stronger relationship of trust.

Features Introduced in Case Studies

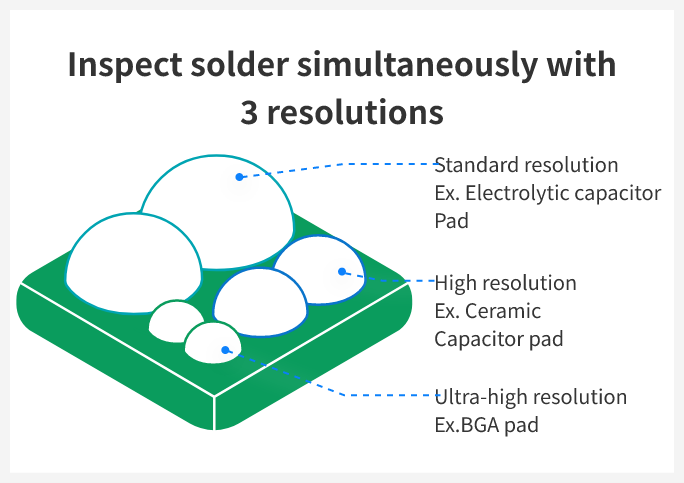

Multi-resolution switching functionCompared with the conventional inspection (made by other companies) which only has fine resolution, the inspection speed is extremely different.

Ultra-fine resolution compatibleTo support even the smallest parts that are not available with normal SMT, “10 μm, 8 μm, and 5 μm” are available in addition to the standard lineup.

Improved printing conditionsYou can divide them into any group and compare printing trends. It is ideal for comparison between different printing conditions and for comparison between pre- and post-cleaning printing conditions.