Improved air blowing leads to energy savings throughout the factory!

Proposal to improve air blowing

In factories, a lot of compressed air is used for air blowing, such as for draining, removing chips and dust, transporting, and sorting. Improving this air blowing process leads to energy savings for the entire factory.

If you have this problem

-

- Problem 01

- Reduce overall plant power consumption

-

- Problem 02

- Reduce air consumption

How to solve the issues

Improved solenoid valve that supplies compressed air

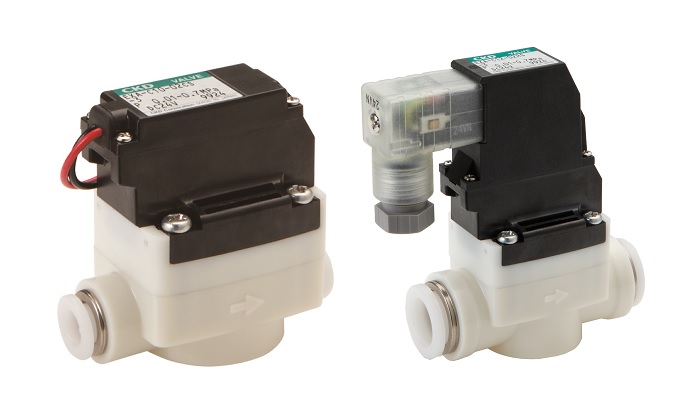

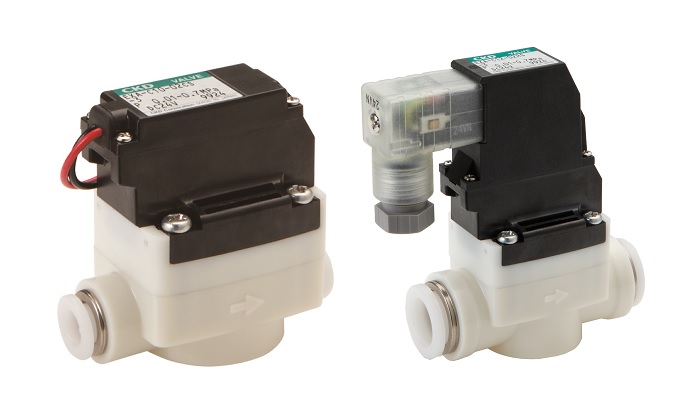

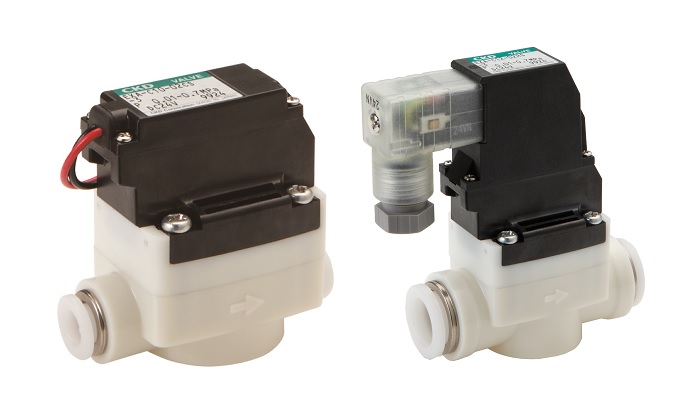

Pilot operated 2-port solenoid compact air blow valve for compressed air EXA Series

● Employs a pilot actuator with a low power consumption (0.6 W) 3-way valve, enabling large flow rates and low power consumption

● Component port size can be downsized

● Employs a pilot actuator with a low power consumption (0.6 W) 3-way valve, enabling large flow rates and low power consumption

● Component port size can be downsized

Improved blow nozzle

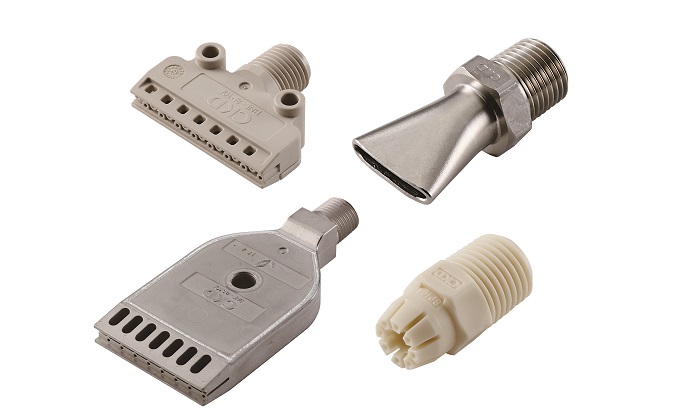

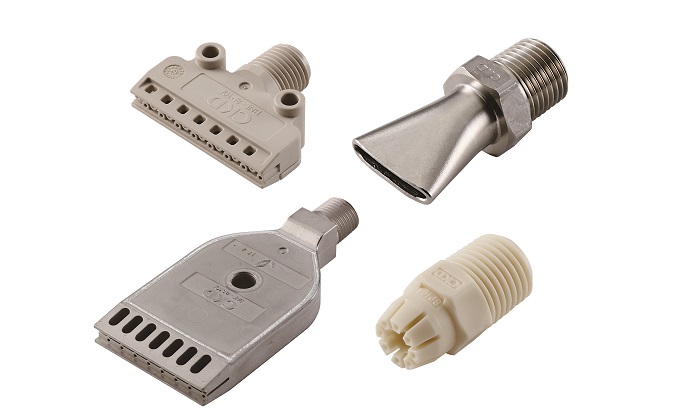

Air blow nozzle BN* Series

●Employs a special structure that brings in surrounding air to enhance the air source, resulting in a powerful jet with low air consumption

● Phase structure of upper and lower jets and air suction holes enables uniform air jetting to the targeted area

● Highly efficient air blow with minimal reduction in impact force due to distance

●Employs a special structure that brings in surrounding air to enhance the air source, resulting in a powerful jet with low air consumption

● Phase structure of upper and lower jets and air suction holes enables uniform air jetting to the targeted area

● Highly efficient air blow with minimal reduction in impact force due to distance

Air consumption is further reduced by intermittent blowing (pulse blowing)

Pulsed blow valve NP1X/NAP1X Series

● Air consumption is reduced by changing from continuous air blowing to intermittent air blowing.

● Since the force of air blow is the strongest when jetting, air can be always jetted with high force

● As a power supply is not required, it can be used simply by directly mounting it on an existing equipment

● Air consumption is reduced by changing from continuous air blowing to intermittent air blowing.

● Since the force of air blow is the strongest when jetting, air can be always jetted with high force

● As a power supply is not required, it can be used simply by directly mounting it on an existing equipment

CONTACT

×

×

Improved air blowing leads to energy savings throughout the factory!

×