Introduction and Selection of Electric Grippers

In recent years, the demands for workpiece diversification, higher precision, and energy conservation have been increasing. CKD offers a range of electric grippers that address various challenges, such as handling diverse workpieces, providing soft handling, and saving space.

This article provides a comprehensive guide to selecting electric grippers and introduces CKD's product lineup.

- 1.CKD's Electric Grippers

- 2.Basic for Electric Grippers

- 2-1.What is an Electric Gripper? Differences between Electric Hands and Electric Chucks

- 2-2.Advantages of Using Electric Grippers

- 2-3.Applications of Electric Grippers

- 3.How to Select the Electric Gripper

- 4.Type of Electric Gripper and Shape of Attachment

- 5.How to Select the Controller for the Electric Gripper (CKD Product)

- 5-1.Easy setting

- 5-2.Space saving

- 5-3.Compatible with Compatible Models

- 5-4.Selectable Power Supply Method (CKD ECMG Series)

- 5-4-1.Central wiring

- 5-4-2.Mixed wiring method

- 5-4-3.Individual wiring method

- 6.Electric Gripper with Built-in Controller (FFLD Series)

- 7.Air Chuck Option

- 8.CKD’s Features | Track Record of Approximately 1,400 Companies Worldwide

- 9.CKD Product Lineup

- 10.Contact CKD if You Have Problems Using the Electric Gripper

CKD's Electric Grippers

CKD's electric grippers not only replace conventional air hands but also offer the advantages of motorized control, such as adjustable speed and gripping force, enabling flexible handling of diverse workpieces and delicate items.

CKD's electric grippers solve the following customer challenges:

●Building flexible handling systems compatible with diverse workpieces, a task difficult to achieve with air hands and air chucks.

●Streamlining equipment for space and wiring savings.

●Implementing electric grippers optimized for IoT-enabled smart factories.

Basic for Electric Grippers

This section provides an overview of electric grippers, their advantages, and application examples.

What is an Electric Gripper? Differences between Electric Hands and Electric Chucks

Electric grippers are automated devices that use electric power to open and close fingers and grip workpieces.They are widely used for transporting and assembling parts in factory production lines.

The terms "electric hand" and "electric chuck" are sometimes used interchangeably with "electric gripper". While there are subtle nuances between these terms, they are often used synonymously in practice.

Advantages of Using Electric Grippers

Electric grippers offer numerous advantages, contributing to advancements in automated lines. Beyond simple gripping, electric grippers provide versatile functions for more flexible handling:

| Function | Explanation |

| Gripping force control | Grips fragile workpieces with the appropriate force |

| Speed control (soft touch) | Reduces impact and workpiece damage during contact |

| Grip detection (positioning complete output) | Verifies correct workpiece gripping |

| Gripping position control | Enables optimal handling based on workpiece material, shape, and size |

Electric grippers enable high-mix, low-volume production, which was difficult with conventional air hands and air chucks, furthering automation in manufacturing.

Applications of Electric Grippers

Electric grippers can handle various materials, including metal and plastic parts, and even delicate or deformable items like food, pharmaceuticals, and cosmetics.

Adjusting grip force for different workpiece materials was challenging with conventional air hands and air chucks, requiring specialized solutions for fragile items. However, electric grippers allow precise grip force adjustment, enabling gentle handling.

| Process | Applications |

|---|---|

| Transport | Conveying of rubber sheets, rubber parts, etc. |

| Conveying of cosmetic bottles and tubes, etc. | |

| Conveying of pharmaceuticals, and chemicals, etc. | |

| Assembly | Transferring rubber packing and plugs to the next process |

| Transferring metal parts | |

| Inspection | Sorting and transporting based on quality checks |

How to Select the Electric Gripper

Choosing the right electric gripper depends on the workpiece and application to ensure optimal performance.

Start by clearly defining the intended task. Consider workpiece material, shape, size, weight, transport speed, positioning accuracy, and safety measures for unexpected loads. Choose a product with sufficient gripping force and rigidity.

Electric grippers are used with controllers. Confirm compatibility between the selected gripper and controller.

Consider not only price but also performance, functionality, and durability when selecting an electric gripper.

Type of Electric Gripper and Shape of Attachment

Choosing the right attachment based on workpiece shape and material is essential to maximizing gripper performance.

2-finger

The 2-finger type grips the workpiece at two points. Its versatility makes it suitable for various workpiece shapes. The simple structure makes it relatively inexpensive and easy to maintain.

3-finger

The 3-finger type grips the workpiece by enclosing it at three points. It is ideal for handling round workpieces, providing stable gripping.

How to Select the Controller for the Electric Gripper (CKD Product)

CKD offers a new generation of controllers with enhanced functionality and a significantly smaller footprint while retaining essential features. This section explains how to choose a CKD electric gripper controller, including specific product examples.

Easy setting

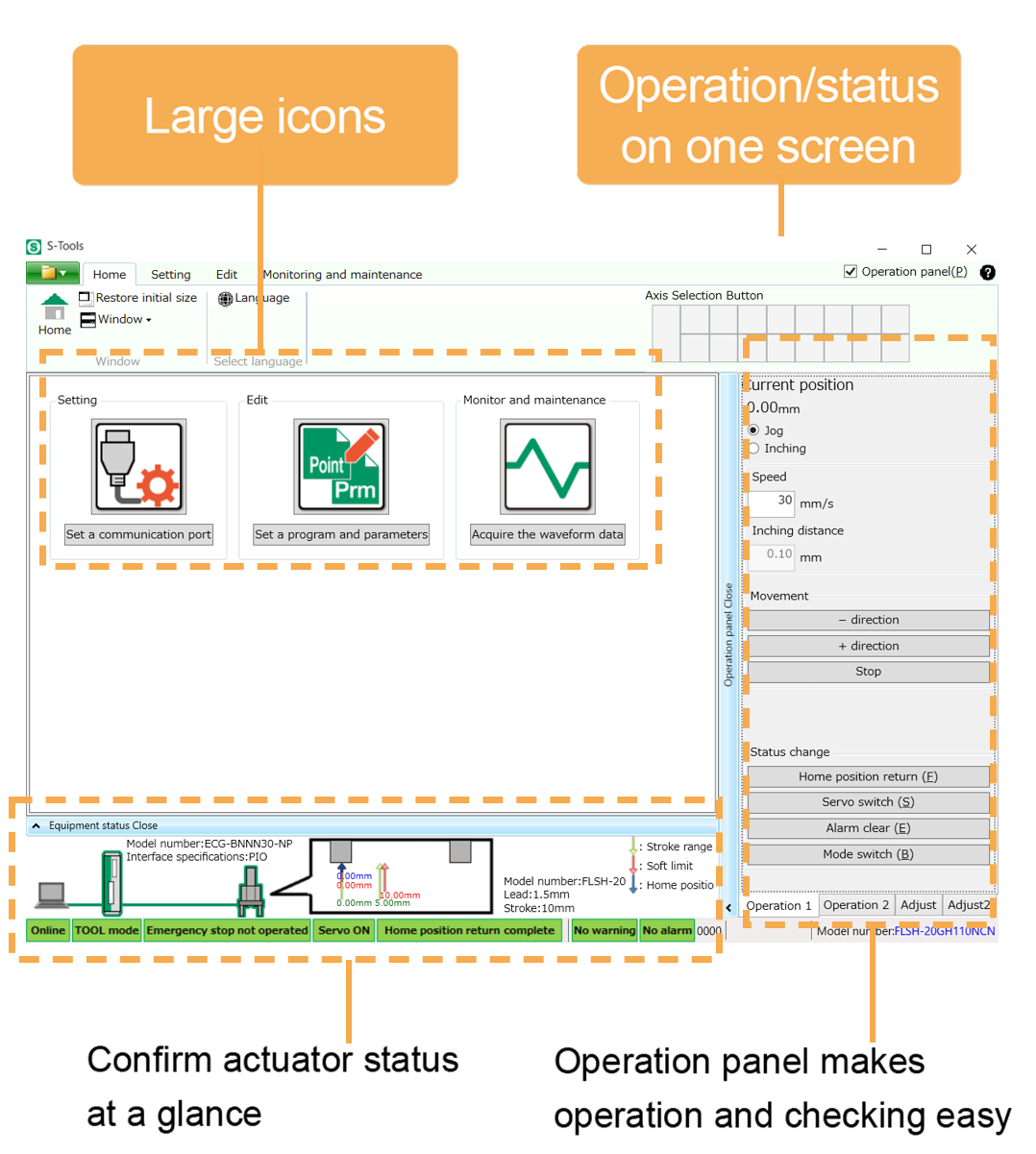

For those new to electric grippers or seeking to simplify on-site adjustments, the user-friendly controller setup is a crucial factor in their decision-making process. CKD's ECG and ECMG Series support "S-Tools," user-friendly software that simplifies setup and operation without specialized knowledge.

Space saving

Efficient space utilization is essential in automated lines. CKD offers compact controllers that save valuable space.

The ECG Series reduces the installation footprint by up to 38% compared to previous models. Controllers can be installed adjacent to each other, simplifying installation in tight spaces.

The ECMG Series, a multi-axis controller for electric actuators, supports up to 16 axes, enhancing basic performance while saving space. Choose from three power supply methods to support various actuators without current-based axis limitations.

Compatible with Compatible Models

CKD controllers offer excellent compatibility, with a single controller type supporting multiple electric gripper models and sizes.

By employing a controller that supports various models, you can simplify the selection and ordering process and achieve significant inventory reduction. This simplifies controller operation training.

Selectable Power Supply Method (CKD ECMG Series)

CKD electric gripper controllers offer flexibility in wiring methods. Choose the optimal power supply method based on your application and system configuration.

Central wiring

It supplies power to all drive units from the communication unit simultaneously. Standard wiring method.

Mixed wiring method

Power is supplied separately only to high-current drive units. The number of connected axes is not limited by current values.

Individual wiring method

Power is supplied individually to each drive unit. This method provides high safety without current-based axis limitations.

Electric Gripper with Built-in Controller (FFLD Series)

This long-stroke, low-profile electric gripper is ideal for robot end-effectors. The adjustable gripping position allows handling various workpiece sizes without tool changes. The integrated controller reduces wiring and minimizes disconnection risk.

Contributes to Downsizing of the Robot Body

The low-profile design reduces load and moment of inertia at the robot's end-effector. This allows for smaller robots and a more compact system overall.

Pursuit of Space Saving and Reduced Wiring

The low-profile design reduces load and moment of inertia at the robot's end-effector. This allows for smaller robots and a more compact system overall.

Air Chuck Option

Air chucks are widely used in manufacturing alongside electric grippers. Air chucks use compressed air to grip workpieces and have a simple structure.

Air chucks are suitable for the following cases.

●Gripping operations prioritizing speed

●Applications with fixed workpieces requiring no grip changes

●Cost-sensitive applications

●Applications requiring lightweight components

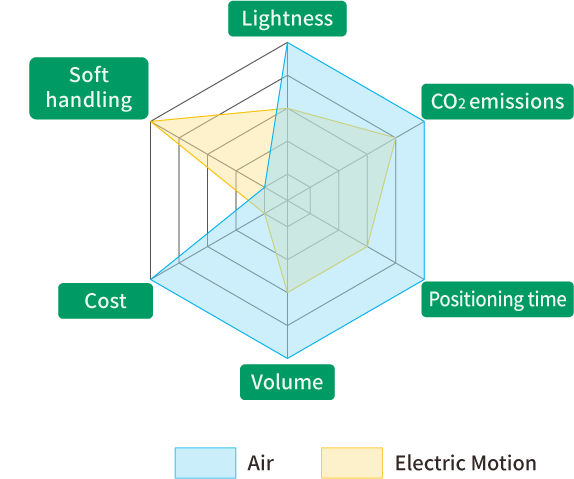

Air chucks and electric grippers have the following characteristics (see diagram below).

Note) This may differ depending on the working conditions and environment.

Choose the best option based on factors such as positioning time, soft handling requirements, cost, and environmental performance.

CKD’s Features | Track Record of Approximately 1,400 Companies Worldwide

CKD is a unique company globally, handling both automated machinery and components. We have business relationships with approximately 1,400 companies worldwide (✶) (approximately 1,100 domestic and 300 overseas), helping solve our customers' challenges. ✶ There are duplicates between regions.

Built on this experience, CKD's high-performance and reliable electric grippers are used in diverse industries, including automotive, electronics, food, pharmaceutical, and logistics.

CKD offers expert advice on model selection, custom system design, and comprehensive after-sales support for all your electric gripper needs.

CKD Product Lineup

CKD offers a wide range of electric grippers and controllers to meet diverse customer requirements.

●FLSH: "FLSH" Offers Seamless Integration into Existing Systems with Mounting Dimensions and Gripping Force Identical to the Air-Driven Linear Slide Hand "LSH".

●FFLD: Controller-integrated design for space savings.

●GCKW: Ideal for handling round workpieces.

●DLSH: Maintains workpiece grip even when power is off.

●ECG: Controller with a reduced footprint (38% smaller than previous models) while retaining familiar operation.

●ESC4: Controller with easy setup and replacement, no special tools required.

●ECMG: Multi-axis controller for electric actuators, supporting up to 16 axes.

We offer the best solution to meet your needs from our diverse range of products.

Contact CKD if You Have Problems Using the Electric Gripper

●"Considering implementing electric grippers but unsure which product to choose?"

●"Want to build the optimal electric gripper system for my company's specific needs?"

Are you facing such challenges?

With over half a century of experience leading automation and fluid control technologies, CKD offers a vast product range of over 500,000 items to meet your every need. Our experienced staff will carefully listen to customer issues and requests, and propose the optimal electric gripper.

Contact us today for a consultation.