Introduction and Selection of Air Chucks | Introduction of the Latest Model

Air chucks are essential for automated factory lines. Air chucks are used in various fields. However, many face challenges like, “There are so many types, making selection difficult,” and “I want to find the ideal air chuck for my company.” This article provides a clear explanation of air chuck basics, selection criteria, and CKD's latest air chuck series.

- 1.CKD Air Chucks

- 2.Latest HP Series Air Chucks

- 2-1.What is the HP Series?

- 2-2.HP1 Series: Greatly Improved Durability and Long Service Life

- 2-3.HP2 Series with Integrated Length Measurement Function

- 3.Air Chuck Basics

- 3-1.What is an Air Chuck? Differences between Air Grippers and Air Hands

- 3-2.Advantages and Disadvantages of Air Chucks

- 3-3.Benefits

- 3-4.Disadvantages

- 4.Materials Suitable for Air Chuck Gripping

- 5.How to Select Air Chucks

- 6.Air Chuck Types

- 6-1.Parallel Hand

- 6-2.Thin Parallel Hand

- 6-3.Wide Parallel Hand

- 6-4.180-Degree Open/Close Fulcrum Hand

- 6-5.3-Way Jaw Chuck

- 7.Items to Consider When Purchasing Air Chucks

- 7-1.Rigidity Strength

- 7-2.Ease of Replacement

- 7-3.Product Service Life

- 7-4.Length Measurement Function

- 7-5.With/Without Predictive Maintenance

- 8.Electric Gripper Option

- 9.CKD Product Lineup

- 10.Contact CKD if you have problems using the air chuck.

CKD Air Chucks

CKD offers a wide range of air chucks to meet diverse automation needs. From compact, lightweight models to wide-stroke, high-precision types, our extensive selection supports various workpiece handling requirements. Our user-friendly designs contribute to improved productivity. The HP Series, known for its high durability and long service life, is particularly popular among our customers. Some HP Series models include a length measurement function, useful for workpiece dimension verification and predictive equipment maintenance.

Latest HP Series Air Chucks

Introducing the features of CKD’s latest HP Series air chucks.

What is the HP Series?

The HP Series represents the latest advancements in air-operated equipment, significantly improving upon conventional products. The HP Series includes air chucks with extended service life (HP1 Series) and a new series with added length measurement capabilities (HP2 Series).

Conventional air chucks, especially smaller models with short strokes, presented difficulties in installing cylinder switches. The HP2 Series incorporates a built-in stroke detection sensor and amplifier within the hand body. This design enables simultaneous gripping and length measurement, even for minute workpieces, providing accurate position detection.

The HP Series combines exceptional durability with advanced control through its length measurement function, contributing to stable operation and increased productivity in production environments.

HP1 Series: Greatly Improved Durability and Long Service Life

The CKD HP1 Series air chucks offer 30% higher rigidity and four times the durability of conventional models. This extended service life significantly reduces maintenance frequency and ensures long-term stable operation.

The HP1 Series comprises a wide range of models, from small and lightweight types to thin, long-stroke, wide, and 3-way jaw chucks.

They are suitable for various processes, including assembly, handling, inspection, and mounting. Designed for demanding environments requiring high durability, the HP1 Series offers a solution for your specific needs.

HP2 Series with Integrated Length Measurement Function

The CKD HP2 Series builds upon the long service life of the HP1 Series with an innovative integrated length measurement function, addressing a key limitation of conventional air chucks. Employs a vibration- and shock-resistant* LVDT-type sensor. The integrated displacement sensor and industry-first unibody construction deliver exceptional precision. By measuring workpiece dimensions and monitoring finger wear, the HP2 Series enhances quality control and enables predictive maintenance.

✶LVDT (Linear Variable Differential Transformer) is a sensor that converts mechanical displacement into an electrical signal.

Air Chuck Basics

Do you have questions like, "What's the difference between air chucks, air grippers, and air hands?" or "There are so many types; how do I choose?" This section clearly explains air chuck fundamentals, advantages, disadvantages, and selection criteria.

What is an Air Chuck? Differences between Air Grippers and Air Hands

An air chuck is a device used in factory automation and robotics. It utilizes compressed air to grip and release workpieces. The terms "Air Grippers" and "Air Hands" are often used interchangeably with "air chuck" and are generally synonymous. While "hand" typically refers to a two-jaw gripper and "chuck" to a three-jaw gripper, there's no strict definition.

Advantages and Disadvantages of Air Chucks

Air chucks have a simple, user-friendly design, but also some drawbacks. Before implementing air chucks in your automated line, carefully consider their advantages and disadvantages.

Benefits |

・Simple structure and easy to handle

Compared with electrically driven grippers that require controller control, the structure and control are simple and easy to handle. |

・Lightweight and compact design

Compact and lightweight, it is suitable for installation in narrow spaces or for mounting on robots whose load capacity is limited. |

|

・Excellent environmental resistance

Many products are dust-proof and drip-proof, and these products can be used in environments where dust or water drops that are difficult to handle with electric grippers. |

|

Disadvantages |

・Difficult speed and cushion control

Air chucks rely on compressed air, making precise speed and gripping force control like that of electric grippers challenging. |

・Compressed air supply is required

Equipment such as a compressor is required in order to use compressed air for operation. Cost and operation costs should be considered in areas where there is no supply of compressed air. |

Materials Suitable for Air Chuck Gripping

Air chucks can handle a variety of materials, as shown in the table. Air chucks are used in various situations, including assembly, handling, and inspection processes. Compatible with materials essential to industrial products, such as metals, resins, and glass.

| Process | Examples |

|---|---|

| Assembly | Smartphone housing, electronic components parts |

| Household Appliance Packaging and Toys | |

| Smartphone screen, camera lens | |

| Handling | Conveying, packaging, and boxing in food plants |

| Filling, inspection, and packaging in pharmaceutical plants | |

| Inspection | Visual inspection of electronic parts, electrical characteristics inspection |

| PCB mounting inspection, circuit inspection |

How to Select Air Chucks

Proper selection of air chucks requires selection of products that match the workpiece characteristics and process requirements. In order to select the ideal product from the many air chucks, consider the following six points.

| Points | Details |

|---|---|

| Properties of workpiece (size/shape/weight/material/surface state/hardness) | The air chuck must be selected according to the size and shape of the workpiece. Check the workpiece diameter and the stroke required for gripping. Consider the material and shape of the air chuck's attachment according to the nature of the workpiece gripped. |

| Required speed/accuracy | The handling speed affects the cycle time. When the air chuck moves at high speed, select with a margin of gripping force. Select a high-precision air chuck for detailed work. |

| Operating environment | Environmental resistance is required in environments where dust or mist is generated. Selection according to the operating environment of the air chuck, such as with a rubber cover, is required. |

| Cost balance | Let's consider the balance between initial cost and operation cost. Even if the product price is high, choosing a product with long service life and high rigidity may result in lower operation costs. |

| Maintainability | Choose products that are easy to replace and adjust to minimize downtime. It is also necessary to consider whether the product is durable, can be replaced immediately even if it breaks, and whether predictive maintenance is possible. |

| Installation space | Select thin and lightweight types, etc., according to the size and weight limitations of the installation space. |

Air Chuck Types

Air chucks come in various types. Understanding the characteristics of each type is crucial for selecting the optimal air chuck for your workpiece shape, size, desired motion, and working environment. Here's an overview of common air chuck types.

Parallel Hand

The most common air chuck type. Two jaws move in parallel to grip the workpiece. The simple design accommodates various workpiece shapes and sizes, suitable for a wide range of applications. Due to its simple construction, parallel hands are generally less expensive.

Thin Parallel Hand

As the name suggests, thin parallel hands feature a slim, compact design. Ideal for applications with limited space or when mounting on robots with weight restrictions.

Despite their thin profile, these chucks maintain high gripping precision. Some models, like 2-piston and 4-piston designs, provide increased gripping force.

Wide Parallel Hand

Also known as wide-opening parallel hands, these chucks have jaws that move horizontally like crab claws. The left and right jaws open and close while maintaining parallelism.

The wide jaw opening accommodates various workpiece sizes.

180-Degree Open/Close Fulcrum Hand

Fulcrum hands feature a finger section that opens up to approximately 180 degrees, facilitating smooth workpiece insertion and removal. This large opening angle minimizes interference, making them suitable for complex workpiece shapes or tight clearances. It is also ideal for processes with complicated shapes or where the clearance to peripheral devices is narrow, as interference with workpieces is minimized.

3-Way Jaw Chuck

3-way jaw chucks have three jaws that move synchronously towards the center. They are ideal for gripping circular or cylindrical workpieces and provide secure clamping, necessary for high-precision machining or assembly.

Supporting the workpiece at three points, these chucks ensure stable gripping force and high centering accuracy.

Items to Consider When Purchasing Air Chucks

When purchasing an air chuck, there are several items to consider, such as operational specifications and functional aspects. Consider these key factors before purchasing an air chuck to ensure a successful selection.

Rigidity Strength

Rigidity strength in air chucks refers to the minimal deformation of the jaws when gripping a workpiece. High rigidity ensures precise positioning, stable operation, and extended service life.

Ease of Replacement

Air chucks are subject to wear and tear or damage, depending on usage frequency and the operating environment. Therefore, maintainability is essential when choosing an air chuck.

Easy replacement minimizes equipment downtime. Easy-to-replace chucks reduce maintenance costs and improve safety.

Product Service Life

Choosing a long-lasting air chuck significantly reduces replacement frequency and maintenance costs, ultimately lowering production costs.

Length Measurement Function

To increase efficiency and quality control, modern production requires more advanced functionalities than simple gripping. One such feature is the length measurement function.

This function enables air chucks to measure workpiece dimensions and accurately detect finger position.

With/Without Predictive Maintenance

Continuously monitoring finger position allows early detection of finger wear and component degradation. Early detection and prompt intervention minimize the risk of sudden equipment failure, promoting stable operation.

While predictive maintenance was challenging with traditional air chucks, CKD's length measurement air chucks leverage advanced sensing technology to make it possible.

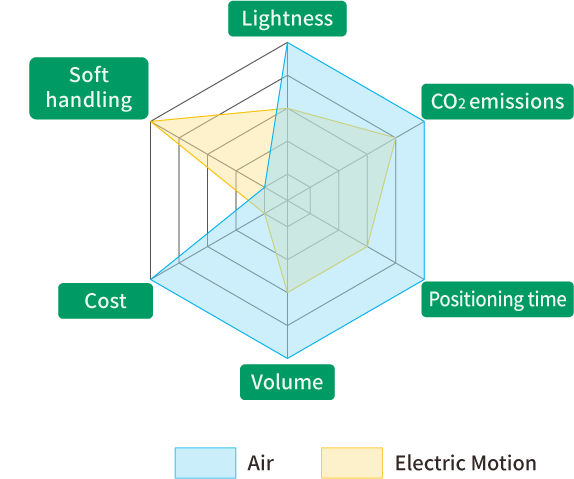

Electric Gripper Option

While air chucks offer numerous benefits, they face limitations regarding speed adjustment and cushion control. Electric grippers, powered by electricity, address these limitations.

Note) This may differ depending on the working conditions and environment.

Electric grippers are electrically driven and controlled, offering more flexible operation compared to air-driven counterparts.

CKD offers electric grippers with mounting compatibility with air chucks.

See our featured article on electric grippers for more details.

CKD Features | Supports a Wide Range of Fields and Industries with More than 500,000 Products

CKD contributes to automation across diverse industries, including medical, food, automotive, semiconductor, machine tool, and home appliance sectors, with a product lineup exceeding 500,000 items.

CKD's reputation extends beyond performance to design quality, as evidenced by 117 Good Design Awards since 1980.

Our extensive application experience, broad product range, high quality, and comprehensive support system make CKD the trusted choice for numerous customers.

CKD Product Lineup

CKD leverages years of experience and technical expertise to offer a diverse range of high-quality, high-performance air chucks suitable for various workpieces and processes.

•Parallel hand: Offers high rigidity, precision, and durability.

•Wide parallel hand: Features 1.3 times the guide rigidity and more than double the durability of conventional models.

•Fulcrum hand: Enables flexible line configurations.

•3-way jaw chuck: Provides stable gripping force and high centering precision.

We offer the optimal solution for your specific application from among our diverse product range.

Contact CKD if you have problems using the air chuck.

•Breaks quickly due to short takt time.

•Maintenance and replacement are difficult and time-consuming.

•Need to replace before failure.

CKD solves these air chuck challenges!

Our experienced staff provides comprehensive support from selection to implementation, ensuring the perfect air chuck for your workpieces, processes, and environment.

Feel free to consult us first.