Proportional Vacuum Pressure Control System

Contributing to the miniaturization

of manufacturing processes

in the rapidly growing semiconductor industry

THEME

Toward further developing cutting-edge technology industries

In the semiconductor industry, the miniaturization of manufacturing processes is progressing year by year. In line with this trend, the accuracy requirements for manufacturing equipment and components are dramatically increasing. CKD sees the uncompromising needs of its customers as an opportunity for growth, and is committed to developing equipment products with higher precision and performance while repeating verifications and improvements on a daily basis.

MISSION

Increasing performance requirements for the miniaturization of semiconductors

Of all industries, the semiconductor industry is undergoing the most remarkable technological evolution. Digital devices such as smartphones and high-speed wireless communication technologies that incorporate advanced semiconductors are prime examples. Today, everything that uses computers and radio waves relies on semiconductors, making our lives much more convenient and comfortable than they were 20 years ago. With market growth expected to continue, there are high expectations for a more prosperous future created by semiconductors, such as automated driving, artificial intelligence, and the metaverse.

In the semiconductor manufacturing process, CKD's Vacuum pressure proportional control system VEC is a key component of the equipment used in the deposition process to form thin films on objects. By precisely controlling the pressure inside the chamber, which contains a thin, circular plate made of semiconductor crystals called a wafer, the VEC meets the process requirements of semiconductor manufacturing and achieves high productivity.

At the same time, the semiconductor industry continues to evolve, and the miniaturization of the manufacturing processes is progressing year by year. Miniaturization means making semiconductor devices smaller. This enables higher speeds, lower power consumption, and lower cost, but the pursuit of miniaturization requires more high-precision equipment and components, and the required level of performance of VECs rises dramatically. For example, the performance that met the requirements until last year may turn around and require immediate improvement due to the evolution of the industry. In addition, we are sometimes consulted directly by semiconductor manufacturers, who are the end users of our products. In order to respond to the ever-changing needs of our customers, it is essential for us to collaborate with equipment manufacturers.

APPROACH

A year was spent to meet accuracy requirements, which have increased dramatically since the time of development.

What still leaves a strong impression on me is our response to the introduction of a new process in 2017, when we were required to meet the accuracy requirements in the current design, which had risen dramatically since the development of VEC. The accuracy requirements, which had risen sharply since the development of VEC, had to be met in the current design, and although they were initially addressed by overhauling, a fundamental solution had not yet been reached. In order to break out of this situation, we worked with the engineers and spent a year clarifying the factors that would satisfy the required accuracy while repeating the verification process. We were able to persuade the managers of each fab to approve the modification of the components, and we were able to successfully solve the problem and win the trust of our customers.

Once again, I believe that when a problem occurs, it is an opportunity to build a relationship of trust with the customer. Semiconductor manufacturers and equipment manufacturers, who are driving the miniaturization of semiconductors, have no room for compromise. In order to meet their demands, we need to think about what is best for the customer together with CKD's sales, engineers, quality assurance department, maintenance contractors, and other related parties inside and outside the company, and at times, we need to be persistent in our discussions with the customer. As a sales engineer of Taiwan Xi Kai Li Corporation, which is in charge of the world's most advanced semiconductor manufacturers, I try to understand the needs of our customers and work as one to tackle unknown issues in a positive manner while involving all parties involved.

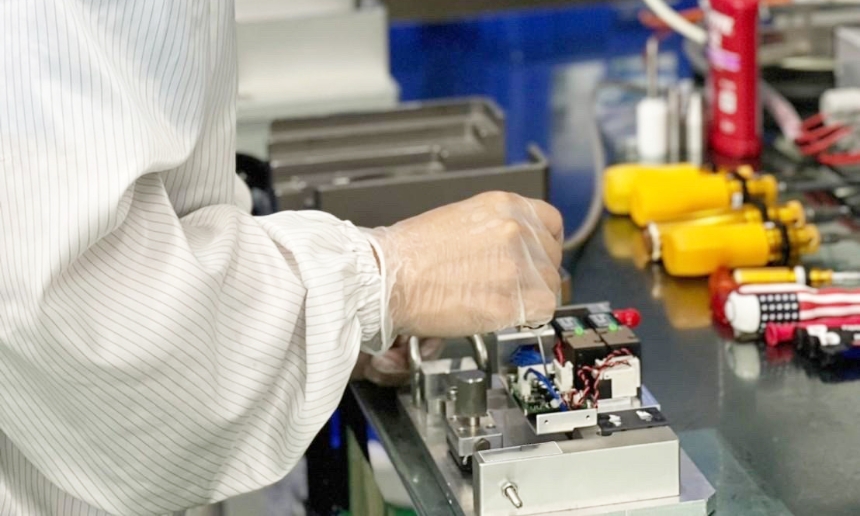

Product assembly

Proportional Vacuum Pressure Control System "VEC"

Fortunately, I have been able to build a relationship where the customer is the first to contact me whenever a new issue arises. Although I always feel tense, supporting the cutting-edge semiconductor industry on the front lines is one of the most exciting aspects of being a sales engineer.

VISION

Pursuing maintenance quality that is applicable to cutting-edge processes

VEC is an "ALL-IN-ONE" and "ONLY ONE" product that combines multiple devices that were originally employed separately into a single product. Since its launch in 1996, VEC has contributed to semiconductor manufacturing around the world while continuing to make improvements.

On the other hand, even with repeated improvements, the machine is still a machine and so it is impossible to avoid problems that may occur over long periods of operation. Therefore, it is important to minimize production line stoppages due to problems by performing regular maintenance and ensuring stable operation for as long as possible.

In the maintenance business launched in 2007, CKD has partnered with a local partner company to establish a system that can provide the same equipment and work quality as in Japan in a stable manner. Since its launch, CKD has steadily built up its reputation one by one, and has now grown to the point where it is entrusted with the maintenance of numerous pieces of equipment, contributing to the stable operation of our customers' facilities.

Of course, we are not satisfied with the status quo, and will continue to pursue maintenance quality that is applicable to cutting-edge processes. As a part of this effort, we have opened the Taiwan Xi Kai Li Tech Center in 2021, where engineers specializing in VEC will be stationed in order to quickly resolve issues in Taiwan.

Our customers will continue to evolve and change with a focus on miniaturization. No matter how much we pursue this, there is no end in sight. We will continue to build a relationship of trust with our customers through close communication so that we can accurately catch the latest needs and feed them back into our products.