Automatic Machinery

Supporting the "Technological Evolution" that challenges social issues

THEME

A development environment

that responds to changes

in the times and moves toward

technological innovation

To realize a sustainable society, Automatic Machinery and Inspection Systems with low environmental impact, safety, and high productivity are required. Furthermore, customer interest and requests are directed towards the manufacturing process of products, such as the chemicals used and the amount of waste generated. We are focusing more than ever on developing and improving our development environment so that we can pursue the sustainability of the entire manufacturing process from the design stage.

Administration Department, Automatic Machinery Business Division Naomi Hosoi

MISSION

The demand levels are changing, including a reduction in environmental load and improved packaging capacity

Based on the automatic technology that CKD has cultivated over the past 80 years since its establishment, CKD’s Automatic Machinery Division is involved in "Pharmaceutical Packaging Machines", "Food Packaging Machines", "Battery Winding Machines", "Solder Printing Inspection Machines", "Inspection Systems", and these products are used in a wide variety of industrial fields. In recent years, from the perspective of SDGs, the level of requirements for Automatic Machinery and Inspection Systems at CKD has been changing, including the adoption of eco-friendly packaging materials and development of unprecedented forms of packaging.

PTP packaging machines for pharmaceutical products such as pills and capsules are CKD's leading Automatic Machineries for which CKD maintains the top market share in Japan. In fiscal 2022, we commercialized PTP packaging using plant-derived ”Biomass Plastics” together with Astellas Pharmaceutical Co., Ltd. and Mitsubishi Chemical Group, reducing CO2 emissions by approximately 40 to 60% compared to conventional products. For the Chinese market, we launched the "FBP-600W", a high-performance machine that can package 6,000 pills a minute, and together with the "FBP-300W", a medium-performance machine that can package 3,000 pills a minute, we have launched a lineup of packaging capabilities that meet customer needs. In addition, we are promoting the development of products to meet diverse demands, such as reducing the amount of packaging materials used without reducing productivity and minimizing the amount of scrap disposal.

APPROACH

Creating a development environment to meet demand

CKD is working to create and improve the development environment to meet customer needs and social issues, including the use of data to ensure quality and safety. For example, by addressing the importance of data integrity in the pharmaceutical industry and building a system to centrally manage environmentally regulated substances used in products. In a major move, the work flow of the entire Automatic Machinery business was reviewed in FY2022. Employees familiar with each of the operations of the Automatic Machinery business, including production engineering, procurement, and manufacturing, identified a vast number of operations one by one, verified the wastefulness and unreasonableness of each, and re-planned them to ensure the smooth flow of operations. We will familiarize and educate our employees with this flow, and establish it through the PDCA cycle in actual operation.

It is also important to establish a development system. The Sales and Engineering Divisions will hold joint meetings to forecast future market changes. The development roadmap, which envisions products and services based on the required functions, is used not only to check the progress of the project, but also as a tool to align everyone's viewpoints. We believe it is important for everyone to understand how the development of elemental technologies we are working on will lead to customer value, and to recognize that our activities are aimed at creating valuable products.

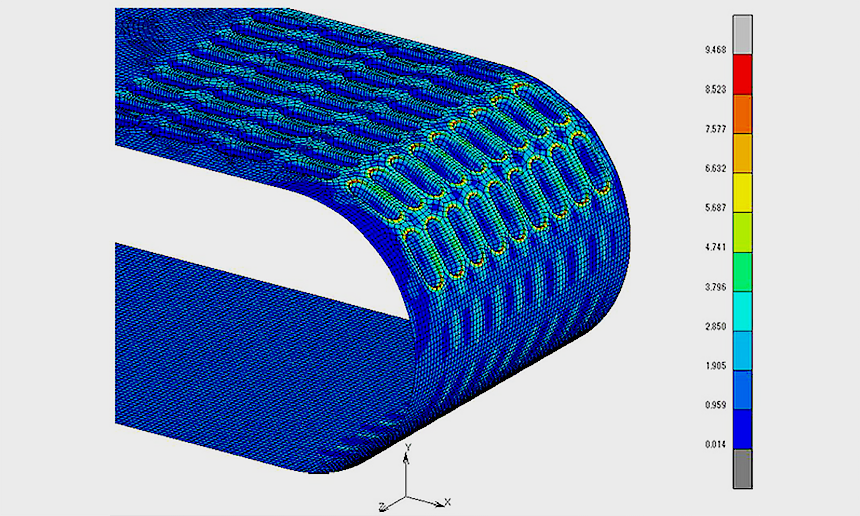

To support our customers in achieving the quality, cost, and delivery time they require, we promote the use of CAE analysis using 3D models. When a number of issues such as vibration, speed, or structural changes need to be overcome, such as the development of equipment that exceeds conventional performance, advanced simulation using CAE analysis can improve the efficiency of the design process. In addition to preventing rework, CAE analysis contributes greatly to reducing development costs by, for example, reducing the loss of material disposal through structural studies that focus on key points, and we are providing support so that many engineers can make effective use of this technology.

CAE Analysis

Example of Analysis Results: Film Winding Simulation

On the other hand, the Automatic Machinery Division offers its own level-specific Instruction program to enable engineers to acquire the necessary skills at the time they need them. The curriculum is reviewed in line with the key themes of the year, mid-career engineers prepare teaching materials, and experienced engineers serve as instructors. We are focused on improving the skills of all employees by ”Teaching” young employees to learn and mid-career engineers to ”Train”, and at the same time, passing on the automation technology that CKD has cultivated.

VISION

Change is the opportunity for growth

At CKD, we place importance on delivering products of value to our customers, and we believe that there are opportunities for growth in understanding our customers' needs. In order to leverage technological innovation and lead to new customer proposals, we will work to bridge technological, manufacturing, and Sales divisions while strengthening collaboration and gaining more trust from customers to expand our business. It is not enough to simply prepare tools and data; they are only meaningful when they are fully utilized. To this end, we intend to provide more support than ever before, including training for engineers and support that makes use of their experience and perspectives as technical experts.