Creation of worker-friendly working environment

by reducing heavy weight work

Gifu Cabinet

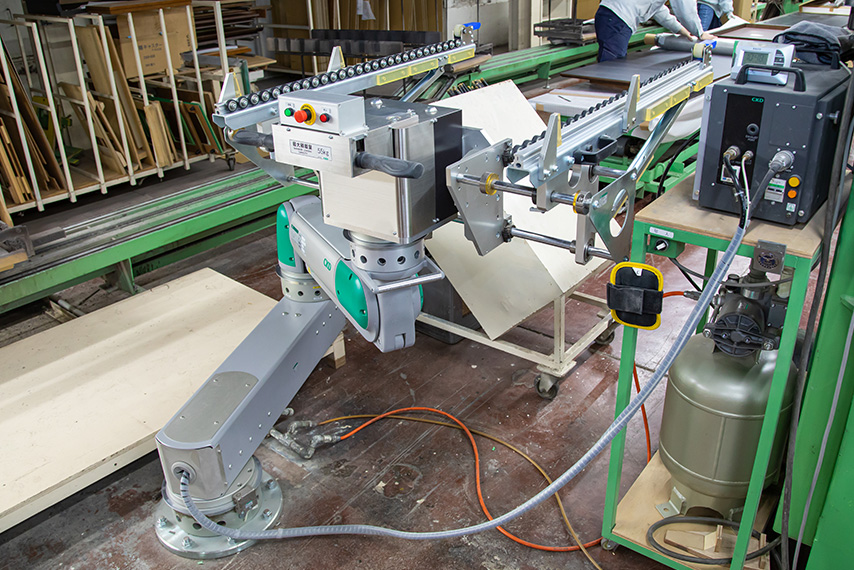

Here are some examples of improvements made in transporting TV stands using PowerArm.

As a manufacturing plant of the Karimoku Group, Gifu Cabinet manufactures wooden cabinet furniture such as TV stands, desks and bookcases,which are sold at furniture specialty stores and department stores nationwide through the sales offices of Karimoku Furniture Co., Ltd.

With the production of long and heavy products on the rise, heavy-duty work had become a task that could only be performed by designated persons.The "PowerArm" was an auxiliary device that enabled employees of all ages and genders to play an active role without any burden.

Issues

Transporting TV stands weighing up to 55 kg

With the increasing demand for large-sized TVs and the production of long and heavy products on the rise, there have been many situations where heavy-duty work by multiple people was required to ensure worker safety and prevent industrial accidents, and the work could only be performed by a predetermined number of people.

Another issue was the occurrence of defective products such as scratches and dents caused by manual handling during transportation.

Reasons for Adoption

A simple and compact transport assist device

While considering a transport assist device, the customer became interested in the PowerArm after learning about it from a video.

The deciding factors for adoption were "maneuverability that does not depend on the operator," "delicate transport," and "a wide variety of attachment options," since the product is handled close to the finished product.

Although the ceiling was low and a general top-based balancer was not available, the final decision was made on the fact that the PowerArm was able to approach from below and from the front.

The space-saving feature that allows the arm to be folded up when not in use was also attractive, as they were considering using it only when feeding heavy workpieces onto the coating line.

Variable attachment to match the workpiece

Gifu Cabinet adopted a variable attachment that allows the width of the fork to be changed to match the workpiece.We were very careful about the quality of the attachment (fork), which is the part that comes into direct contact with the product, so we made a lot of requests regarding its specifications.In this way, we are able to propose the most suitable specifications to meet the customer's needs.

Results after introduction

Contributed to reducing the number of workers required for heavy-duty work

After the introduction of the arm, the number of workers was reduced from two to one for heavy-duty work.By adopting a fork-type attachment, it was possible to secure a space between the operatorholding the control handle and the heavy object, enabling safe operation.

Stabilized input operation

The holding function when letting go of the handle enables the operator to make an intermediate stop during the operation.The hand-holding function has made it easier to maintain a balance between manual work in the line and line tact, and has also had the effect of stabilizing the feeding operation.

The company believes that improving work posture and reducing physical strain are important for improving production efficiency, and will continue to work on creating a workplace where workers can maximize their abilities.