What is the Mechanism of Condensation? | An Explanation from Two Scenarios: General Households and Factories

Condensation occurs in various places, such as on the windows and walls of homes and on the surfaces of factory equipment, affecting both our daily lives and industrial activities. This article will explain the mechanism of condensation in detail and introduce the specific effects and countermeasures for condensation in both household and factory settings.

- 1.What is Condensation?

- 2.The Mechanism of Condensation (Dew Point and Saturated Water Vapor Amount)

- 3.Conditions Prone to Condensation | Temperature Difference and Humidity

- 4.[For Households] Effects on Daily Life and Countermeasures

- 5.[For Industry] Condensation Problems in Factories and Industrial Facilities

- 6.Examples of Condensation Occurrence by Industry

- 7.Drain Countermeasures in Pneumatic Systems

- 8.Condensation Countermeasures in Industrial Facilities (Building Side)

- 9.Drain Countermeasures in Industrial Facilities (Equipment Side)

- 10.Condensation Countermeasures with CKD's Quick Exhaust Valve with One-touch Fitting

What is Condensation?

Condensation is a phenomenon where water vapor (a gas) in the air turns into liquid water droplets upon contact with a cold surface. When warm air is suddenly cooled, the water vapor in it condenses into water droplets.

The Mechanism of Condensation (Dew Point and Saturated Water Vapor Amount)

The occurrence of condensation is deeply related to air temperature and moisture content. Here, we will explain in detail the "saturated water vapor amount" and "dew point," which are essential for understanding condensation.Here, we will explain in detail the "saturated water vapor amount" and "dew point," which are essential for understanding condensation.

The Limit of Moisture Content in the Air (Saturated Water Vapor Amount)

The air contains water vapor that is invisible to the eye. The amount of this moisture in the air is determined by the air's temperature, and the maximum amount of water vapor that it can hold is called the saturated water vapor amount.

Warmer air can hold more water vapor, while colder air can hold less.

What is Dew Point Temperature?

The temperature at which water vapor in the air begins to condense and turn into water droplets is called the dew point temperature. If you lower the temperature without changing the amount of water vapor in the air, the humidity will reach 100% at a certain point, and water droplets will begin to form. This temperature is the "dew point."

The Mechanism of How Condensation Occurs

Even if it's invisible, the air always contains a certain amount of water vapor.

When the air temperature drops, it can no longer hold all the water vapor it previously contained, and the excess appears as water droplets.

The Relationship Between Adiabatic Expansion and Condensation

When you use a spray can, you may notice the can feels cold. This is because a phenomenon called adiabatic expansion occurs when the liquid inside is sprayed out.

Adiabatic expansion is when a gas or liquid expands without receiving heat from the outside.In a spray can, the liquefied gas that was compressed at high pressure expands rapidly when released, causing its temperature to drop.As a result, the can itself becomes cold.

Such adiabatic expansion can be observed in everyday situations.When the air temperature drops, the saturated water vapor amount decreases, and the air can no longer hold some of the water vapor it previously held as a gas. As a result, fine water droplets (mist-like droplets) may appear.

If this phenomenon occurs repeatedly, water droplets will adhere to and accumulate inside piping, eventually becoming visible condensation.

Conditions Prone to Condensation | Temperature Difference and Humidity

The occurrence of condensation is greatly influenced by temperature and humidity. Here, we explain how each of these conditions affects the occurrence of condensation.

Temperature Difference and Exceeding the Dew Point

Condensation mainly occurs with a combination of "warm, moist air" and a "cold surface."

For example, in an environment with a large temperature difference between indoors and outdoors, or when a cold drink is poured into a glass, the dew point is exceeded, and condensation occurs.

The Higher the Humidity, the Higher the Dew Point Temperature

If you use a humidifier indoors or if the humidity level rises due to people's breathing, condensation is more likely to occur even at higher temperatures.

This is because the higher the humidity, the more water vapor is present in the air, making it easier to reach the dew point temperature.

Differences in Condensation Occurrence by Season

In winter, the large difference between indoor heating and outdoor temperatures makes condensation likely to form on window panes and walls.

Also, summer is a season prone to condensation because it is hot and humid, and the use of air conditioning causes moist indoor air to come into contact with cold walls and windows.

Condensation is more likely to occur in seasons with large temperature changes, such as winter and summer.

[For Households] Effects on Daily Life and Countermeasures

Condensation in daily life can cause various problems.

Growth of Mold and Mites

Condensation on window panes, sashes, and wall surfaces is a phenomenon experienced by many. When window panes, sashes, and walls are constantly wet due to condensation, it becomes easier for mold and mites to grow and multiply.

In an environment where mold is present, mold spores can easily spread indoors. Inhaling these spores can cause allergic symptoms or worsen respiratory conditions like asthma.

At the same time, mites that feed on mold also tend to proliferate. Mold spores and the feces/carcasses of mites become airborne and can cause allergic symptoms such as allergic rhinitis and atopic dermatitis. Particular caution is necessary in households with small children or individuals with allergies.

Deterioration of Building Materials (Corrosion/Decay)

In wooden houses, when condensation causes the wood to become damp, it becomes easier for wood-decay fungi to grow. These fungi break down the wood's structure, significantly reducing its strength and thus compromising the durability of the house.

Additionally, if condensation forms on steel frames or metal parts, rust and corrosion can progress.

Condensation Prevention Measures at Home

Frequent ventilation and the use of dehumidifiers are effective.Be especially mindful to ventilate areas with water fixtures at times when humidity is likely to be high, such as after bathing or cooking.Keeping indoor humidification moderate is also an effective measure.

The greater the temperature difference between outside and inside, the more likely condensation is to occur.In winter, it is also effective to set heaters to around 20°C and avoid raising the room temperature too much.

If condensation does occur, wipe it away promptly to prevent mold growth.

[For Industry] Condensation Problems in Factories and Industrial Facilities

In industrial facilities such as factories and warehouses, condensation can have serious effects on products and equipment. In food factories, precision equipment manufacturing sites, pharmaceutical facilities, and refrigerated warehouses, the occurrence of condensation is a challenge at many sites. If left unchecked, it can lead to quality degradation and equipment trouble.

To manufacture products stably in such environments, a correct understanding of condensation and its countermeasures is essential.

Examples of Condensation Occurrence by Industry

Condensation is likely to occur in environments with inadequate temperature and humidity control, and it can cause serious quality-related problems, especially in the manufacturing industry.

Condensation in Food Factories

Some areas inside food factories are kept at low temperatures to maintain product quality.As a result, the relative humidity indoors becomes high, and condensation forming on ceilings and pipes becomes a major problem.

In particular, areas around refrigeration/freezing equipment and cooling processes have low temperatures and are environments where water droplets are likely to form.If these droplets get into the food, mold and bacteria can multiply, potentially compromising product safety significantly.

As a general rule, all food business operators are obligated to implement hygiene management in line with HACCP.HACCP management items include facility hygiene management and air conditioning systems, making condensation countermeasures an essential element in ensuring food safety.

Condensation in the Precision Equipment and Electronic Components Manufacturing Industry

In manufacturing sites that handle precision machinery and electronic components, condensation poses a significant risk of equipment failure and product defects.If water droplets adhere to electronic devices or circuit boards, it can cause short circuits or corrosion, greatly diminishing product reliability.

For example, a cleanroom is a clean space with few airborne particulates or microorganisms.In cleanrooms, humidity management is performed in addition to cleanliness control.

Precision equipment and electronic components are housed in enclosures with high water resistance, but it is not uncommon for moisture to enter through small gaps and cause condensation inside.Especially in environments with large temperature fluctuations, the saturated water vapor amount of the air inside the enclosure changes, increasing the risk of condensation.

Precision equipment and electronic components themselves are parts that are very vulnerable to moisture.Even a single drop of water can have a serious impact on the manufacturing process.

Condensation in the precision components and electronic parts manufacturing industry

In manufacturing sites handling precision machines and electronic parts, equipment breakdowns and product defects due to condensation are a significant risk. Water droplets adhering to the electronic components or the substrate can cause short-circuiting or corrosion, greatly damaging the product's reliability.

Condensation in Pharmaceutical Factories and Cleanrooms

In pharmaceutical factories and cleanrooms, even slight condensation poses a serious risk.Maintaining a sterile environment is an absolute requirement, so situations where water droplets adhere to ceilings or walls, leading to mold growth, are completely unacceptable.

In recent years, the pharmaceutical industry, like the food industry, has been required to implement more advanced hygiene management.Condensation caused by inadequate air conditioning system design or insufficient insulation measures may be considered a violation of GMP (Good Manufacturing Practice).

The lifecycle management of pharmaceuticals as defined by GMP requires stability monitoring.This is a system to continuously check and ensure that quality is consistently maintained.For general active pharmaceutical ingredients and formulations, it is necessary to monitor the cleanliness and the temperature/humidity within the room.

Therefore, condensation management can be considered a very important element in ensuring product quality assurance and safety.

Drain Countermeasures in Pneumatic Systems

In pneumatic systems, the generation of drain is an unavoidable issue, and if left unattended, it can lead to various troubles.

The Relationship Between Pneumatic Systems and Drain

The compressed air sent from a compressor always contains moisture.As this moisture flows through the piping, it condenses due to temperature changes and appears as drain, a mixture of water droplets and oil.Drain can cause compressor performance degradation, failure, and pipe corrosion, so appropriate countermeasures are necessary.

The Mechanism of Condensation and Drain Generation

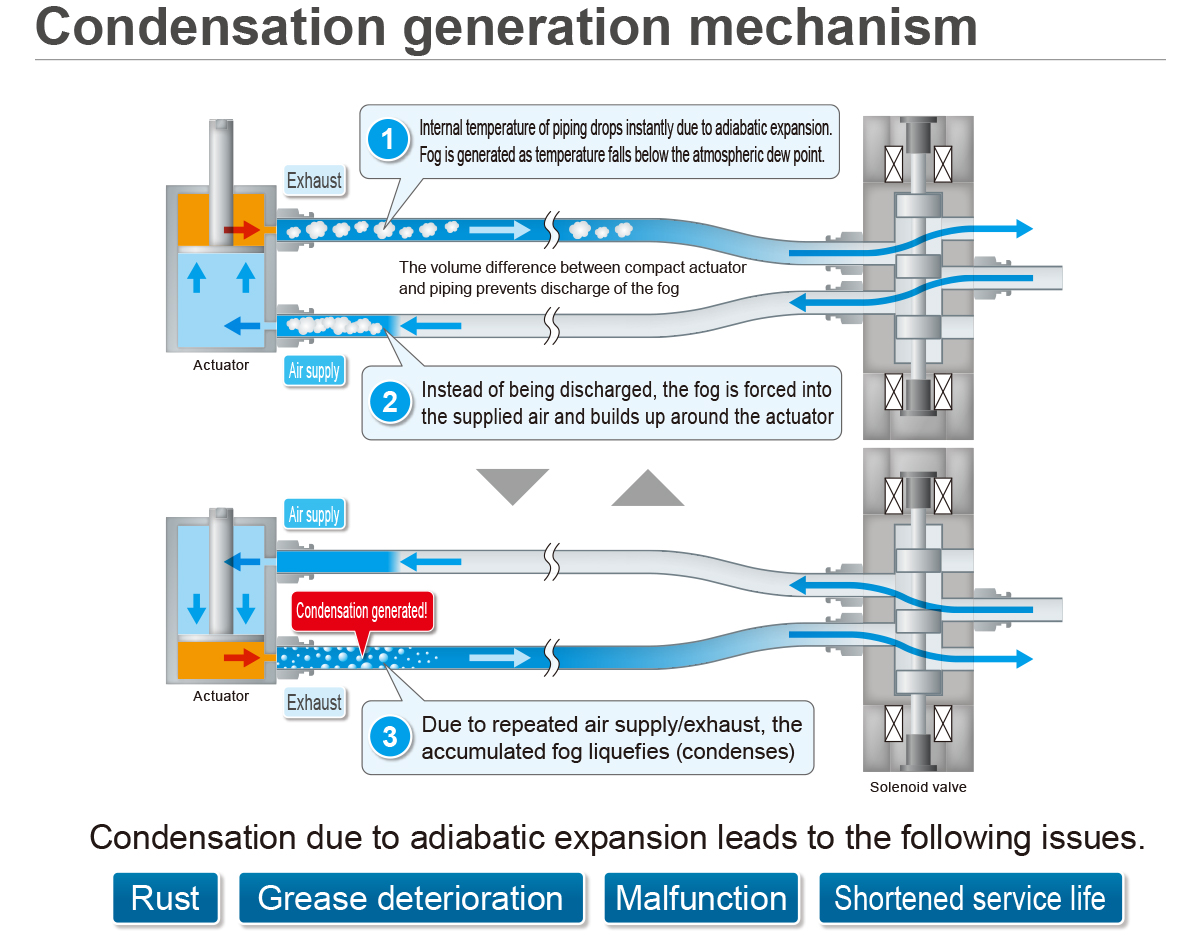

When a directional control valve switches and compressed air is exhausted from the cylinder into the piping, the drop in pressure causes the compressed air to expand rapidly.During this compression process, the air temperature rises, but at the same time, the amount of water vapor per unit volume also increases.

The compressed air is cooled as it passes through an aftercooler or piping.When the temperature drops, the saturated water vapor amount of the air decreases, and the excess water vapor that can no longer be held condenses to become drain.

Condensation also occurs in pneumatic systems.When a directional control valve switches and compressed air is exhausted from the cylinder into the piping, the drop in pressure causes the compressed air to expand rapidly.As a result, the temperature inside the piping drops, making it easier for moisture in the air to condense (adiabatic expansion).

Problems Caused by Drain

The main component of drain is water, and when it adheres to the inside of metal components like pneumatic equipment and piping, it accelerates rust and corrosion.

Rust not only shortens the life of the equipment, but particles of exfoliated rust can flow into downstream equipment, causing further trouble.In particular, the occurrence of rust inside valves and cylinders can lead to critical failures.

If drain enters the sliding parts of cylinders or valves, it can wash away lubricants (such as grease).If the grease deteriorates or is washed away, sliding resistance increases, leading to malfunction, component wear, and deterioration of sealing materials.In the worst case, it may cease to operate.

In addition, in low-temperature environments where drainage may freeze, there is a risk of malfunction in pneumatic equipment. Therefore, installation of a drain separator is also recommended.

Condensation Countermeasures in Industrial Facilities (Building Side)

Insulation and Heat Shielding Measures

One of the main causes of condensation is the temperature difference between inside and outside.In particular, when roofs, walls, and floors that are easily affected by the outside temperature are cooled, condensation is more likely to occur on their surfaces.

In response, applying insulation to the building's roof, walls, and floors can prevent heat from entering from the outside or escaping from the inside, bringing the surface temperature of the structure closer to room temperature.

Additionally, applying heat-shielding paint to the roof or exterior walls, or installing heat-shielding sheets, can suppress heat absorption from sunlight and reduce heat infiltration into the building.By implementing such measures, you can prevent rises in room temperature in the summer and reduce the load on air conditioning, while also lowering the risk of condensation.

Improvement of Ventilation and Air Conditioning Control

Ventilation is necessary to efficiently exhaust water vapor generated within the facility.In areas where humidity can become locally high (e.g., processes that use a lot of steam, washing areas), install dedicated exhaust fans to promptly remove moist air.

Attention should also be paid to the air conditioning settings during non-operating hours, such as at night or on holidays.Lowering the room temperature or raising the humidity more than necessary increases the risk of condensation.

Dehumidification, Humidity Management, and Dew Point Management

If the overall facility humidity is high, or if local dehumidification is required, consider installing a dehumidifier.The introduction of humidity sensors and dew point meters is also effective.

Since you can grasp the temperature at which condensation might occur under the current temperature and humidity conditions (the dew point temperature), you can detect the risk of condensation in advance and take preventive measures such as ventilation, dehumidification, and adjusting air conditioning settings.

Drain Countermeasures in Industrial Facilities (Equipment Side)

Drain countermeasures for air piping in factories are mainly implemented at three points, depending on the location of generation and the objective: "upstream," "midstream," and "end/downstream."

Upstream

The basis of drain countermeasures is to remove moisture immediately after the compressor, which is the source of the compressed air.By installing an air dryer here, you can effectively lower the dew point temperature of the compressed air.

If you can lower the dew point upstream, you can significantly suppress the inflow of moisture into the entire piping system and reduce the risk of drain generation downstream.

Midstream

Even with compressed air treated by an air dryer, moisture can re-condense and form drain mid-stream due to temperature changes or pressure fluctuations in the piping.Therefore, it is necessary to install drain discharge devices (drain traps) at points where drain is likely to accumulate, such as low points in the piping or at branch points, and to periodically discharge the drain once a certain amount has accumulated.

Intentionally sloping the piping to collect and discharge drain is also an effective method.

End / Downstream

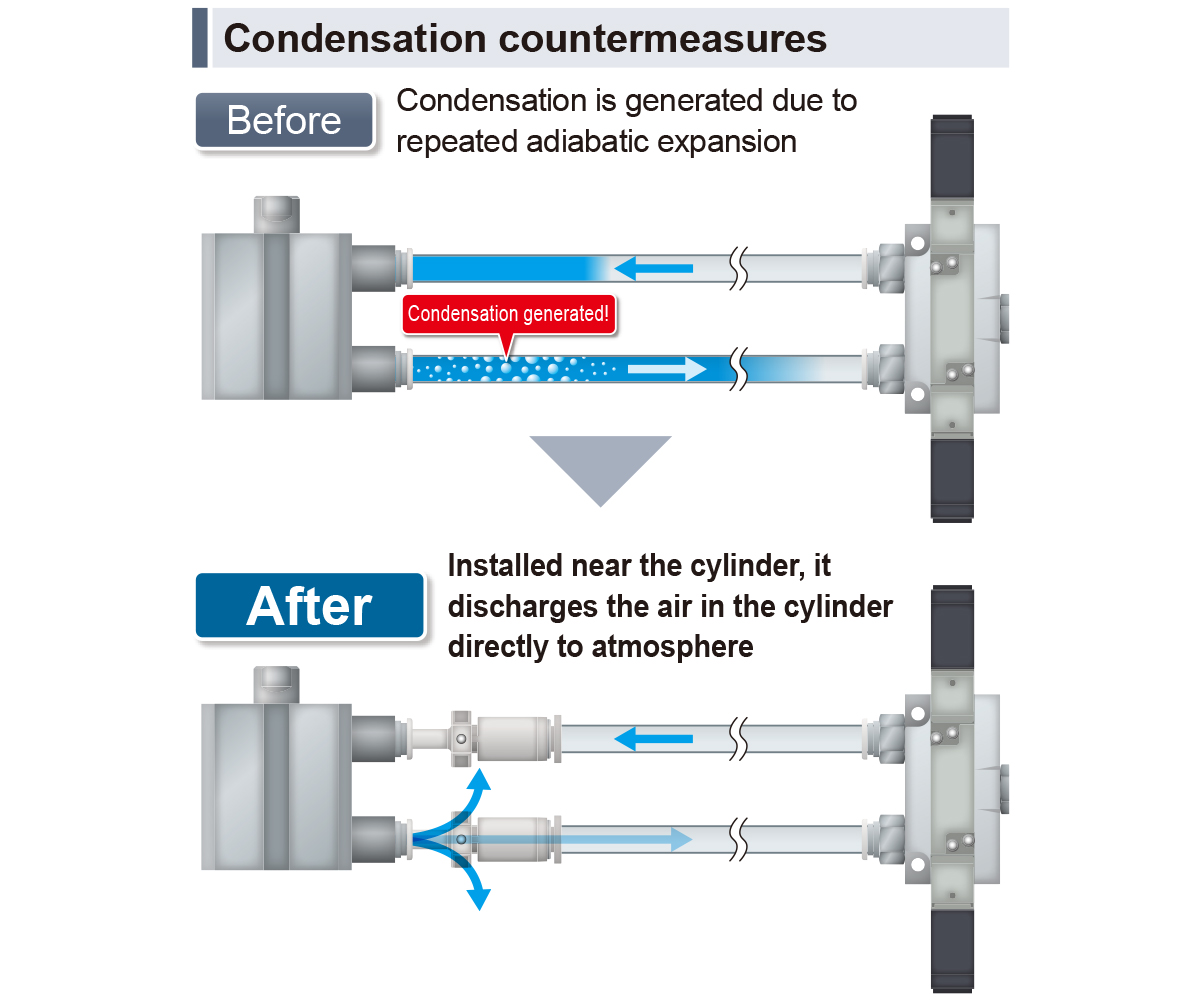

Near actuators such as air cylinders (at the end/downstream), adiabatic expansion occurs when the directional control valve switches and compressed air is exhausted, causing a sharp, localized drop in temperature and making condensation more likely.

An effective countermeasure for this is a quick exhaust valve.By installing a quick exhaust valve near the actuator's exhaust port, the air inside the actuator is exhausted directly to the atmosphere, effectively suppressing adiabatic expansion within the piping and the accompanying condensation.

Condensation Countermeasures with CKD's Quick Exhaust Valve with One-touch Fitting

Condensation in pneumatic systems is a troublesome problem that causes equipment malfunctions and reduced service life.

The QEL series, when installed near an actuator (such as a cylinder), exhausts the air from within the actuator directly to the atmosphere.This prevents adiabatic expansion inside the piping and significantly suppresses the occurrence of condensation.

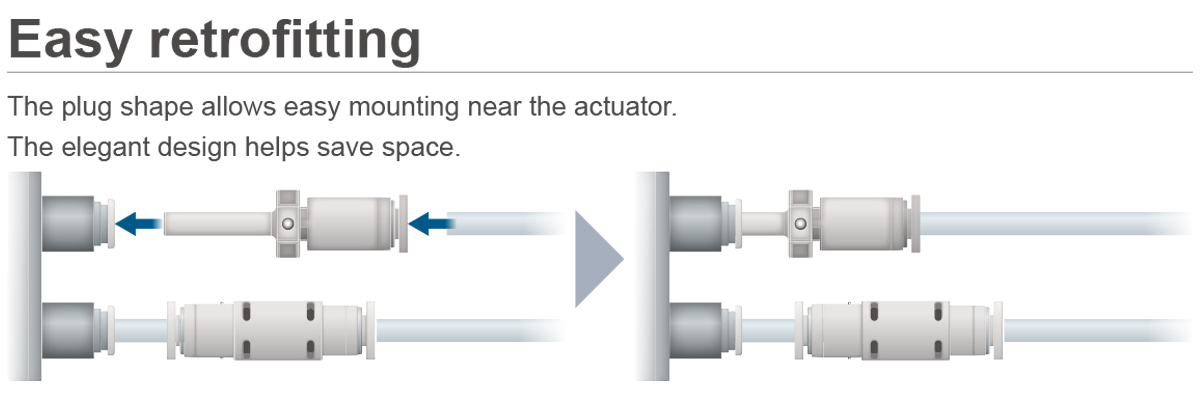

Additionally, the plug type can be easily retrofitted without changing existing piping equipment. Thanks to its compact design, finding installation space is not an issue.

If you are having trouble with condensation countermeasures or improving responsiveness in your pneumatic system, please consider CKD's QEL series.

For product details or consultation, please feel free to contact us via the following.