What are Electro-Pneumatic Regulators? From Basic Information to Inspection Methods and Troubleshooting

Electro-pneumatic regulators are widely used in industrial fields requiring advanced pressure management, such as semiconductor manufacturing equipment and liquid coating equipment, contributing to automation and quality improvement. This article introduces practical information about electro-pneumatic regulators, covering basic functions and characteristics, selection points, maintenance methods, and troubleshooting.

- 1.What is an Electro-Pneumatic Regulator?

- 2.Basic Characteristics

- 3.Main Components of Electro-Pneumatic Regulators

- 4.Information Required for Selecting Electro-Pneumatic Regulators

- 5.Inspection and Maintenance Methods for Electro-Pneumatic Regulators

- 6.Causes and Troubleshooting Methods for Problems (Troubleshooting)

- 7.Industries and Fields Where Electro-Pneumatic Regulators are Used

- 8.Difference between Electro-Pneumatic Regulators and Air Regulators

- 9.CKD's Electro-Pneumatic Regulators

What is an Electro-Pneumatic Regulator?

An electro-pneumatic regulator is a device that varies air pressure in proportion to an electrical signal. Classified as proportional control valves, they continuously control the output air pressure according to the input electrical signal. Because pressure can be adjusted steplessly, high-precision pressure control is possible. Unlike manual regulators, pressure can be adjusted remotely even during operation.

Basic Characteristics

Electro-pneumatic regulators have the following four features.

Precision Pressure Control

Unlike conventional manual regulators, pressure and flow rate can be freely varied by electrical signals, enabling stepless continuous control using electrical control devices.

When used as a system, a circuit is formed where signals from the host controller are converted by a D/A (Digital-to-Analog) converter to signals such as DC 0-10V, operating the electro-pneumatic regulator via the controller to freely control the thrust and speed of various actuators.

Feedback Control

Electro-pneumatic regulators incorporate an internal pressure sensor, which constantly monitors the output pressure.

By automatically adjusting the pressure while constantly monitoring the output pressure, stable pressure control is enabled even with changes in the external environment or load fluctuations.

Furthermore, the latest electro-pneumatic regulators employ a new control method that corrects steady-state deviation (the difference between the target value and the output control value in a steady state), enabling even higher precision pressure control.

Communication Function

Electro-pneumatic regulators support industrial communication protocols such as CC-Link, DeviceNet, and IO-Link, enabling linkage with host networks. They also support remote pressure setting and monitoring, as well as centralized management of multiple electro-pneumatic regulators.

For example, with CC-Link compatible electro-pneumatic regulators, it is possible to change pressure set values and read current output pressure values from the PLC. Additionally, abnormal diagnostic information can be acquired via communication, making it useful for predictive maintenance.

With IO-Link compatible models, more detailed parameter settings and acquisition of diagnostic information are possible, advancing compatibility with Industry 4.0 and IoT.

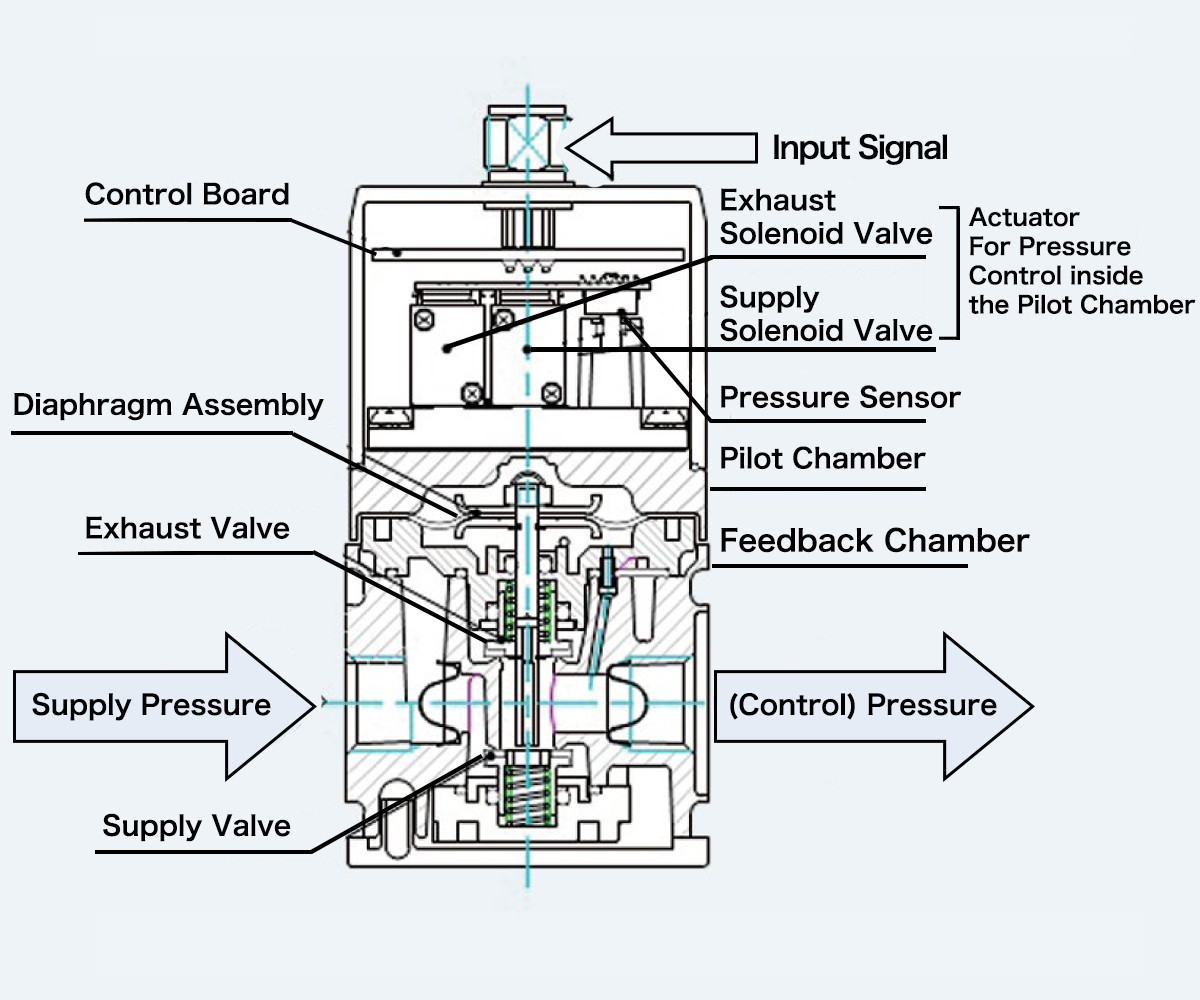

Main Components of Electro-Pneumatic Regulators

| Part Name | Details |

|---|---|

| Control Board | Its main role is processing input electrical signals and executing feedback control. The control board executes advanced control algorithms and functions as the central part realizing high-precision pressure control. |

| Pressure Sensor | The pressure sensor detects the output pressure with high precision and sends the signal to the control board. The detected pressure signal is processed by the control board and used to calculate the deviation from the set value. |

| Supply Valve/Exhaust Valve | The supply valve connects the supply pressure and the output port, while the exhaust valve connects the output port and the exhaust port. The supply and exhaust valves operate in conjunction with the diaphragm assembly to control pressure. |

| Pilot Chamber | The pilot chamber is the space where pressure control takes place. It receives pressure from the supply/exhaust solenoid valves and uses that pressure to operate the diaphragm. |

| Feedback Chamber | Pressure is controlled so that the pressure balance between the pilot chamber and the feedback chamber becomes constant according to the input signal. |

Information Required for Selecting Electro-Pneumatic Regulators

When selecting an electro-pneumatic regulator, it is necessary to understand the following information.

Confirmation of Pressure Conditions

It is necessary to confirm the primary pressure (high pressure) and secondary pressure (low pressure). Select a regulator with a pressure range compatible with the pressure required by the air tools or equipment being used.

Understanding Flow Rate

Accurately determine the flow rate required by the air tools or system being used. For example, if a specific air tool requires 300 L/min of air, a regulator capable of handling that flow rate must be selected.

Usage Conditions

Select considering necessary functions, such as limitations in wiring or installation space, and the presence or absence of pressure or error displays.

Confirmation of Piping Size

Regulators may have different sized threads for the inlet and outlet ports. It is necessary to choose a size compatible with the piping being used.

Input Signal

Input signals such as 0-10 VDC, 0-5 VDC, 4-20 mA, parallel 10bit, 0-20 mA, 1-5 VDC, variable resistance input, and IO-Link can be selected.

Not all electro-pneumatic regulators are compatible with all input signals. It is necessary to select a model compatible with the required signal.

Other

Choose appropriate products and options, such as cables, brackets, and fittings, according to the input signal, usage environment, and purpose.

Inspection and Maintenance Methods for Electro-Pneumatic Regulators

Regular inspection and maintenance are essential for long-term use of electro-pneumatic regulators. For maintenance, turn OFF the power in advance, stop the supply of compressed air, and confirm there is no residual pressure.

Frequency of Inspections

Regular inspection and maintenance are essential for long-term use of electro-pneumatic regulators.

| Items to check at least once per year | Contents |

|---|---|

| Supply Compressed Air Pressure Management | Is it supplied at the set pressure? |

| Does the pressure gauge indicator show the set pressure during device operation? | |

| Pneumatic Filter Management | Is drain discharged normally? |

| Are the bowl and element clean? | |

| Compressed Air Leak Management at Piping Connections | In particular, is the connection status of moving parts normal? (Leaks in piping may cause abnormal operation) |

| Operating Status Management | Is there any delay in operation? |

| Is the exhaust status normal? | |

| Pneumatic Actuator Operating Status Management | Is the operation smooth? |

| Is the end-stop state normal? | |

| Is the connection with the load normal? |

The frequency of defects varies depending on the environment and usage frequency. Therefore, initially perform inspections at short intervals and set the inspection cycle while observing the situation.

Causes and Troubleshooting Methods for Problems (Troubleshooting)

If it does not operate as intended, inspection is necessary according to the table below.

| Problem Phenomenon | Cause | Troubleshooting Method | |

|---|---|---|---|

| Loud humming noise occurs | There is a large leak exceeding the maximum flow rate | Continued use in this state extremely shortens lifespan; reconsider usage method | |

| Air bypass exceeding relief performance from secondary piping | Continued use in this state extremely shortens lifespan; reconsider usage method | ||

| Power is ON and input signal is set while primary pressure is not supplied | Set power supply and input signal while primary pressure is supplied | ||

| Input signal exceeding primary pressure is set | Ensure primary supply pressure is at or above the minimum operating pressure | ||

| Primary pressure is below the minimum operating pressure | Ensure primary supply pressure is at or above the minimum operating pressure | ||

| Pressure of 1% F.S. or more is output even when power is OFF | Power was turned OFF while the input signal was set | Turn the power supply ON and set the input signal to 0% | |

| Left for a long time with primary pressure supplied while power was OFF | If not used for a long time, reduce primary pressure to zero In the unlikely event that the secondary pressure has risen, turn the power ON and set the input signal to 0% |

||

| Product has failed | Reconfirm that piping and wiring are normal, then replace the product | ||

| Primary pressure is output directly | Product has failed | Reconfirm that piping and wiring are normal, then replace the product | |

| Pressure cannot be controlled | Input signal is abnormal | For analog types, confirm if the input signal common and power supply ground are commonly wired | |

| Pressure sensor has failed | Replace the product Confirm there is no possibility of excessive pressure on the secondary side due to bypass from other piping, etc. |

||

| Pressure is not output | Primary pressure is not supplied | Confirm that the primary supply pressure is at or above the minimum operating pressure | |

| Wiring is abnormal | Reconfirm that wiring is normal Also, confirm that the connector is connected normally |

||

| Pressure does not rise to the set pressure | Primary pressure is insufficient | Ensure primary supply pressure is at or above the minimum operating pressure | |

| Pressure does not decrease | Exhaust port flow path is blocked | Arrange for air exhaust from the R port and EXH port. | |

| Pressure is unstable | Power supply voltage is unstable | Use a stabilized power supply that meets the specifications of this product for the power supply voltage | |

| Input signal is unstable | Check the influence of noise Connect the shield wire to the ground on the power supply side |

||

| Primary pressure is unstable | Install a regulator on the primary side | ||

| There is a leak in the piping | Check for leaks in the primary and secondary piping | ||

| Pressure oscillates | Primary pressure is too high relative to the control pressure | Lower the primary supply pressure as much as possible within the range that ensures it is at or above the minimum operating pressure | |

| Mismatch in secondary piping volume, leaks, foreign matter contamination, etc. | Oscillation can sometimes be avoided by changing piping conditions; try adjusting secondary piping diameter, increasing/decreasing load volume, reviewing leaks, etc. ※Pressure may stabilize by changing the proportional value (decreasing the proportional value). |

||

Industries and Fields Where Electro-Pneumatic Regulators are Used

Electro-pneumatic regulators are utilized in various industrial fields requiring high-precision pressure control.

Particularly in semiconductor manufacturing equipment, they are adopted in processes requiring precise pressure management, such as wafer transfer and holding, and pressing control in polishing processes. They are also used for pressure control in various coating equipment during the manufacturing processes of LCD panels and touch panels.

In the pharmaceutical manufacturing field, they are used in processes requiring high quality control, such as tablet pressing pressure control and quantitative dispensing control of liquid medicines.

They are also utilized in the following industrial fields:

・Filling pressure control in food manufacturing processes

・Tension control in film manufacturing processes

・Gripping force control in the robot industry

・Printing pressure control in Printing machinery

Difference between Electro-Pneumatic Regulators and Air Regulators

The main difference between electro-pneumatic regulators and air regulators lies in the control method. Electro-pneumatic regulators automatically control pressure based on electrical signals, whereas air regulators adjust pressure manually.

Electro-pneumatic regulators can steplessly adjust the output pressure according to the input electrical signal, enabling remote operation and automatic control. Additionally, feedback control achieves high-precision pressure control.

On the other hand, air regulators are mechanisms that adjust pressure by manually turning a handle, maintaining the set pressure constant after adjustment. Refer to the following for details on the air Regulators.

CKD's Electro-Pneumatic Regulators

CKD offers a high-performance lineup of electro-pneumatic regulators that meet the diverse needs of industry.

These regulators feature high-speed response and excellent stability, making them suitable for various systems requiring tension control and pressure adjustment. Furthermore, CKD products feature space-saving design and simple operability, supporting the efficiency improvement of production lines.

For detailed product information, refer to the CKD electro pneumatic regulator product list.

Contact us today for a consultation.