What is a balancer? Applications and Selection Method

Manually transporting heavy objects required for work in plants. The Labor Standards Act and the Notice of the Ministry of Health, Labor and Welfare (*1) stipulates the maximum weight that can be transported by human power. In practice, there are many cases where heavy objects are carried by hand, and the fact is that workers are often limited and suffer from back pain.

This is why the balancer, a device that assists in the manual handling of heavy objects, is attracting attention. Balancers are reducing the burden on workers in manufacturing and other factories and job sites.

(*1) Ministry of Health,"Labor and Welfare "Visualization" of the weight handled by men over the age of 18"(Link to Japanese page of Ministry of Health and Welfare in Japan)

- 1.What is a balancer?

- 2.Mechanisms often compared to Assistive Devices

- 2-1.CKD balancer (PowerArm)

- 2-2.Arm Balancer

- 2-3.Hoisting Balancer

- 2-4.Power Suit

- 2-5.Industrial Robots

- 3.Balancer Selection Criteria

- 4.Features of CKD PowerArm

- 5.Example of CKD PowerArm Attachments

- 5-1.Suction of corrugated cardboard

- 5-2.Suction of material bags

- 5-3.Suction of 18 L cans

- 5-4.Container box container

- 5-5.Roll material inner diameter clamp

- 5-6.Hook type drum

- 6.Summary

What is a balancer?

This section explains the basic mechanism and role of the balancer.

Basic Mechanism of the Balancer

A balancer is a device that supports weight and reduces workload when a worker lifts or moves heavy objects, and is sometimes referred to as a assistive device or weight-assist component. No matter how heavy something is on a balance scale, if you put something of equal weight on the other side, it will balance. The balancer has the same mechanism, specifically generating force that balances the weight with a pneumatic cylinder, etc.

Role of the Balancer

The force required to lift a certain weight of object is the same no matter who lifts it, but the burden felt by it varies depending on the age and gender. In such cases, the balancer assists all workers to perform the same work with the same amount of burden regardless of the magnitude of the worker's strength. This can prevent lower back pain and injury of workers.

Mechanisms often compared to Assistive Devices

Here are some typical balancers.

CKD balancer (PowerArm)

One to three arms rising from the floor support heavy loads from below to assist in conveyance. The arm has built-in pneumatic cylinders and compressed air generates force proportional to the weight. The proximity of the heavy object and movable part (arm) has the advantage of making it easier for the operator to move the heavy object. There are fixed and movable types. The movable type can be moved with a dolly.

Arm Balancer

Arm balancers, combine a cylinder and link mechanism to suspend heavy objects with hooks, etc., or supports them from below. The payload tends to be large, but the balancer itself tends to be large because the dynamic and operating points are far apart. It has the disadvantage of being difficult to handle because of the inertia force applied when a heavy workpiece is to be stopped.

Hoisting Balancer

The hoisting balancer is shaped like a hoist (small crane), with a heavy object suspended from the hook. The arm balancer allows swiveling operation in addition to the X, Y, and Z-direction movement, while the hoisting balancer only allows Z-direction movement (lifting/lowering). To move the balancer in the plane (XY direction), separate installation of rails is required on the factory side.

Power Suit

Power suits are worn by people to support physically demanding work, mainly to protect the lower back. Although the payload is relatively small, it has the advantage of a wide range of motion and freedom of movement. Also, because they are wearable devices, they can be used in confined spaces where only a person can enter.

Industrial Robots

Industrial robots can automate (unmanned) work by replacing human movement with robots. However, there are a wide range of considerations, including the relatively high cost of introduction and the need for measures (fences and light curtains) to prevent people from approaching robots during operation to prevent hazards.

Balancer Selection Criteria

The following are the criteria for selecting a balancer.

Compactness

When considering compactness, it is necessary to consider the work area in the three dimensions of XYZ axes. To consider not only the plane (XY axis direction) but also the space above the human head (Z axis direction), such as ceiling piping. For balancers that can swivel, it is also necessary to confirm that there are no interfering objects within the maximum rotational radius.

Mobility

If you want to use a balancer for multiple tasks, consider mobility as well. A fixed balancer requires as many balancers as the number of jobs to be performed, but a mobile balancer can reduce the number of balancers.

Movable Range

The movable range refers to the range in which the balancer can be operated when installed at a certain location. Since the required movable range differs depending on the work, consider the widest possible range of motion for the assumed work.

Payload Capacity

The most important factor in balancer selection is payload capacity. The purpose of installing a balancer is to reduce the workload on the operator. If the balancer cannot achieve the target force, there is no point in installing the balancer.

Features of CKD PowerArm

Features of the CKD balancer "PowerArm" are as follows.

Operability

The PowerArm has two grips (one for each hand). The grips can be held firmly with both hands to move heavy loads, ensuring good operability. Utilizing low sliding air-controlled tail technology, it is so light and smooth that it can be operated even with one hand, making it easy even for people with relatively low strength.

Compact size

Balancers that can handle large areas generally tend to be large. However, the PowerArm features a link mechanism and cylinder that work in unison to support heavy loads from below, so it does not use overhead space (except when using attachments as described below) and is small in size compared to its working range. In addition, when storing, the arm can be folded down to make it even more compact.

Safety

The PowerArm is equipped with various safety measures. For example, the air supply valve is closed to keep the arm in its current position while transporting heavy loads (position locking with a block valve). For the mechanical lock specification, the rod of the pneumatic cylinder built into the arm is physically fixed with a slit. Therefore, there is not even a slight displacement due to air characteristics (compression/expansion).

Other safety measures have been implemented, such as locking the rotating section and a structure that prevents fingers from getting into the joint.

Example of CKD PowerArm Attachments

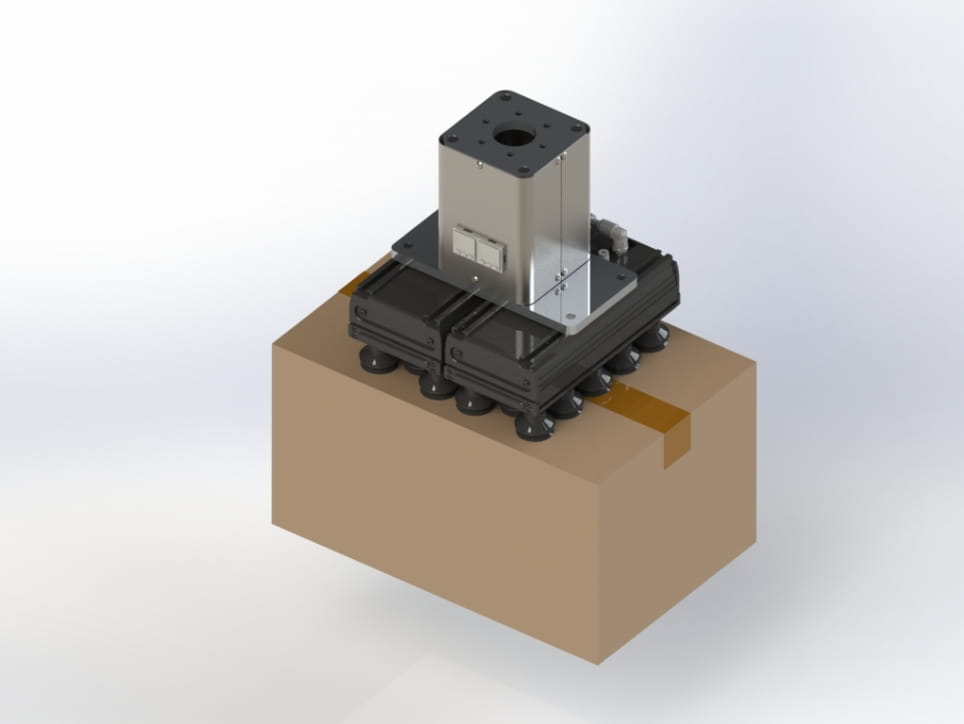

Suction of corrugated cardboard

A suction attachment can be used for transporting corrugated boxes (dedicated type for corrugated cardboard). Operation is the same as that of the bag suction attachment. Even if you try to release the suction during transportation, the operation is disabled by an interlock for safety.

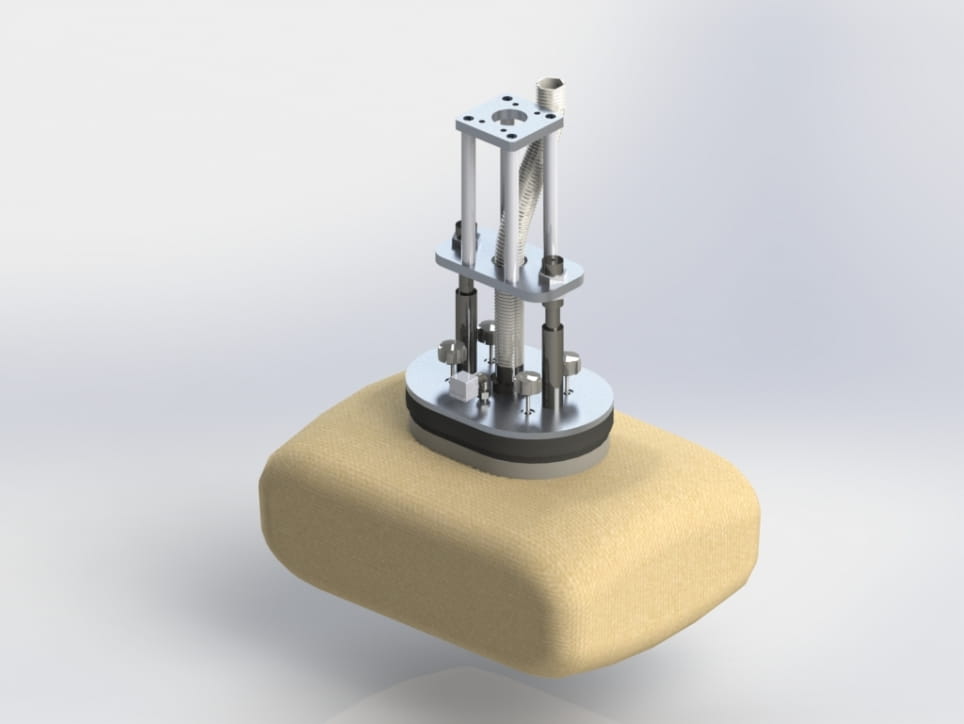

Suction of material bags

A suction attachment is used to transport heavy items in bags such as rice (dedicated material bag type). Place the attachment on the bag, and with a single button operation, suction begins. Since the permeability varies depending on the material bag, care must be taken when selecting an attachment.

Suction of 18 L cans

A suction attachment can be used for transporting 18 L cans (dedicated type for 18 L cans). The operation is the same as for other attachments. The attachment has a ring-shaped handle, making it easy to adjust the position when the attachment is grounded. The 18 L cans with handles can also be transported with hooks.

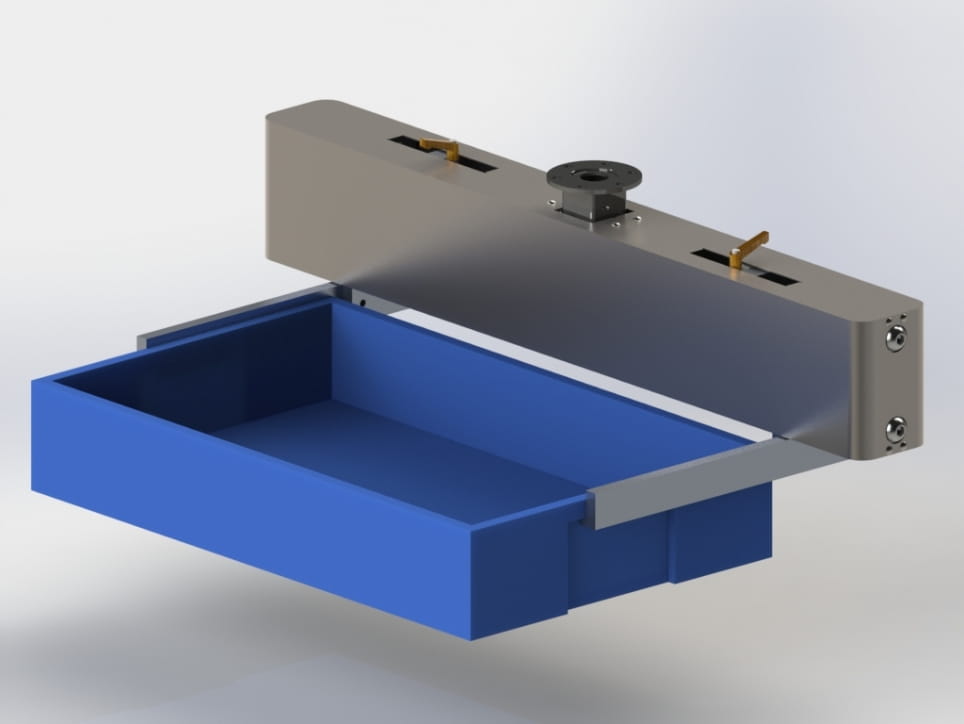

Container box container

An attachment that supports containers for parts and pallets (box containers) for foods. Two arms pinch and clamp the container and box container from the outside. Since the gripping width can be changed, a single attachment can be used for containers and box containers with different widths.

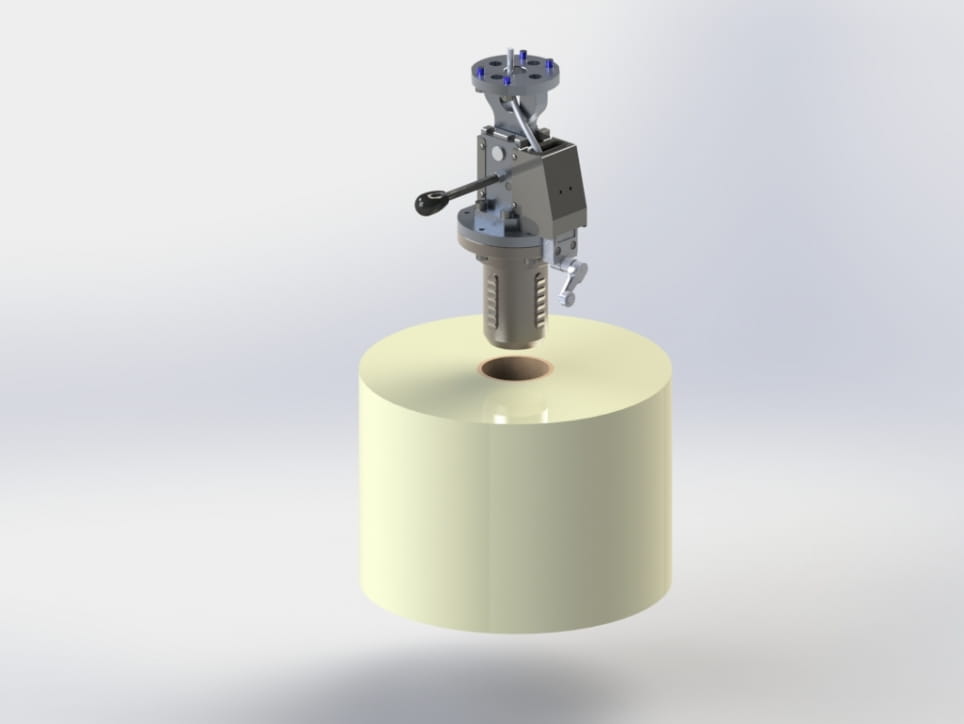

Roll material inner diameter clamp

An attachment that clamps the internal diameter can be used for transporting roll materials. Insert a thick rod-like attachment into the center of the roll material and operate the button to circularly spread the clamp parts. Loading is possible by rotating the machine 90 degrees in the air during transport (such as turning the upward one sideways).

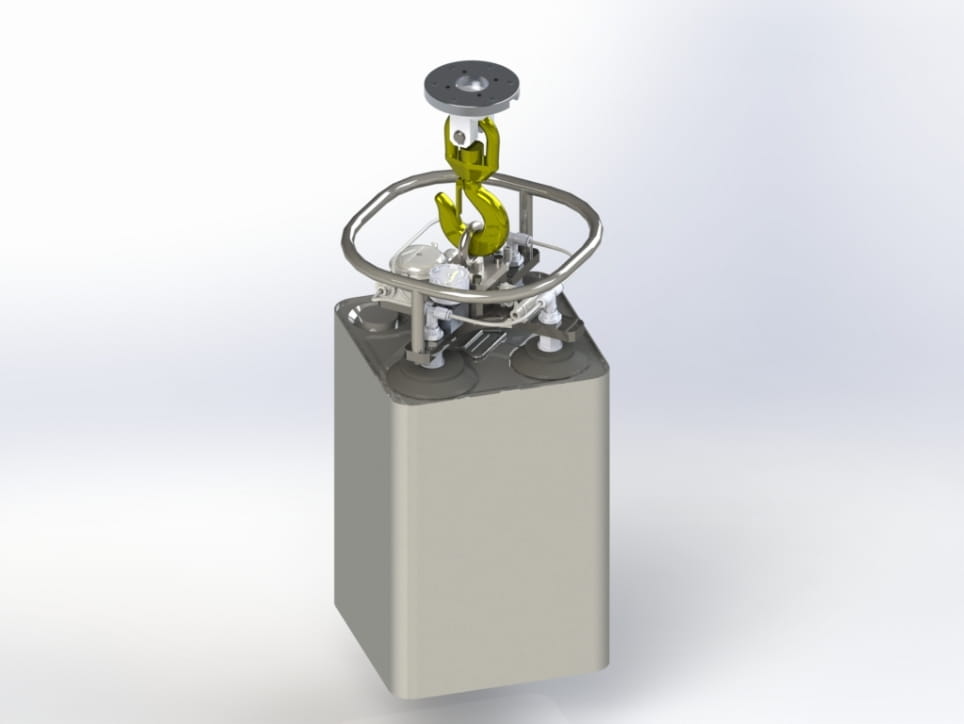

Hook type drum

At the base of two arms (attachments) that look like the crab's scissors are extended, the drum is grasped by the circumference of the upper part of the drum, and the drum body is supported by the tip of one of the fingers.

Summary

We introduced a balancer that reduces the burden on humans when transporting heavy loads. There are different types of balancers, each with its own Features. CKD's PowerArm products have been evaluated for their excellent track records, including variations suitable for various operations, various attachments, and safety-oriented design. We can make proposals suited to your individual work environment.

You can actually see and experience the movement of the PowerArm. If you would like to participate in a demonstration or a tour, please contact your nearest CKD sales office.