Conforms to the shape of the workpiece

Stop

We have been working on the movement and positioning of objects using motors, cylinders, and other drive sources. Recently, "motion control," a technology to control movement faster and more precisely, has become more advanced and easier to use.

On the other hand, there has been surprisingly little attention paid to the issue of keeping things stationary. What does the phrase to "hold things in place = to fix them so that they do not move" mean exactly?

It is one of the important roles of anchors in buildings, knock pins in machines, and so on, to hold things in place without being moved by external forces. However, in motion control, the positions where you can stop the movement is not always the same, and it is difficult to fix each time, don't you think? In addition, it is difficult to perform powerful fixing work, and safety measures during power failures and power consumption are also points of concern. However, if this "stopping" could be done easily, workability and efficiency will be improved.

This "stop" function is realized with the "Lock Unit UB Series".

What is the Lock Unit UB Series?

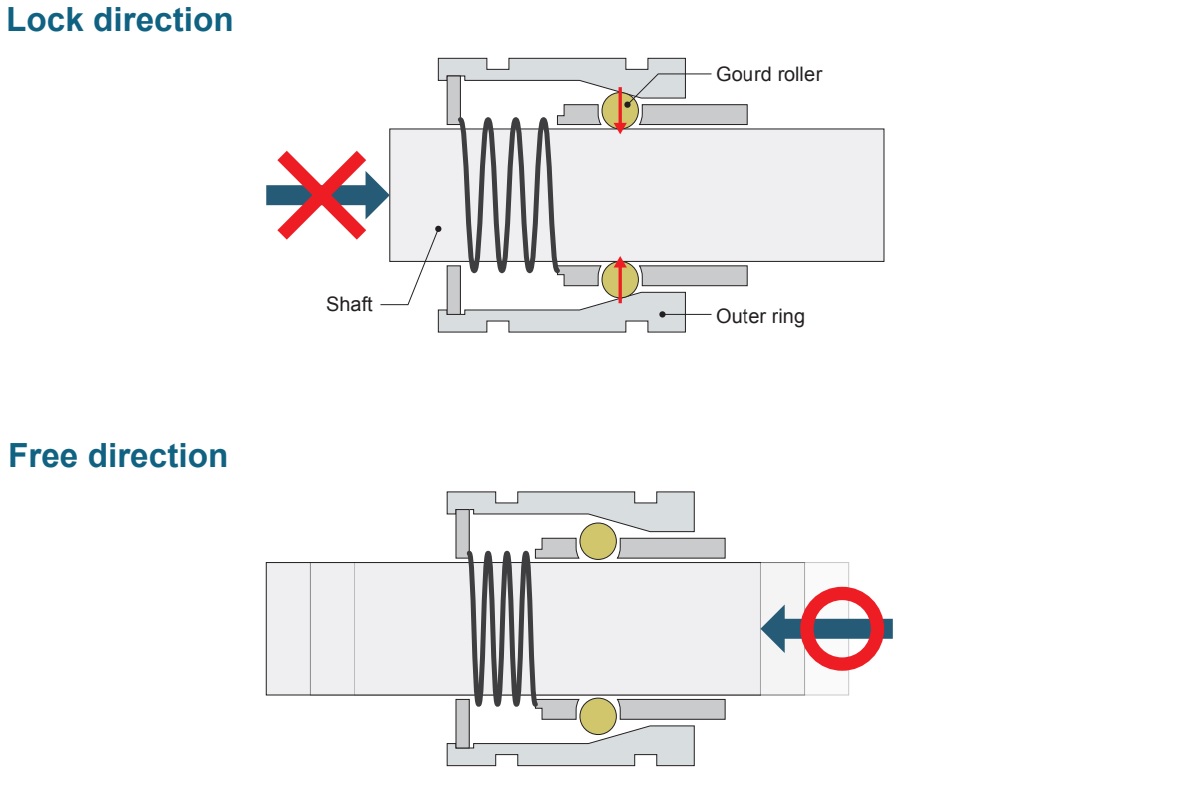

The UB Series is a specially shaped rolling part called the "gourd roller", which holds the guide shaft at an arbitrary position. The guided roller rolls into the wedge-shaped space formed by the shaft and outer ring to lock the shaft.

Since there is no rattling, highly accurate positioning can be maintained even under external force. Furthermore, the mechanical locking mechanism does not consume energy when stopped. Even in the event of a sudden power outage, the lock can be maintained without falling.

The vertical functionality of the locking mechanism allows the user to expand the range of performance by locking the machine strongly in the desired direction and freeing it in the opposite direction.

Imitate

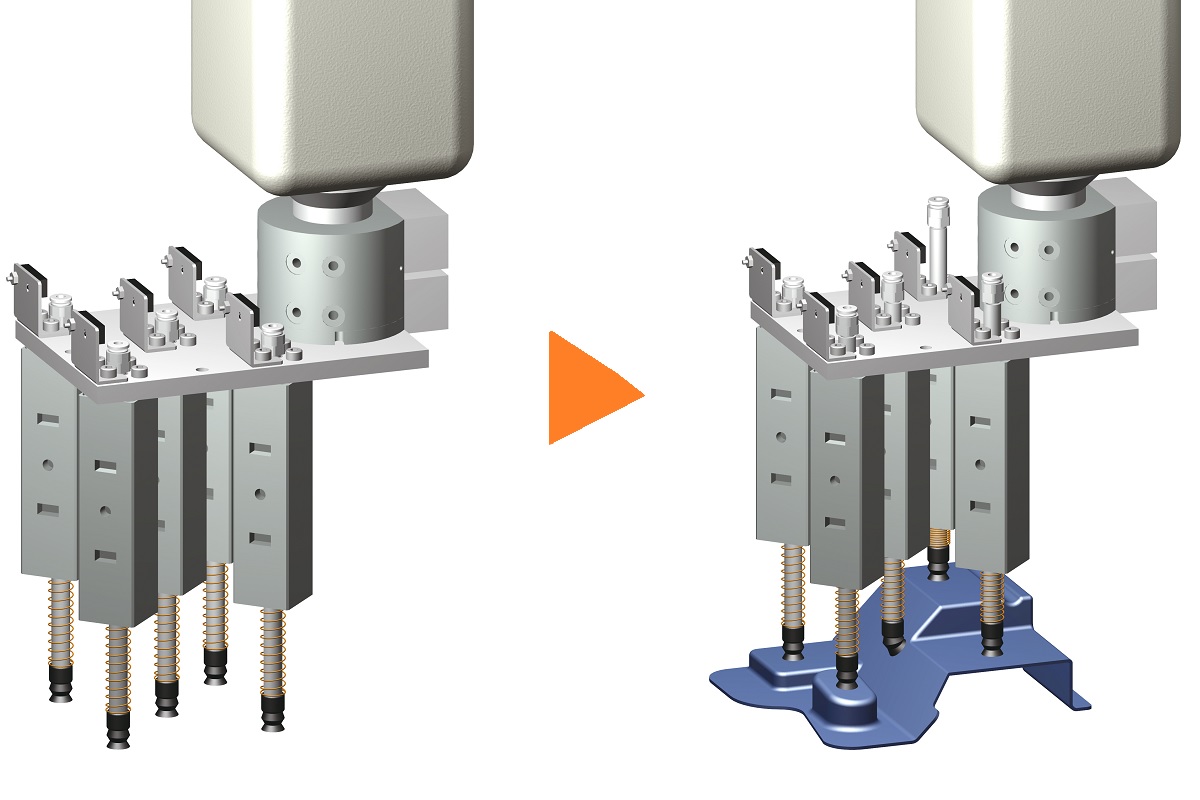

This function can be used to create a tracing jig.

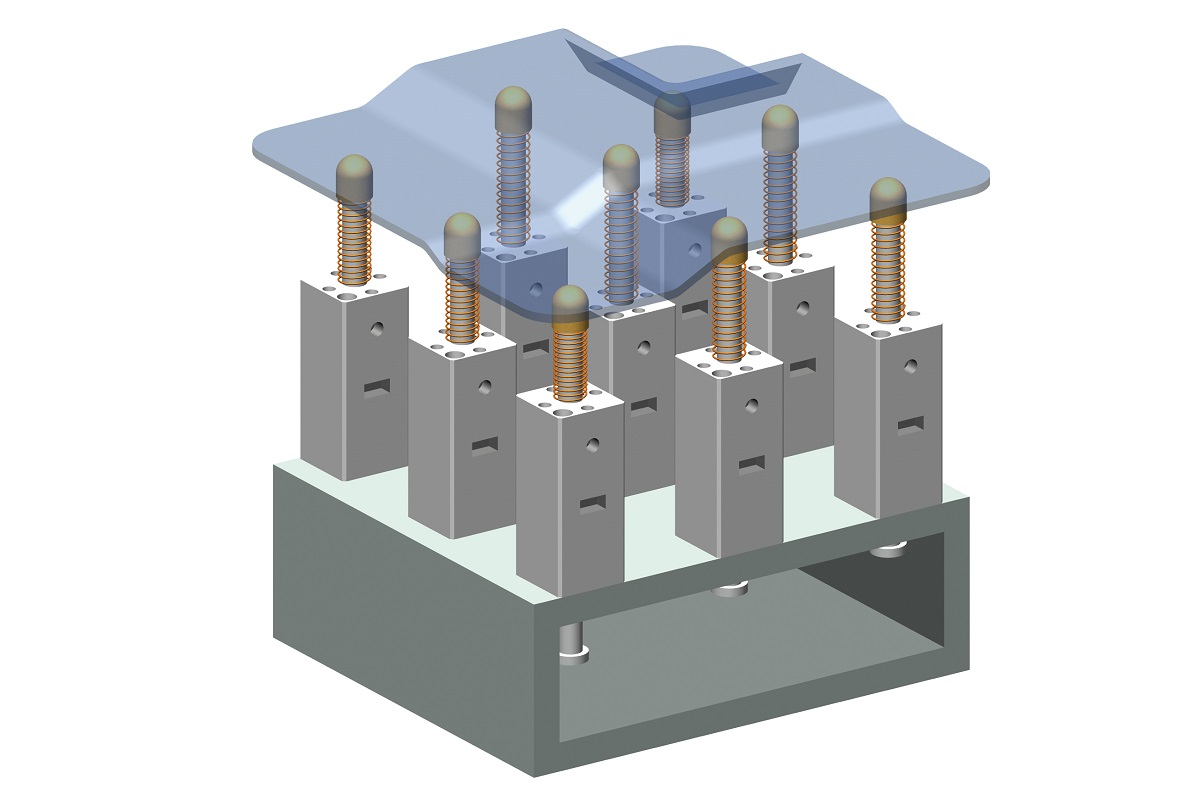

In high-mix low-volume production, it is necessary to prepare a jig for each workpiece to be handled, but the arrangement of jigs and the time and effort required to replace them can be burdensome. When the UB Series is used vertically, the position where the workpiece contacts the rod end is held, and a tracing jig can be made. By copying the shape of the workpiece, a jig can be made that matches the shape of the workpiece, and a single jig can be used for a variety of workpieces without the need to replace the jig. This significantly reduces equipment costs and maintenance hours.

▲Simply press a workpiece onto the shaft to copy the shape of the workpiece.

▲Tracks the shape of the workpiece by placing it on the shaft