Which actuator should be used, air or electric?

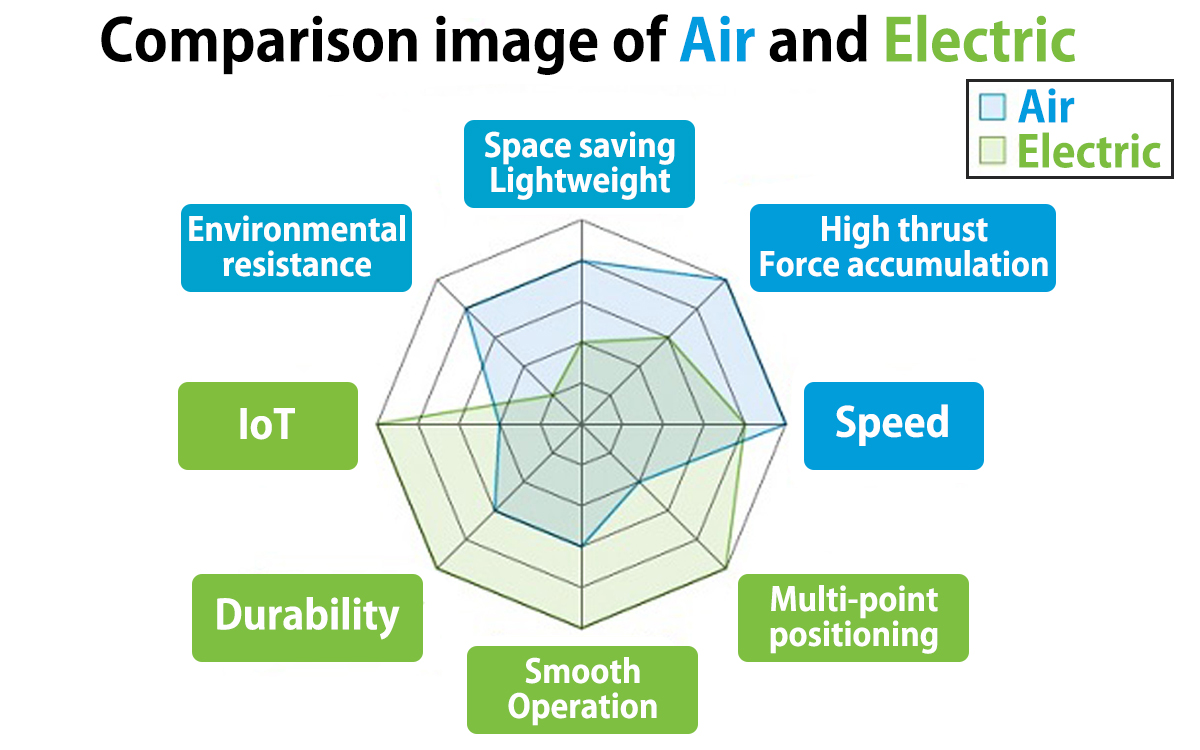

There are similar products between pneumatic and electric actuators. How does one decide to use pneumatic or electric actuators? Here, we introduce 3 points to consider when making a decision.

1:Type of workpiece

Electric actuators are more flexible in creating a greater number of stopping points with respect to the work size during transfer or inspection processes.

2:Environment

Where is it going to be used? Pneumatic actuators are more practical to use where space is limited, a lot of cutting oil or dust exist, or when environment resistance is required such as for outdoor use. They are also smaller and lighter than electric ones. However, when looking for quietness, or clean characteristics, we recommend electric.

3:Budget

Pneumatic actuators are less expensive than electric ones. If you want to keep initial costs low, choose pneumatic actuators. However, it would become necessary to incorporate pneumatic valves and consider the amount of air needed and maintenance.

We compared Pneumatic and Electric Motion in three ways: Cost, Space, and Positioning time.

Although CKD is a pneumatic components manufacturer, we also have electric actuators, allowing us to know the pros and cons of each. We offer the ideal actuator according to your needs and requirements.