Constant applied pressure.A Buffer unit that replaces spring buffers.

In most cases, the conveyance of small parts and substrates such as ICs and capacitors are done with adsorption units. Those using spring buffers need to have a look at our buffer unit with constant damping pressure and low dust generation.

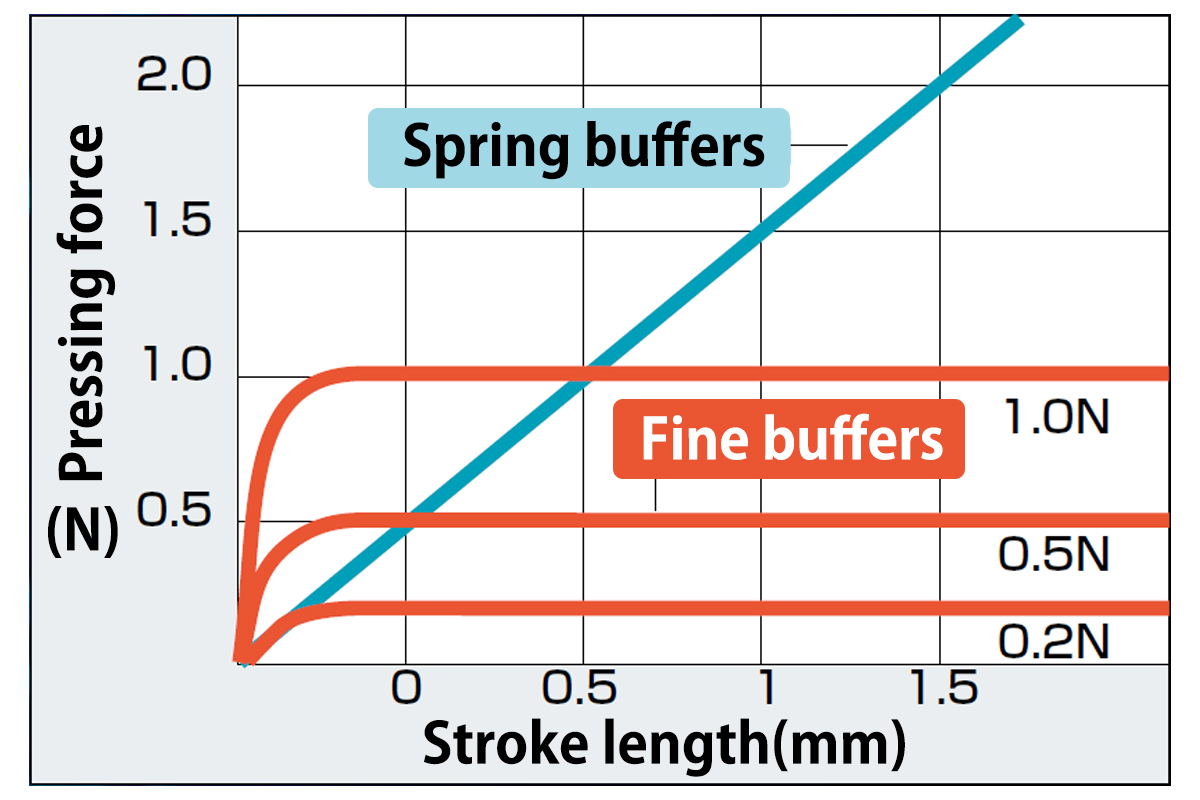

As metal spring buffers have varying pressure that is applied due to the stroke mechanism, caution is required in transporting parts with different heights. In addition, particles formed from contacting or rubbing of the spring may adhere to workpieces leading to defective products.

The issues associated with spring buffers are solved with CKD’s Fine Buffer FBU2 Series. Our FBU2 Series produces constant pressure by utilizing the attractive forces of magnets. Also, when a torque greater than the maximum holding torque is applied, the anti-rotation function returns to the home position. Since the thrust is generated by magnetic forces, you can expect a long service life.

Compared to spring buffers, there is no metal contact and the moving contact area is extremely small, resulting in low dust generation. Moreover, since the air flow path and sliding parts do not use copper based materials, the FBU2 can be utilized in the manufacture of rechargeable batteries.

Please take this opportunity to consider the FBU2. More FBU2 info here.