What is Nitrogen Filling? Applications in Food and Industrial Products, and Types of Nitrogen Filling Machines

Nitrogen filling is a technology utilized in a wide range of fields, from preserving the freshness of food and beverages to stabilizing the quality of industrial products. This article will explain the basic mechanisms and benefits of nitrogen filling, as well as specific adoption examples in food and industrial products, and the types of nitrogen filling machines.

What is Nitrogen Filling?

Nitrogen filling is a preservation technology used in a wide variety of fields, including food, beverages, cosmetics, and industrial products. By replacing the oxygen inside containers with nitrogen gas, it prevents quality deterioration due to oxidation and maintains the freshness, flavor, and appearance of products for extended periods.

In the food industry, it contributes to extending shelf life and maintaining flavor, while in industrial fields, it contributes to preventing oxidation and improving safety.

Common Applications and Benefits of Nitrogen Filling

Specific applications of nitrogen filling include usage in the following fields: In each field, the unique properties of nitrogen are utilized to contribute to maintaining product quality and improving safety.

Food Preservation

Nitrogen gas is widely used in food packaging and offers the following benefits.

Oxidation Prevention

Nitrogen is an inert gas that is chemically stable and does not easily react with other substances at normal temperature and pressure. By replacing the air inside food and beverage containers with nitrogen, oxidation is prevented, preserving flavor and quality.

Nitrogen is a colorless, odorless, and tasteless gas, so it does not interfere with the flavor of food.

It is used to maintain the quality of foods whose flavor is easily impaired by oxidation due to oxygen, such as potato chips, rice, various snacks, coffee beans, and wine.

Nitrogen is a gas approved for use under the Food Sanitation Act as a food additive with antioxidant properties.

Extension of Shelf Life

As mentioned earlier, nitrogen is an inert gas, and by filling it into packaging instead of oxygen, it prevents quality deterioration due to oxidation.

It is particularly effective as a method to prevent the degradation of easily oxidized components such as oils and fats, and vitamin C. It becomes possible to suppress food oxidation and maintain quality without using antioxidants such as sulfur dioxide and sulfites. This also leads to a reduction in the risk of accidental ingestion of antioxidants.

Furthermore, since nitrogen does not contain moisture, it can be expected to have an effect in suppressing the growth of mold and the like.

Nitrogen filling can extend the shelf life while maintaining flavor and texture, leading to improved consumer satisfaction and reduced food loss.

Industrial Applications

Oxidation Prevention

Metals and rubber used in industrial fields are also materials that are susceptible to the effects of oxygen.

Metals react with oxygen and moisture in the air, causing rust. Rubber is also a material that reacts with oxygen in the air, leading to a decrease in elasticity and hardening.

Nitrogen filling uses inert nitrogen gas to remove oxygen from the storage environment and prevent the progression of oxidation.

In the storage of metal parts and long-term preservation of rubber materials, nitrogen filling is highly effective in maintaining product quality. In addition, it can suppress the effects of humidity, preventing corrosion and rust, and further stabilizing the storage environment.

For example, in electronic components, nitrogen filling reduces the risk of rust and corrosion during long-term storage, and in rubber products, preservation with nitrogen maintains the flexibility of the material and minimizes performance degradation during use. In this way, nitrogen filling can be said to be a highly reliable choice as an oxidation prevention measure in the industrial field.

Control of Chemical Reactions

Because nitrogen is inert, it has the effect of suppressing chemical reactions.

In chemical tanks and UV curing processes, measures are taken to replace air with nitrogen for explosion protection and environmental maintenance in order to suppress the risk of reactions or explosions due to oxygen in the air. Nitrogen is also used for the preservation of products where oxidation is to be avoided, such as cosmetics, beverages, and medicines, playing an important role in maintaining quality.

Tire Inflation

*CKD's nitrogen filling is mainly for industrial applications, but usage examples for general daily use are listed for reference.

Because nitrogen molecules are larger than air molecules, the pressure inside tires is more stable, reducing the frequency of air pressure adjustments. Furthermore, it has properties that make it resistant to oxidation and corrosion, contributing to extending tire life.

In addition, because pressure fluctuations due to temperature changes are small, stable performance can be expected even during high-speed driving or in regions with large temperature differences, and by keeping tire wear even, it also leads to improved safety and fuel efficiency.

Comparison with Other Preservation Methods

Nitrogen filling is a very effective method for preserving food and products. Compared to other preservation methods, it has several unique advantages.

Vacuum Packaging

Vacuum packaging is a method of evacuating air from inside a container and sealing it.

This method is effective in preventing oxidation because it reduces oxygen, and is widely used for preserving fresh and dried foods. However, its microbial suppression effect is inferior to nitrogen filling, so there are limitations depending on the items to be preserved. In addition, vacuum packaging is vulnerable to physical pressure, and may be damaged by impact or handling during transportation, requiring caution in the selection of packaging materials and handling methods.

Vacuum packaging has the advantage of preventing moisture evaporation inside the packaging and is also suitable for foods and cosmetics where dryness is to be avoided, but combined use with nitrogen filling is sometimes recommended when it is desired to enhance the antioxidant effect.

Use of Oxygen Absorbers

Oxygen absorbers are substances that absorb oxygen inside packaging.

Iron powder, hydrous aluminosilicate (zeolite), salt, activated carbon, vitamin C, etc., are used.

Oxygen absorbers are easy to use and low in cost, making them a widely used method. For example, they are often used in the packaging of snacks and dried foods. However, the effectiveness of oxygen absorbers varies in duration depending on the packaging conditions and product characteristics, so there are limitations for long-term preservation.

In addition, when using oxygen absorbers in combination with shrink packaging, both the physical shrinkage due to shrink packaging and the volume reduction due to oxygen absorption by the oxygen absorber may cause excessive pressure on the internal product, potentially leading to damage, requiring careful design.

Frozen Storage

Frozen storage is a method of preserving food at low temperatures.

Frozen storage is an effective method for preventing food deterioration and enabling long-term preservation. However, there is a risk that food will lose moisture upon thawing, and the texture and flavor may deteriorate, so measures to maintain quality are necessary.

In this respect, nitrogen filling is highly compatible with frozen storage, and by filling nitrogen into the packaging before freezing, the effects of oxidation and humidity can be minimized. In addition, nitrogen also plays a role in preventing condensation during cooling, suppressing the formation of ice crystals on the surface of food. Therefore, even after frozen storage, the freshness and appearance of the food can be kept in good condition.

Furthermore, frozen foods that utilize nitrogen filling can maintain a more natural taste and texture even after thawing, which can be expected to improve consumer satisfaction. In this way, the combination of frozen storage and nitrogen filling is attracting attention as an innovative method to improve food preservability.

Types of Nitrogen Filling Machines

Nitrogen filling machines are devices for efficiently performing nitrogen filling, which is essential for preserving food and industrial products. There are several types of nitrogen filling machines, and each model has its own unique characteristics.

Nozzle Type Filling Machines

Nozzle type filling machines are devices for performing simple gas replacement packaging, and are used when filling gas into individual containers. This method is simple to operate and is suitable for small-scale production lines and specific products. In addition, depending on the type and settings of the nozzle, there is flexibility to accommodate containers of various shapes and sizes.

Chamber Type Filling Machines

Chamber type filling machines are efficient models that can fill multiple containers simultaneously, filling gas after evacuating the entire chamber. This method is suitable for mass production, and because of its high airtightness, it is possible to reduce the oxygen concentration to the extreme. It is also widely used for packaging food and pharmaceuticals where high-quality filling is required.

Gas Flush Type Filling Machines

Gas flush type filling machines are devices mainly for pillow packaging, which fill gas by blowing it into the packaging container. This method enables high-speed filling and is suitable for mass production lines. Furthermore, it is characterized by a wide range of packaging material options and the ability to handle a variety of products such as snacks and coffee.

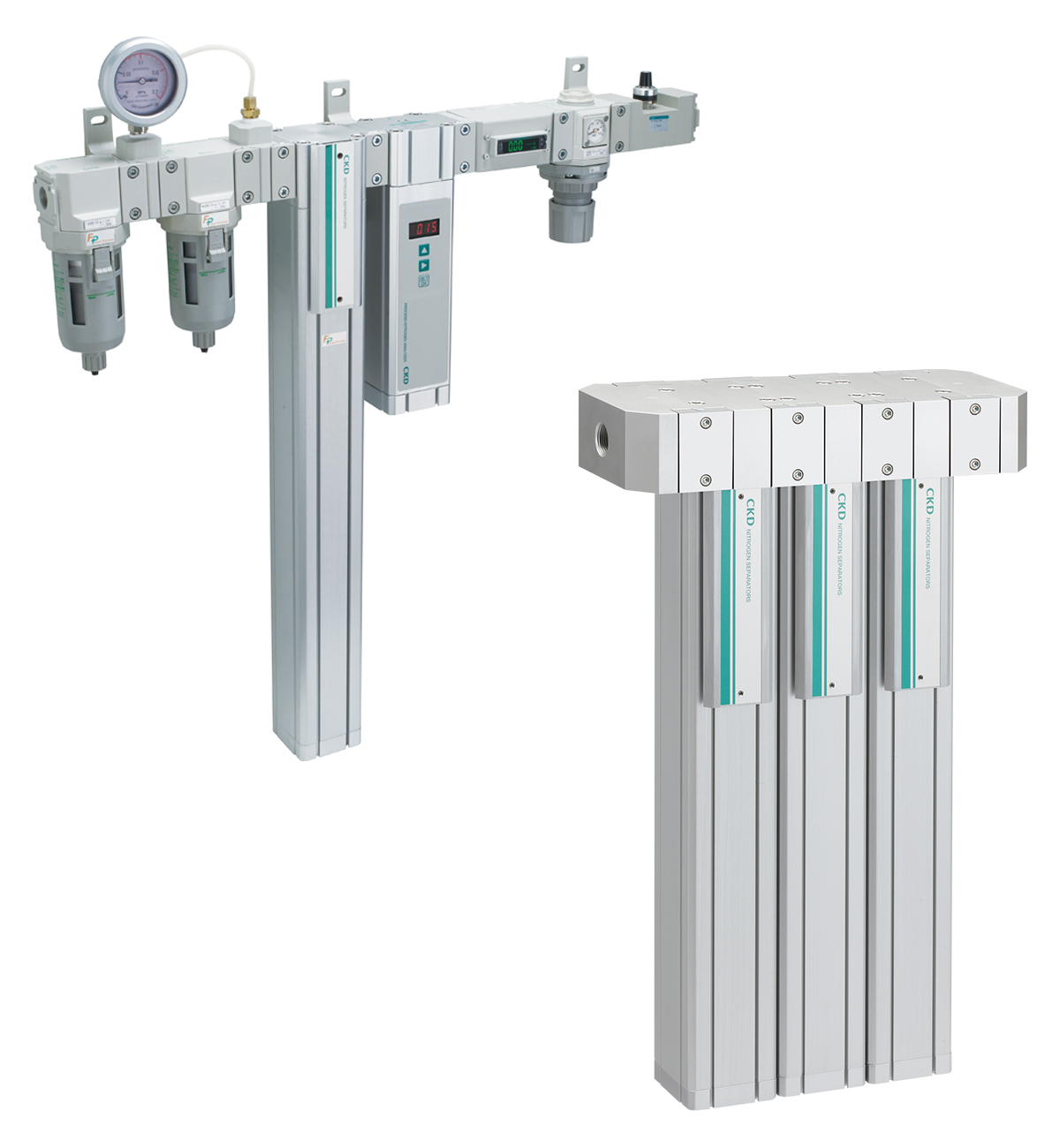

CKD Nitrogen Gas Extraction Units (NS and NSU Series)

Nitrogen filling machines are devices for efficiently performing nitrogen filling, which is essential for preserving food and industrial products. There are several types of nitrogen filling machines, and each model has its own unique characteristics.

| Features | Description |

|---|---|

| Supports Horizontal Installation | Newly supporting horizontal installation improves the flexibility of installation locations, such as dead spaces and built-in devices. |

| Freedom of Concentration | Nitrogen concentration can be selected in a wide range from 90% to 99.9%, supporting applications that require low-concentration nitrogen. |

| Easy Refinement | Nitrogen-enriched gas can be easily generated using hollow fiber membranes without requiring large-scale equipment. |

| Space-Saving and Labor-Saving | Piping can be simplified because it can be installed near the equipment, and an optimal system can be constructed according to the required flow rate. |

| Maintainability | No need to replace or replenish cylinders, and parts can be replaced with piping still connected. |

| Diverse Lineup | Choose the optimal model from 17 flow rates and 25 lineups, and constantly monitor the nitrogen supply status with inline oxygen concentration meters and flow meters. |

Please feel free to contact us.