What is Clean Gas Support?

Compressed air is indispensable in manufacturing sites, where it is used for various processes in various industries, such as air blowing and conveyance, as well as for power. In recent years, measures related to food safety have been discussed in the food industry, including revisions to the Food Sanitation Law and international standards. While CKD is not a food manufacturer, various components products such as filters, regulators and valves are used in food manufacturing processes, and we would like to contribute to food safety as a company involved in the food supply chain. We would like to introduce our newly started "Clean Gas Support", a support service to measure compressed air using JIS-compliant methods. It is very important to know the cleanliness of air, not only in the food industry, but also for customers who have problems with air quality.

1. Revision of laws and standards in the food industry

Revisions to the Food Sanitation Law and international standards have included the institutionalization of HACCP and the introduction of a positive system for measures related to food safety. In addition, ISO 22000 is an international standard for food safety management systems, which establishes international standards for "systems for managing food safety" and visualizes them as common understanding. FSSC 22000 is an acronym for Food Safety System Certification 22000, an international standard management system for implementing more robust food safety management based on ISO 22000 approved by GFSI (Global Food Safety Initiative).

2. What is HACCP?

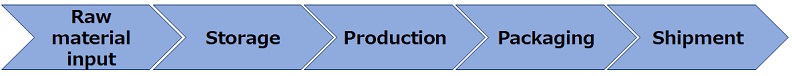

HACCP stands for "Hazard," "Analysis," "Critical," "Control," and "Point," and is commonly referred to as HASAP. It is a method of hygiene management that analyzes various hazard factors in each process from the acceptance of raw materials to finished products, and manages and monitors processes that are particularly important for preventing and reducing those hazards to ensure safety. In June 2021, the HACCP system was fully implemented. Based on this, management and monitoring not only improves quality and safety, but also enables sanitary management based on clear standards, allowing quick identification of the cause and reduction of risk in the event of an issue.

3. What is Clean Gas Support?

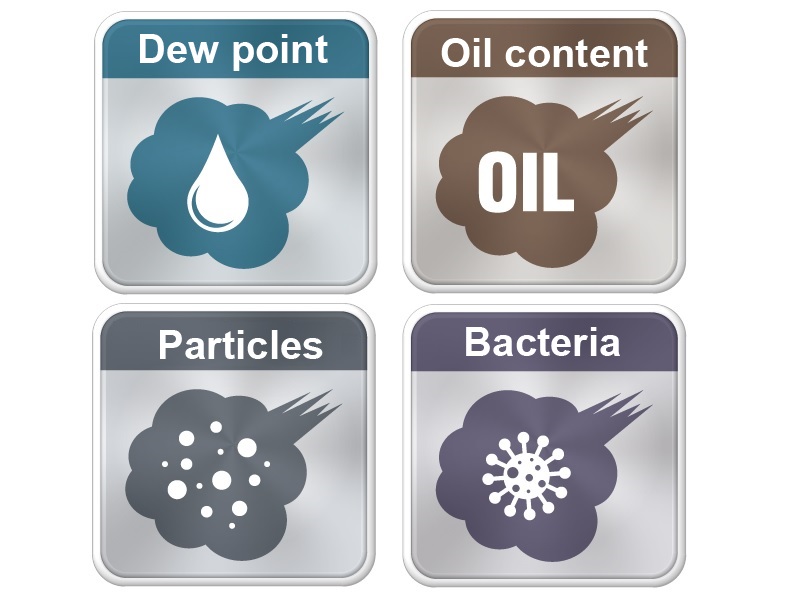

Clean Gas Support measures the dew point, oil content, particles, and bacteria of compressed air, and produces a report. Based on the measurement results, the HACCP coordinator also provides advice on pneumatic circuits. The revision of the Food Sanitation Law and international standards has now added a statement that dust, water, oil, and bacteria must be controlled for gases that come into direct or indirect contact with food (e.g., compressed air), which were not previously subject to control. What are some of the gases that come into direct or indirect contact with food? There are many, such as filling with nitrogen gas to prevent oxidation, and using air blowers for conveyance, removal of foreign matter, and sorting. After the revision, measurement of cleanliness and numerical control of gases used are required, but no specific measurement methods or standard values are described. When compressed air is used, cleanliness grades are required to match the equipment and products (food, medicine, etc.) used, so CKD uses not only its own methods, but also the contaminant measurement methods and contaminant concentrations specified in JIS B 8392 "Compressed air - Part 1: Contaminants and cleanliness grades" and CKD uses the results of these measurements as a guideline. Based on these results, we have also proposed components to improve air quality. We provide a one-stop solution for everything from air components product proposals to quality control.

4. Summary

In the future, compressed air management will be more important than ever in the food industry. The most important thing to pay attention to in the food manufacturing process is the presence or absence of bacteria. However, some customers do not recognize the presence or absence of bacteria in the compressed air used in each process. This Clean Gas Support is not limited to customers in the food industry. In addition to developing components for food manufacturing processes, CKD has established consulting services for gas management. This support is also useful for customers who need clean gas, or who have trouble with oil-sensitive processes such as laser processing, or who have a lot of condensate. Please take advantage of the Clean Gas Support to first understand the condition of your air.