The answer to realizing high speeds and short tact times.

Equipment is being required to provide higher speeds, higher responsivity, shorter tact, and more rapid speeds toward cylinders and shock absorbers. As a result, shock absorption characteristics and service life are challenges. Here, you’ll be introduced to the pneumatic cylinder shock absorber technology.

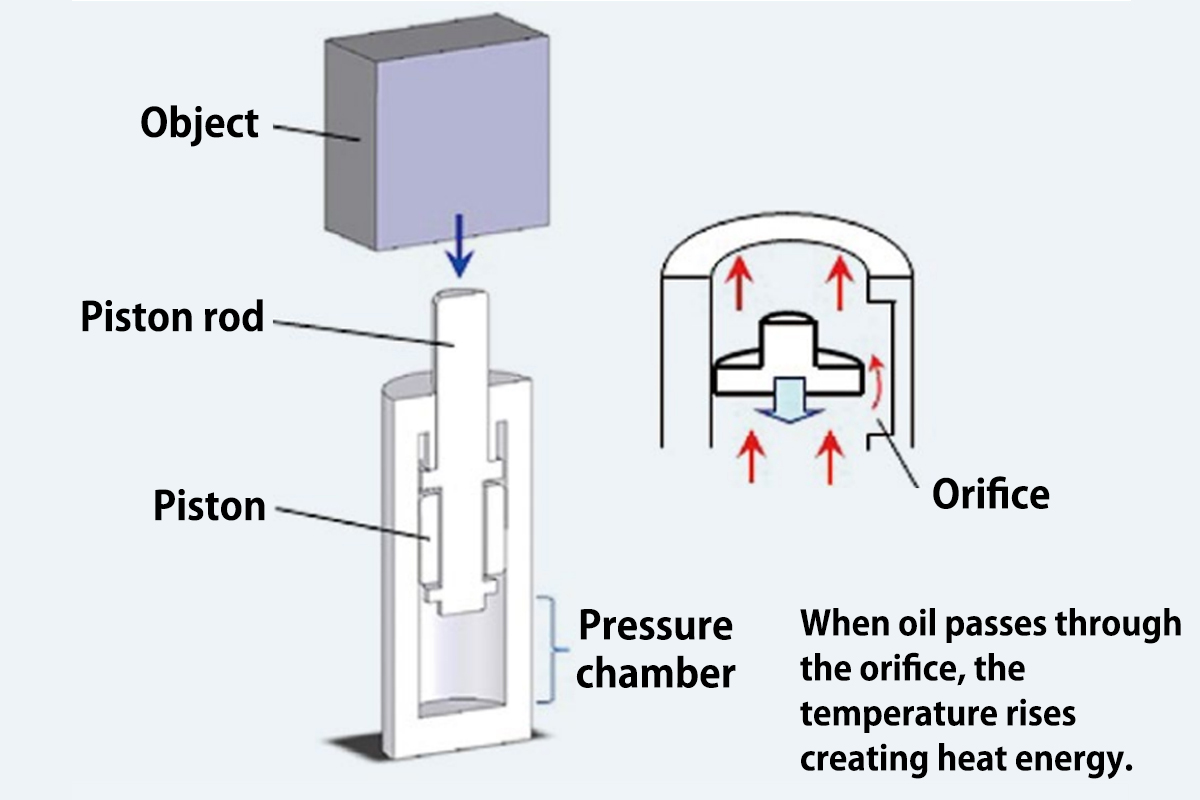

To ease the impact of pneumatic cylinders, rubber and air cushions are commonly used. However, shock absorbers are used for guided and rodless cylinders when the impact is large.

The ability of the shock absorber is greatly affected by changes in energy absorption characteristics due to air bubbles inside the oil.Shock absorbers for linear slide cylinder SKL Series has established CKD’s production technology to reduce internal air bubbles, making operation times shorter with higher durability at the same time.

By all means, try this series.