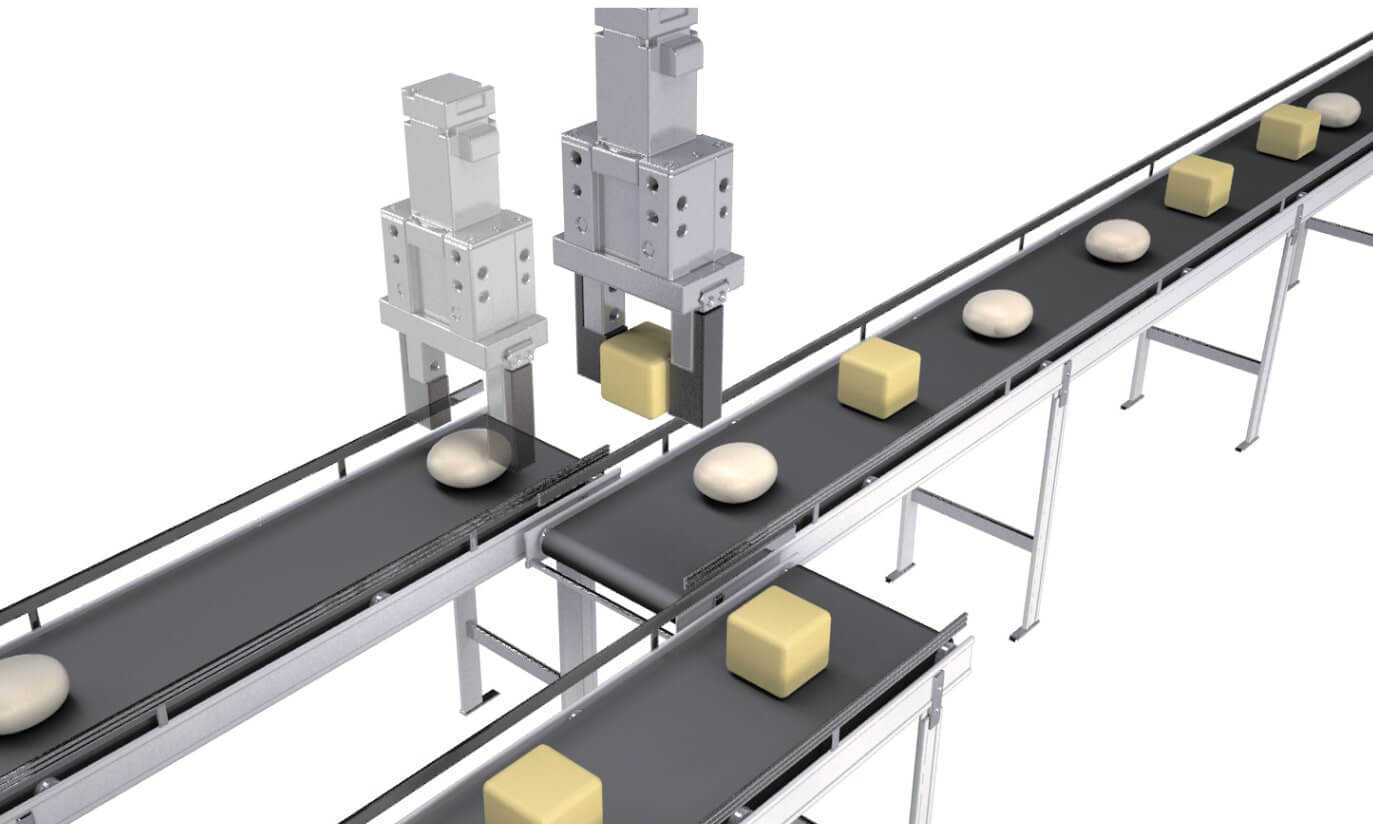

Gripping (soft handling/short strokes)

/ FLSH・DLSH

Requests and Issues

We are currently using an air hand, but we want soft handling because the workpieces are often damaged.

To provide a soft handling system, electric grippers are being considered, but since they are larger, heavier in weight than air hands and uncompatible mounting, electric grippers that are as compact and lightweight as possible are required.

Recommendations

The FLSH Series is recommended for multiple workpieces and DLSH Series for single workpieces.

FLSH Series

DLSH Series

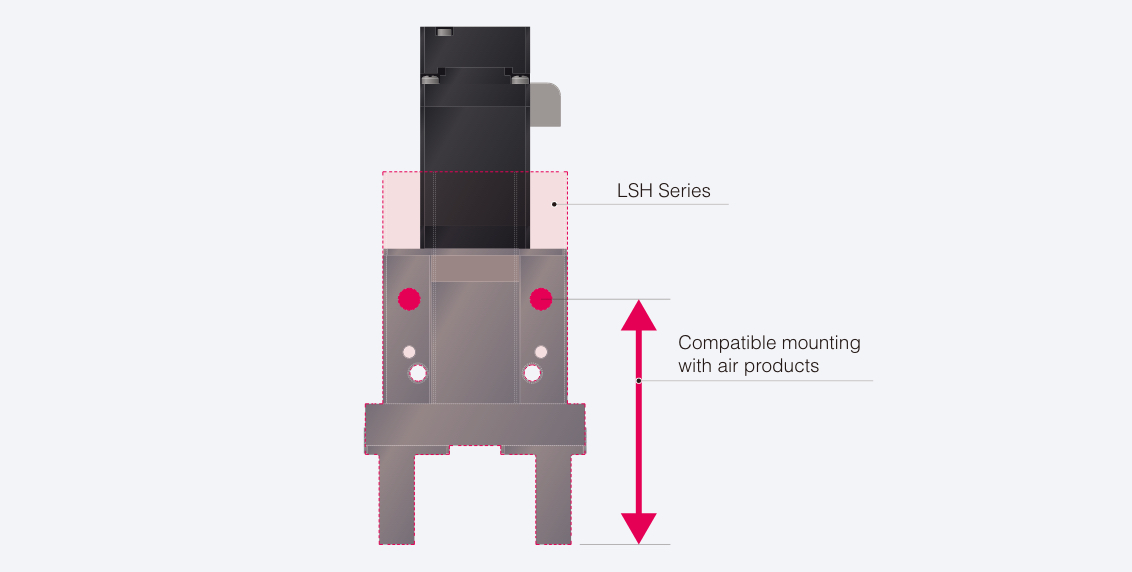

The 2-Finger Gripper FLSH Series is compatible with the pneumatic components Linear Slide Hand LSH Series and has the same gripping force, so it is possible to replace the pneumatic components with electric motion components without increasing the components size.

In addition, compared to the LSH Series, it is extremely lightweight, weighing a maximum of 130 g more.

As it is an electric gripper, it enables not only soft handling but also easy workpiece identification based on current position information.

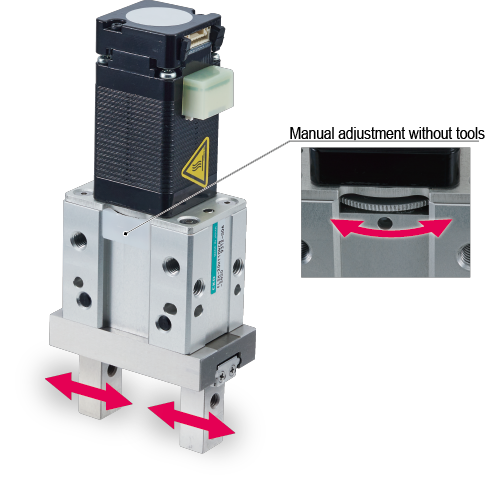

The FLSH Series has a manual operation mechanism enabling tool-free operation on the front of the body.

The finger position can be easily adjusted at equipment startup, and to remove and install workpieces held by the self-locking mechanism.

Since it is connected to the ECG Series controller and the ECMG Series multi-axis controller, which are common to other types of actuators, the controllers can also be standardized, contributing to reductions in inventory and man-hours required for management.

You can choose from a total of five interfaces: PIO, IO-Link, CC-Link, EtherCAT, and EtherNet/IP.

※For ECMG, select from CC-Link, EtherCAT and EtherNet/IP, PROFINET.

The DLSH Series 2-Finger Gripper is specialized for positioning between two points, suitable for single workpieces.

The body is equivalent to that of the pneumatic Linear slide hand LSH Series and can be easily replaced with a motorized component.

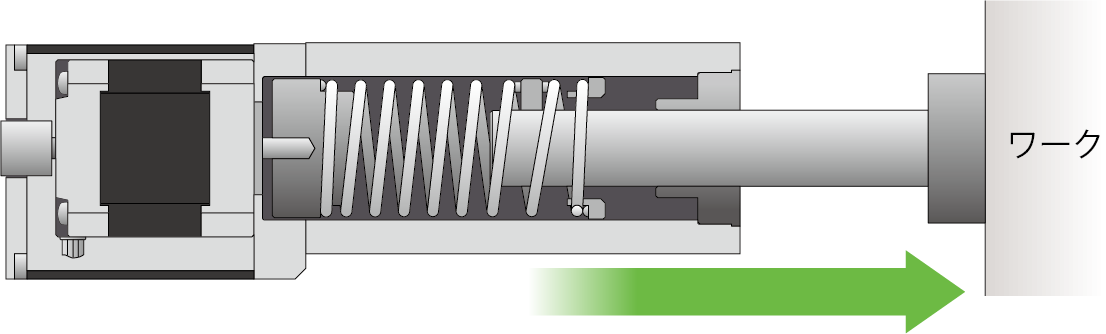

The drive mechanism uses a spring drive system in which the motor rotates the spring.

The spring mechanism eliminates the need for constant speed operation during pressing and reduces impact to the workpiece.

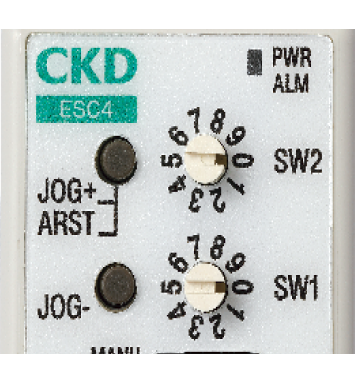

cylinder switch

rotary switch

The DLSH Series requires no complicated programming and connects to the ESC4 Series controller with only three inputs.

Setting with a dedicated tool is not required.

The stop position can be adjusted with the cylinder switch on the actuator body, and the speed and acceleration/deceleration can be adjusted with the rotary switch on the controller side, and can be handled as easily as Air components.